The infrared camera: The new predictive maintenance inspection tool

Significant changes have occurred in the commercial infrared camera industry as a result of declassified military thermal sensor development that took place in the 1980s. Before then, most high-performance infrared cameras used photon-detection sensors that needed to be cooled with liquid nitrogen. These developments gave the maintenance technician a new inspection tool: the infrared camera.

The wavelength of infrared radiation is longer than that of visible light, but shorter than microwaves. See Figure 1. Infrared radiation can be felt but not seen. Every object emits infrared radiation. The intensity depends on the temperature and a material surface property called emissivity. Infrared cameras sense the infrared energy an object emits and replicates it as a surreal image where hot areas appear bright and cold areas appear dark.

Figure 1. Infrared radiation has a wavelength longer than that of visible light.

Using the infrared camera as a predictive maintenance tool solves maintenance problems, controls manufacturing costs and improves plant safety. Anything that moves or uses energy can be viewed with an infrared camera. Infrared inspection can identify problem areas early, which prevents costly downtime or personal injury.

The complexities of earlier infrared cameras were a significant barrier to widespread use for predictive maintenance. Cooling the detectors to a very low temperature required about 10 minutes. The thermal sensors in modern high-performance cameras eliminate the need for cryogenic cooling and offer a turn-on time of 15 seconds or less.

Advances in electronics yielded smaller, more reliable and less expensive cameras. The lower price of these units enables even small manufacturing firms to incorporate infrared scanning into their arsenal of predictive maintenance tools.

Thermal sensors

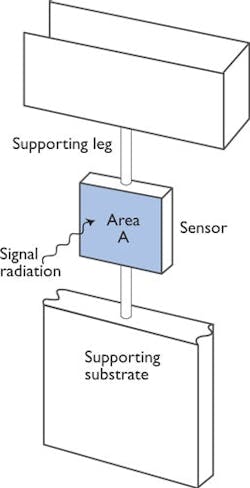

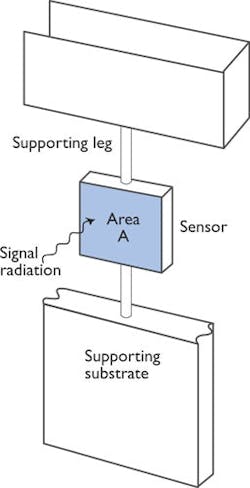

The principle of a thermal infrared sensor is shown in Figure 2. A tiny, thin platesometimes called a plateletis fabricated on a silicon chip. The platelet is 50 microns square by 0.5 micron thick. Even smaller sizes are under development. Long thin support legs and a surrounding vacuum isolate it from the substrate. Focusing low-level thermal radiation from a target onto the platelet heats it. The higher the target temperature, the greater the focused radiation and the higher the platelet temperature, which is measured by the change in resistance of a resistor deposited on the plate. This is the basis for the microbolometer sensor.

Figure 2. The principle of a thermal infrared sensor.

The temperature also can be measured by a thermocouple with the hot junction on the plate and the reference junction on the substrate. This is the basis for the thermoelectric sensor. Temperature also can be measured by an electrical capacitance effectthe basis for the pyroelectric sensor.

Microbolometer technology

Individual sensor elements measure the change in electrical resistance of a vanadium oxide resistor deposited on the platelets. Incoming target radiation heats the vanadium oxide, causing a change in electrical resistance, which is read by measuring the resulting change in bias current.

The two-dimensional array on the platelet can have 80,000 sensors or more. The camera's refresh rate of 30 Hz produces an image similar to what's seen in a video.

Most cameras feature the 320 by 240 microbolometer array. However, the 160 by 120 array is an alternative for many applications. The smaller array and its camera can be produced at a lower cost, providing an opportunity for cost-sensitive purchasers to implement this technology.

The advantage of the larger array is its field of view. For a given f-stop and lens configuration, the 320 by 240 array will have identical spatial resolution as the 160 by 120 array. But the target size will be twice as large in both dimensions for the camera with the larger array. For some commercial applications, the cost savings of the smaller array may overshadow this shortcoming.

Thermoelectric technology

In the thermoelectric sensor, individual thermocouples measure the temperature of the platelet. Each platelet can carry as many as five series-connected thermocouples that produce a small voltage in response to focused radiation from the target. Moving the sensor array in the focal plane of the camera lens produces a two-dimensional image consisting of 14,400 pixels (120 by 120).

A silicon nitride pattern deposited on the silicon produces a thermally isolating bridge structure with selectively etched well pits in the silicon wafer under the bridge structure. Dissimilar metals A and B are deposited on the bridge structure. Electrical contacts are added along the sensor. Each element has three series thermocouples. Because this array is linear, the electrical connections can be located to the side, permitting a large fill factor.

Advances in infrared technology reduce infrared camera complexity and price, which produces more widespread applications for the technology. Infrared cameras are an integral part of predictive maintenance inspection at large companies, and small- to medium-size companies are embracing it, as well.

Roger Schmidt is the founder of Infrared Solutions, Inc. He can be reached at [email protected], (763) 551-0003 or (800) 760-4523.