The 7 guiding principles of a Maintenance 4.0 strategy

It is not uncommon for organizations to struggle with many issues related to digitalization. With the hype around digitalization at fever pitch, it is easy to become overwhelmed by the multitude of options available in the marketplace. But the strongest contributing factor to implementation challenges is a failure to devise a strategy for an extensive period of uncertainty.

Formulating a Maintenance 4.0 strategy is not easy. An aggressive strategy based on overinvesting in unproven technologies or a conservative strategy of merely waiting on the sidelines are unrealistic options.

Guiding principles

The seven guiding principles for a Maintenance 4.0 strategic plan are:

1. Invest based on the business case. The primary obligation to shareholders does not change just because of the changes occurring within the manufacturing arena. What does this mean from a practical perspective? Strategic choices require due diligence and investments must be made based on expected returns to the business. If you cannot justify the investment to your shareholders, it should not be made.

2. Take an incremental approach. Adopting Maintenance 4.0 does not mean eliminating existing processes and technologies. Yes, there are legacy systems that are no longer effective, but the default should be to adopt existing practices. It’s likely that your organization already uses some so-called Maintenance 4.0 practices. Big bets on new, still-evolving product categories should be minimized.

3. Upgrade existing maintenance practices. In support of incrementalism, industrial plants should evaluate maintenance best practices that can be adopted in parallel to Maintenance 4.0.

4. Adaptability. The fast pace of innovation has significant implications for industrial plants adopting a new strategy. Will a solutions breakthrough that occurs in 2020 be redundant by 2025? An accelerated speed of change is the new normal, and companies must identify ways to incorporate new Maintenance 4.0 solutions while minimizing disruptions to operations.

5. Data as an asset. Big data is the oxygen of Maintenance 4.0. Although vast amounts of data are generated by sensors embedded within industrial machinery, most of the data is not yet used today. A guiding principle for a Maintenance 4.0 strategy is that data governance practices must be instituted and the underlying value of operational data should be captured.

6. O&M collaboration. Successful implementation of Maintenance 4.0 cannot happen unless the views of plant-level employees are considered as part of the requirements process. Without allocating resources to training and onboarding, Maintenance 4.0 will be stuck in the planning phase.

7. Share risk with external vendors. Industrial players are unable to keep up with the rapid pace of change. Fortunately, OEMs and other service providers are finding ways to address market opportunities and overcome challenges to their own underlying businesses. Industrial plants should spend the time understanding the strategic road map of their most important OEM suppliers and consider mutually beneficial ways to align investments and plans.

Setting your strategy

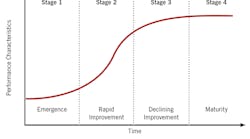

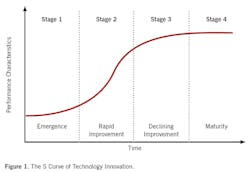

In Figure 1, the S curve of technology innovation is applied to the Maintenance 4.0 strategy. The S curve refers to the stages of a new technology’s performance as it matures. In the first phase, it evolves slowly. After a breakthrough occurs, performance improves rapidly. Next, the pace of improvement declines. Finally, with maturation, greater performance is difficult to achieve.

It should be noted that the S curve is not an exact model, and not all technologies follow the curve. Given the pace of innovation, even if Maintenance 4.0 follows the S curve, there is no way of knowing the duration of Rapid Improvement 4.0 (Stage 2). One can look back at this period as merely the beginning of emergence, attributable to new areas of innovation in the data-science discipline – specifically automated machine learning.

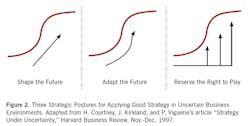

Three strategic postures for applying good strategy in uncertain business environments are articulated in the HBR article “Strategy Under Uncertainty” (see Figure 2):

- Shape the Future – Shapers are organizations that drive their industry toward new structures.

- Adapt to the Future – Adapters choose where and how to compete within the given structure.

- Reserve the Right to Play – Organizations invest incrementally to “stay in the game” without committing to new strategies.

These models also can be applied to plants adopting Maintenance 4.0 practices. Let’s review each.

Reserve the right to play. With this approach, industrial players build intelligence around new solution offerings without altering current practices. Although this option seems to be the safest approach, it may be the riskiest. Plants that wait and expect to catch up at a later date may miss the financial and competitive advantages of adopting Maintenance 4.0. Sometimes, strategic patience is a virtue; other times, it is a mistake.

Eitan Vesely is a co-founder and CEO of Presenso, and Deddy Lavid (Ben lulu) is a co-founder, CTO, and VP of data science at Presenso. They co-authored the Maintenance 4.0 Implementation Handbook, from which this article was excerpted. The book will be available this fall at www.mro-zone.com.

Shape the future. Similarly, there is an obvious downside for industrial plants that pursue “shape the future.” Industrial plants that have built their own internal machine learning capabilities fit into this category. It requires significant investment in recruiting big data scientists and building out Maintenance 4.0 competencies. At the same time, the level of investment and risk may not justify the potential reward, especially because newer solutions may provide the same value at a lower cost.

Adapt to the future. This approach is the middle path for industrial plants. These organizations recognize the uncertainty associated with disruptive technologies and position themselves to react when opportunities emerge. Of equal importance is how to fit this Maintenance 4.0 into existing processes.

Conclusion

How is this relevant for Maintenance 4.0? With Maintenance 4.0 in its infancy, industrial plants may be tempted to wait on the sidelines until solution winners and losers can be easily identified. This is a bad idea. The average industrial plant misses 17 days in production every year, costing billions of dollars in lost revenue. If the cost of downtime for one minute of production in the automotive industry can reach $50,000, the risk of not pursuing Maintenance 4.0 is far greater than the risk of waiting.