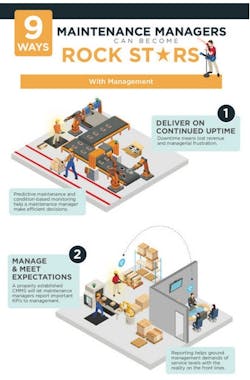

How to become a maintenance rock star in 9 steps

With predictive maintenance and a CMMS, maintenance managers can nurture their teams by shaping a less stressful, less reactive day-to-day environment. Instead of responding to one emergency after another in a seemingly random and uncontrolled manner, days and even weeks can be planned down to the hour.

By switching to a predictive maintenance and condition-based monitoring model backed by a CMMS, asset histories can be tracked. This lets maintenance managers make decisions that are more strategic and to prioritize work more efficiently to ensure the right maintenance, at the right time, for any given asset.

A recent infographic, created by Accelix Community, conveys the different ways maintenance managers can become rock stars with management, with their peers, and with teams by using predictive maintenance strategies and a CMMS.