Push the needle: How 6 companies are achieving predictive maintenance success

When it comes to reliability best practices, learning from the practical experience of peers is the next best thing to trialing all the options yourself. With the myriad of predictive maintenance (PdM) solutions available and diversity of potential use cases, every asset-intensive company has its own preferences, priorities, timelines, and budgets for tackling unplanned downtime. To help communicate real-world successes and uncover the possibilities, we chose six case studies to spotlight in this article.

The PdM stories range from deploying modern PdM essentials to results from comprehensive, advanced programs. Some include elements of prescriptive maintenance (RxM), whether future intentions or already-established internet of things (IIoT) enablers. These technologies, such as online, real-time condition monitoring, artificial intelligence (AI), machine learning (ML), advanced analytics, and cloud platforms, help to automate predictions of asset failure and provide the foundation for recommending prescribed corrective actions.

Here we present highlights from companies benefitting from PdM, including example successes, why they matter, and the chosen tools and methods.

- U.S. industrial products manufacturer

- Tennessee snack food manufacturer

- Louisiana alumina refinery

- San Diego energy utility

- Singapore rail operator

- Australian iron ore mine

U.S. industrial products manufacturer

Achievements: PdM saves millions of dollars in unplanned downtime and Mike Macsisak, a maintenance veteran, has seen it happen throughout his career. In his current role setting up a PdM program for a U.S. manufacturer of industrial products, steam trap problems such as boiler steam pipeline flaking are being caught and corrected early, and his team is consistently putting the right oil in the right machines. A mine he previously worked at had 91% uptime because of PdM. And he recently heard that a bearing solution he implemented seven years ago for a food manufacturer solved the root cause of a recurring problem and is still running “like new” today.

Why it matters: Manufacturers depend on asset reliability and efficiency, but Macsisak’s current plant lacked a structured PdM program and modern tools. “I teach that if you do PdM and you do it right, and you do it consistently, then you can avoid breakdowns that would otherwise take away production,” he explains. “It is always better to schedule and plan than to fight fires.”

Approach taken: His first focus was revamping the plant’s lubrication program, including switching to Oil Safe containers from OilSafeSystem, throwing out old single-use oil containers, instructing that everything gets filtered, and affixing color-coded labels on the buckets and machines so it is clear what type of oil is used and where. He’ll soon do the same for grease and he is getting ready to begin oil analysis.

For the approximately 600 steam traps on-site, he is teaching his team how to use ultrasound guns from UE Systems and thermal imaging cameras from FLIR Systems to monitor for problems. He also uses an ultrasound gun to test the electrical panels every three months, and he plans to show the team how to monitor the panels after he completes an audit of all the panels and wiring.

The company is also looking into doing RxM, but in the meantime, the industry veteran’s maintenance prescriptions are inherent from personal experience. “I’ve learned over the years how to figure out problems in order to ‘fix it forever,’ because that’s the whole goal.”

Tennessee snack food manufacturer

Achievements: Year-to-date equipment downtime is 0.75% and unplanned downtime is 2.88% at PepsiCo’s Fayetteville, TN, Frito-Lay plant, said Carlos Calloway, the site’s reliability engineering manager, in his presentation at the Leading Reliability 2021 conference.

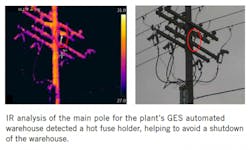

Vibration readings confirmed by ultrasound helped to prevent a PC combustion blower motor from failing and shutting down the whole potato chip department. IR analysis of the main pole for the plant’s GES automated warehouse detected a hot fuse holder, helping to avoid a shutdown of the entire warehouse. Increased acid levels were detected in oil samples from a baked extruder gearbox, indicating oil degradation, which enabled prevention of a shutdown of Cheetos Puffs production. Ultrasound analysis findings led to a Fritos quill replacement, avoiding downtime, lost sales, and extra sanitation steps.

Why it matters: The Frito-Lay plant produces upwards of 150 million pounds of product per year, including Lays, Ruffles, Cheetos, Doritos, Fritos, and Tostitos. Its robust program of PdM technologies and services enables real-time assessment of equipment health to predict failures or its remaining lifespan.

Approach taken: Vibration analysis is used on mechanical applications. The top 50 critical assets were chosen for remote vibration monitoring and a third-party company helps to analyze that data and send alerts to the plant for investigation and resolution. Another service partner does quarterly vibration routes on selected equipment. Infrared is used on electrical equipment, some rotating equipment, and heat exchangers. Quarterly IR analysis is performed in-house on all motor control center rooms and electrical panels.

In addition, the plant has done ultrasonic monitoring for more than 15 years, and it is “kind of like the pride and joy of our site from a predictive standpoint,” said Calloway.

Several UE Systems products are used, including the Ultraprobe 15,000 for most route-based PdM, Grease Caddy for any greasing, Remote Access Sensor (RAS) boxes on cooling tower fans, 4Cast systems on compressors for continuous monitoring, the OnTrak remote lubrication system, and Ultratrend DMS software.

Calloway made certain to acknowledge the role of PdM Tech Roy Smithson’s expertise: “Without Roy, this program wouldn’t be anywhere near as successful as it is now, and I am very lucky to have him on our team.”

Louisiana alumina refinery

Achievements: The Noranda Alumina plant in Gramercy, LA, realized a 60% decline in bearing changes in the second year of using a new lubrication solution, saving approximately $900,000 in bearing purchases and avoiding costly downtime. “Four hours of downtime is about $1 million dollars’ worth of lost production,” said Russell Goodwin, a reliability engineer and millwright instructor at Noranda Alumina in his Leading Reliability 2021 presentation. In addition, the grease completion rate reached 92% this year.

Why it matters: Quite simply, the refinery is the only USA-based alumina plant operating. “If we shut down, you’ll need to import it,” explained Goodwin. The plant has pervasive dust, dirt, and caustic, complicating reliability and maintenance efforts.

Approach taken: Noranda Alumina tracks all motors and gearboxes 1,500 rpm and higher with vibration readings and most below 1,500 with ultrasound. Ultrasonic PdM was introduced to the plant after Goodwin joined the company in 2019. At that time, the grease completion rate was 67%. “If grease was not visibly coming out of the seal, the mechanical supervisor did not count the round as complete,” he explained. “The 401 Digital Grease Caddy was an easy sell for me because it would help us put in the right amount of grease, know that it was greased, and prove it with data on the date, time, and quantity greased.” Completion rates subsequently increased to 81% in 2020 and 92% in 2021 to date.

The team’s first project with the 401 was on a wet cake loadout gator belt whose bearings kept going out because of contamination. “Tool-enabled tracking helped to prove that it wasn’t improper greasing, but rather the bearing was made improperly. So, this 401 can do a little more than just grease—it helped us find the root cause,” said Goodwin.

His current goal is to reduce hand greasing and time-based greasing with OnTrak Single Point Lubricators. He is installing new grease blocks and installing OnTrak onto each bearing in a pilot program.

San Diego energy utility

Achievements: San Diego Gas & Electric (SDG&E) Company is actively exploring a variety of AI, ML, and emerging technology opportunities to improve operations and maintenance. In one example, previously unleveraged data applied to ML algorithms predicted the failure of T-splices, a crucial underground power distribution asset, with a high degree of accuracy and sufficient time for crews to plan repairs. Due to its success, the program is being extended to other critical assets such as oil switches, load break elbows, and transformers.

Another initiative incorporates AI/ML and computer vision to automatically detect assets and damages on the utility’s electric system to better plan maintenance and help reduce the risk of wildfire. Millions of equipment inspection images captured by drones in the field are ingested and analyzed by trained ML models to identify and prioritize damaged assets.

Why it matters: Underground assets, which make up more than 60% of SDG&E’s total distribution grid, are approaching more than 40 years in age and require advanced maintenance approaches to avoid unplanned downtime. T-splice failures can trigger outages that impact customers’ lives and can cost tens of thousands of dollars to resolve. Additionally, considering California wildfires increased in size by roughly 800% in the last 50 years, it is critically important to improve situational awareness and maintenance of above-ground equipment and vegetation assets.

Approach taken: The T-splice initiative uses iPredict for electricity distribution, a solution co-developed by SDG&E, PA Consulting, and Toumetis, and available through PA Consulting. Granular high-frequency sub-cycle data is correlated with other system data, allowing algorithms to recognize and interpret anomalies and emerging signs of asset failure in near real time. In addition to underground assets, SDG&E also expects to use the solution to predict overhead equipment failures.

The utility’s computer vision initiative leverages its Drone Investigation, Assessment, and Repair Program (DIAR) and Intelligent Image Processing (IIP) architecture. “Through AWS (Amazon Web Services) and using services like SageMaker, we can now detect over 40 unique asset and damage conditions in imagery,” said Gabe Mika, the digital strategy, cloud, and innovation lead at SDG&E, in his AWS for Industrial Web Day 2021 presentation. “Now, we are exploring emerging technologies paired with existing technologies like LIDAR to become more precise, prescriptive, and efficient about how we manage vegetation,” he added.

Singapore rail operator

Achievements: A significant goal was met in August 2019 for Singapore rail operator SMRT Trains Ltd. when it achieved one million mean kilometers between failure (MKBF) across all its lines. This is the equivalent of traveling over the entire network thousands of times before seeing a service delay of five minutes or more. Hundreds of manual planning hours have been eliminated, and about 20 maintenance train deployments per year are avoided. Engineers have a better idea of the work conditions and the work crews’ maximum work capacity per shift is optimized.

Why it matters: The company operates and maintains more than 282 kilometers of rail track and its average daily ridership in 2020 was more than 2 million people. It previously relied on manual maintenance planning methods that used tens of millions of data points per year across separate data silos. A new means was needed to assess the whole network’s asset condition holistically and automate prioritization recommendations to improve safety, reliability, and convenience to SMRT’s commuters, and to keep the tracks in good condition to avoid service delays.

Approach taken: SMRT Trains implemented a Predictive Decision Support System (PDSS) based on AssetWise Linear Analytics from Bentley Systems. “PDSS aims to create a data repository designed specifically for us to centralize all the data completely and accurately, as well as a data analytics engine that can analyze the data for maintenance strategy recommendations, resource optimization, and improved maintenance effectiveness,” says Jessie Nguyen, senior engineer at SMRT Trains Ltd.

SMRT Trains plans to continuously improve its maintenance efficiency and effectiveness. “All we want is for our tracks to be in good condition so that our commuters can travel safely and smoothly every year, every day,” adds Nguyen.

Iron ore mine

Achievements: AI-driven PdM and condition monitoring enabled an iron ore mine in Australia to avoid a substantial amount of unnecessary spend. Algorithms developed by Metso, a mining equipment manufacturer, monitor the mine’s drive and hydraulic system sensor data for failure patterns and detected the anomaly in a specific area of a crusher. Metso’s services team alerted the on-site maintenance team to evaluate the condition, and a loosened structure was found and easily secured. “Had this not been flagged and fixed, it had the potential to cause a catastrophic event with potential costs of more than $1 million, says Jani Puroranta, chief digital officer at Metso.

Why it matters: Mineral processing plants and their equipment and technology providers work relentlessly to avoid incidents and associated maintenance and downtime costs. Demanding conditions and around-the-clock operation make this goal especially challenging.

Approach taken: The mine is piloting Metso Metrics for Mining, a digital service from Metso built on an IIoT platform from Rockwell Automation. It pulls customer equipment data into a digital twin in the cloud for analysis, and Metso Performance Center experts provide remote support and optimization services. Metso reports that more than 10 mines worldwide are already using the solution and have connected more than 1,000 pieces of IIoT equipment. In addition to helping customers improve production and reduce risk, the data is also used by Metso engineers to monitor new equipment designs and create smarter and more efficient equipment. “AI is not enough. We also need human intelligence,” notes Puroranta.

Lessons learned

Maintenance veteran Macsisak acknowledges that starting up PdM is no easy task. “You’ve got to sell it to management and show them the value of it so they will get onboard,” he says. “Showing the value requires trending and tracking, over and over and over. It does get boring until you find something wrong. That’s the only way you can make it work.”

But as these six case studies demonstrate, predicting and preventing failure with proactively applied corrective actions is highly effective at improving uptime, increasing efficiency, controlling costs, and improving performance.

It is why PdM is firmly a reliability best practice now, and RxM will only make it stronger.

This story originally appeared in the October 2021 issue of Plant Services. Subscribe to Plant Services here.

About the Author

Sheila Kennedy

CMRP

Sheila Kennedy, CMRP, is a professional freelance writer specializing in industrial and technical topics. She established Additive Communications in 2003 to serve software, technology, and service providers in industries such as manufacturing and utilities, and became a contributing editor and Technology Toolbox columnist for Plant Services in 2004. Prior to Additive Communications, she had 11 years of experience implementing industrial information systems. Kennedy earned her B.S. at Purdue University and her MBA at the University of Phoenix. She can be reached at [email protected] or www.linkedin.com/in/kennedysheila.