Best practices for predictive maintenance of bearings

From toy skateboards to fidget spinners and industrial machinery, bearings are everywhere. Rotating machinery counts for the highest usage of bearings within the industrial sector due to various loads and speeds, and the biggest challenge in industry today is maintaining those bearings.

Bearings can be a technician’s best friend or enemy—like with jewelry, care must be taken to maintain condition within storage and use. Various methods exist to support bearing life and accomplish L10 (the number of hours in service that 90% of bearings will last). However, talent and labor shortages contribute to bearing failure, because as stated in the book, Don’t Just Fix it, Improve it!, 84% of all defects occur due to careless work habits.

What does it cost to maintain a bearing? Measuring variables include the bearing’s cost, the time spent replacing it, and the amount of labor to replace it out in the field. Each bearing will be application-specific; however, generalizations could be made across a manufacturing plant as there are hundreds or thousands in a facility. This article offers some practical tips on how to implement predictive maintenance technologies to help overcome bearing failures and reactive work habits.

Reactive, preventive, or predictive?

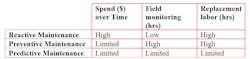

Maintenance is a business within itself, and it has many forms: reactive, preventive, or predictive (and/or proactive). The type of maintenance on certain equipment or assets within a manufacturing facility varies because of the effort needed to maintain the culture in which you maintain your equipment—in this case, bearings. Each has its advantages and disadvantages as shown in Figure 1.

- Reactive maintenance (direct replacement) requires a significant spend over time, a significant amount of time to replace the bearing, and limited time spent in the field monitoring it.

- Preventive maintenance (limited replacement of equipment) takes significant time, limited spend over time, and high labor resources.

- Predictive maintenance (limited replacement of equipment) only needs limited time, limited spend over time, and limited labor resources to support overall bearing life.

The value proposition of predictive maintenance is taking industrial maintenance by storm as technology has become more cost-effective and easier to access. Embracing a predictive approach often means that your teams will shift from dealing with severe bearing failures to supporting minor corrective actions within a manufacturing plant.

Vibration monitoring and ultrasound analysis

Lubrication is a hot topic for bearings, as industry knowledge indicates approximately 80% of bearings fail prematurely due to inadequate/inappropriate lubrication. To overcome this, predictive technologies are constantly evaluated for use throughout manufacturing plants to promptly monitor bearing health and proper lubrication.

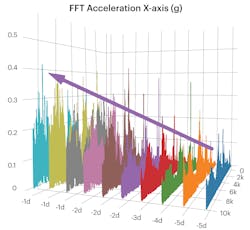

The two most prominent predictive technologies for supporting bearing life are vibration/temperature monitoring and ultrasonic monitoring. (For slow applications <10 rpm, thermal imaging may be leveraged to identify premature bearing fatigue.) Vibration analysis can identify where defects occur through analysis of the full spectrum, aka FFT (Fast-Fourier transform). Not all technology is able to provide this feature—however, where it does exist, this data is helpful. Through analyzing these spectrums and leveraging processing techniques, bearing fault frequencies overlayed with the spectrum data are the first indication of bearing health.

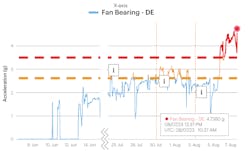

An indication through vibration analysis of inadequate lubrication is called haystacking. In a fan application, the graph would show increased amplitudes between 2,000 and 3,000 Hz before lubrication and then a significant decrease in amplitudes after appropriate lubrication is applied. Another example of a bearing requiring attention from inadequate lubrication is shown in Figures 2 and 3, an overall acceleration chart and a 3D FFT chart, respectively. The fault identified was categorized as a dry bearing which triggered a re-lubrication event.

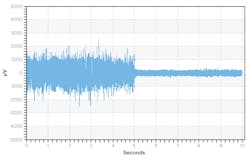

Ultrasound is another useful technology to support overall bearing health. Like vibration analysis, it measures decibels (dB) and how much sound the bearing emits. Ultrasound signals are by definition outside of the audible range of human hearing, typically between 20-20 kHz, but tools are available to convert the signal to a sound that is recognizable to people.

Figure 4 illustrates this with an ultrasonic spectrum displaying the state of a bearing both before and after lubrication. If a bearing’s cavity is empty or the bearing requires grease on the elements or surfaces, the grease will work to fill in where it is needed. Inadequate lubrication is costly and can create unsafe working conditions (higher operating temperature of rotating machinery, collapsed seals, energy loss, equipment failures) and re-work.

However, planned maintenance routes for greasing often leads to over greasing, increased spend of lubricants over time, blown bearing seals, and failed bearings. Additionally, we create a culture of “more is better” instead of just the perfect amount at the correct dosing interval. If over-lubrication occurs, the bearing begins to transition to display similar characteristics—higher dB—of not having enough grease.

The sweet spot is in between these extremes, where ultrasonic signals are eliminated via the application of just the right amount of lubricant. Evaluating the time and resources spent on lubricating bearings alone will justify equipment and proper lubrication training. This does not even include the cost of the bearing replacement. Technology is here, so let’s use it.

Leaveraging technology

Concluding with a business case, here are the financials of a single-bearing issue caught and resolved before failure could occur—based on the data shown in Figures 3 and 4:

Type of failure: Lubrication

Cost avoided: $19,000.00

Downtime avoided: 8.00 hours

Leveraging technology will enhance a bearing’s life and benefit a plant’s maintenance staff. We live in an era of insufficient human power to perform routine/mundane tasks. Technology lets us replace some of these tasks with tools and trained workers to add value every day, not including the cost savings generated with each bearing save. Both vibration and ultrasound analysis provide an adaptable and scalable approach to maintaining bearings. Choosing the correct tool and performing the right action takes thought; there are resources to help, and it often starts with a conversation.

1 Winston P. Ledet, Winston J. Ledet and Sherri M. Abshire. 2009. Don't Just Fix It, Improve It! A Journey to the Precision Domain. Reliabiltyweb.com, p.92.

About the Author

Ed Duda

CMRP

Ed Duda is the senior manager of P2MRO at Motion. He has a multidisciplinary background in operations and maintenance excellence, with several key roles for DTE Energy, Freeport-McMoRan Inc. and Des-Case Corporation. Duda has extensive experience in operational and maintenance strategy execution, lubrication program development and deployment, and applying Industry 4.0 technologies within manufacturing facilities. He has traveled across the United States over the last ten years and continues to drive continuous improvement projects. Duda holds a Master of Business Administration, a Bachelor of Science in Chemical Engineering, and several certifications (CMRP, ICML MLT I and MLA I/II). For more information, visit Motion.com.