It was the middle of summer, and an abnormally warm summer in which all of the Citizens Energy Group District Cooling System’s chillers and cooling towers would be needed to produce chilled water. The vertical lift pumps (VLPs) are installed outside near the main plant cooling towers. As anyone familiar with cooling towers knows, these are not typically located near well-traveled paths. The motor for the VLP in question was a U.S. Motors Titan, 600 hp at 900 rpm with antifriction bearings.

A request was submitted by the area personnel to perform vibration analysis for determination of severity and actual cause of the reported vibration and noise. After reviewing necessary information, the machine setup was added to the legacy vibration program and a set of readings, including spectrums, was taken.

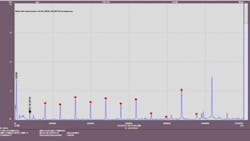

Vibrations were excessive from the motor opposite drive end. As can be seen in the spectrum, the harmonics of ball pass outer race (BPOR) frequency were present (Figure 1).

Figure 1. Vibrations were excessive from the motor opposite drive end. As can be seen in the spectrum, the harmonics of ball pass outer race frequency were present.

After comparing historical readings on a similar motor, we proceeded to confirm the excessive vibration readings using ultrasonic technology. This technology is a great tool for detecting and evaluating antifriction bearing faults. To listen to and compare normal motor bearings to potentially abnormal motor bearings, the ultrasonic meter sensitivity was set to mid-range decibel (dB) readings for the normal bearing. When the ultrasonic meter was used on the potentially defective bearing, the amplitude of the dB reading went off the meter’s scale. Scale adjustment had to be increased before the dB would fall within the same dB range as the measured normal bearing. The abnormal bearing dB evaluation proved significant abnormal ultrasonic noise was present. Comparisons of like motors are a common practice in industry. Although trending of the dB reading is not a normal part of our predictive program, confirmation of abnormal bearing condition was easy. The damage and sound of a defective bearing is somewhat unique and having to set the sensitivity to a higher scale to achieve the desired dB reading for comparison made determination of abnormal condition straightforward. Of course, the amount of bearing damage also provided enough evidence.

A confirmation vibration report was assembled with spectrum identifying the motor opposite drive end bearing had an outer race fault.

Motor repair was completed on a holiday when cooling load was at its minimum.

Figure 2. The spectrum after completed repair and bearing harmonics have been eliminated confirms acceptance.

Another set of vibration readings were taken to confirm acceptance of completed repair work. Figure 2 is the spectrum after completed repair and bearing harmonics have been eliminated.

The bearing that was replaced was saved because of the unusual amount of damage found to the bearing outer race. The crack in the outer race was catastrophic in nature and the analysis determined severity and location (Figure 3).

Figure 3. The crack in the outer race was catastrophic in nature and the analysis determined severity and location.

If not for the excellent teamwork by all involved, this could have resulted in an extreme repair cost and not a cost-avoidance savings. Todd Fuller, facilities manager, chilled water plants, itemized the potential cost of motor failure from a lack of identification, analysis, and repair.

| Donald Jones is predictive systems specialist at Citizens Energy Group in Indianapolis, Indiana. Contact him at [email protected]. |

The actual cost of the bearing replacement was $9,500, including contractor, crane rental and in-house labor on holiday pay. The estimated cost of a rebuilt motor, assuming the continued operation resulted in damage, is between $35,000 and $40,000, with an estimated two weeks to rebuild the motor.

The cost of rental equipment to replace the 5,000 tons of production equipment would be $160,000 over two weeks, as well as a $20,000 rental equipment cost of installation and removal. The estimated amount of revenue lost waiting for rental equipment to be installed, assuming three days, is approximately $300,000. Costs can quickly escalate, should such a vital piece of equipment be lost during the peak season.

To learn more about ultrasound and vibration analysis, read Combine vibration monitoring and ultrasound for more cost-effective predictive maintenance