Case study: Inside Perdue Farms’ award-winning maintenance culture transformation

Key takeaways

- The team at the Perdue Farms Concord, NC facility were the sole 2025 winner of the Reliability of Everything™ Culture Improvement Awards

- A structured maintenance and reliability roadmap helps align maintenance goals with long-term operational reliability and plant-wide performance.

- Predictive maintenance tools like vibration analysis cut downtime and enhance decision-making with real-time equipment insights.

- Sustainable upgrades—like energy-efficient systems—can lower costs while advancing corporate environmental goals.

- Team engagement and recognition programs drive cultural change and continuous improvement in plant operations.

The Reliability of Everything™ Culture Improvement Awards are a way to recognize people from real-world plant environments who have worked hard to make a difference in improving culture and operations.

The award can be earned in three categories – Best Culture Innovation (unique solution to improve culture), Best Culture Startup (improving a challenging culture/difficult situation), and Best Sustaining Culture (evidence of a sustainable top-quartile environment). Regardless of category, all three awards are based on improvement of reliability & maintenance metrics results (25%), documented journey of improvement/process used with lessons learned (25%), and improvement in culture (50%).

The sole 2025 award was earned by Perdue Farms in Concord, North Carolina in the category Best Sustaining Culture, through the leadership of Perdue Maintenance Manager Charlie Hogan. In a unique achievement, this same facility won the Best Culture Startup Award one year earlier through the leadership of Gilberto Carrera (now Sr. Director of Maintenance Reliability for Perdue Farms Food Organization). Winning this award for a second year in a row is a testament to the dedication and commitment Perdue has toward Maintenance and Reliability Excellence. The Concord Plant was their pilot plant and after 4 years continues to lead these efforts and set the bar across the Perdue Foods Division.

The awards are presented to winners at the March annual MARCON (Maintenance and Reliability Conference) put on by the Reliability and Maintainability Center (RMC) and held at the Knoxville Convention Center, adjacent to the University of Tennessee. This article is based on that submission, their presentation and some of my comments.

Case study: How Perdue Farms built a culture of maintenance and reliability excellence

Perdue Foods, a 105-year-old family-owned business, operates 124 facilities and employs over 20,000 associates, including nearly 10,000 farmers (see Figure 1). The company’s vision is to become the most trusted name in food and agricultural products by focusing on operational excellence through improved downtime, cost efficiencies, and sustainability.

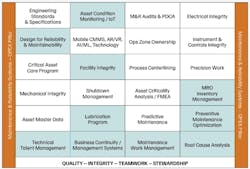

From Gilberto Carrera’s submission last year, the Perdue Foods team was well on their way through the reliability journey and working on the mid- to long-term strategies. As they worked on identifying the fundamental initiatives that they needed to focus on, multiple sources were used to put together their internal maintenance & reliability system (MRS) framework. Figure 2 shows the Perdue team’s 10 key items of focus.

Charlie Hogan outlined a comprehensive overview of the company's maintenance strategies and initiatives aimed at enhancing operational efficiency and reliability. Hogan emphasized the importance of developing a maintenance and reliability culture that prioritizes asset longevity and optimal labor utilization. Key projects included significant upgrades to hydraulic systems, air compressor systems, steam management, and vacuum technologies, all of which contribute to energy savings and improved operational performance.

Hogan also credited the implementation of predictive maintenance technologies and standardized processes for lubrication and inventory management to further enhancing reliability and reducing costs. The maintenance and reliability team’s recognition for their achievements underscores the effectiveness of these initiatives.

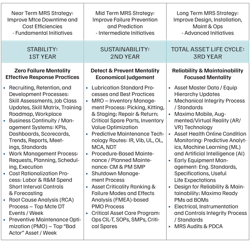

With their MRS framework defined, Hogan and the Perdue team developed a strategic Maintenance & Reliability (M&R) roadmap to layout a 1-3 year implementation plan. Six strategic initiatives were identified as fundamentals for the Near-Term Strategy (1st year). They also identified tentative initiatives for the Mid-Term (2nd year) and Long-Term (3rd year) phases of their implementation roadmap. Figure 3 shows the Perdue team M&R Roadmap with initiatives initially selected for each phase of their strategic implementation phases.

Since early 2024, Hogan took over the maintenance manager role and started filling up their empty seats/putting key players in positions. Each quarter, they have a team meeting, where all 50 of the Perdue M&R team members get together to go over successes and failures from previous quarters, and then review where they are going over the next 3 to 6 months.

The phases of team development follows the Forming-Storming-Norming-Performing-Adjourning model from Bruce Tuckman. Once fully staffed, it allows more flexibility to correct bad practices through process improvement plans and start building the professional workmanship into everyday practices. At every opportunity, Hogan coaches hourly, salary, M&R, Ops and Sanitation team members, to emphasize expectations for the M&R team to be the best at everything they do, including leading by example for all Perdue associates.

Year over year, they have gotten exponentially better, but like for most, it’s still a journey to M&R excellence. The Perdue M&R team is sitting around 4.5% mechanical downtime YTD, with a target of 3.8%, and have three capital projects dedicated to helping them reduce/eliminate their top 3 bad actors which accounts for ~2% of the mechanical downtime YTD. Since 2020, they have reduced downtime from 10.4% (FY21) to 7.2% (FY 23) to 4.8% (FY25 at the time the graph was created for MARCON), resulting in a 54% reduction and sustaining around their 4% company target. (Note: The target for each plant starting FY24 was a 5% reduction over previous year. Therefore, the target for FY25 at the Concord plant is 3.8%.)

Hogan and the Perdue M&R team (see Figure 4) have been able to get some of their key hourly associates involved in correcting some of their top bad actors and recognized them for their successes. This has changed the dynamic for their team, for all associates to see/hear about process improvements and recognizing the efforts, and has increased employee engagement bringing their ideas and suggestions to the table.

There are many individual success stories. Just one example is from M&R lead associate, Brent Chapman, who corrected a belt failure mode and DT reduction that resulted in an annual product improvement of >1M lb. He received the excellence award for the Concord site, one of two awards given each year.

Award-winning culture: Key highlights from Perdue’s reliability and maintenance excellence submission

Mission: To provide innovative food and agricultural products that enhance the quality of life for everyone we touch. We believe in responsible food and agriculture®

Vision: To be the most trusted name in food and agricultural products.

Values: Quality, Integrity, Teamwork and Stewardship

Perdue Farms’ facility in Concord, North Carolina, is committed to implementing maintenance best practices that emphasize sustainability and rigorous root cause analysis. As one of the leaders in the agricultural industry, Perdue Farms recognizes the critical importance of efficient maintenance strategies in enhancing operational reliability while minimizing environmental impact.

The facility’s maintenance program is centered on preventive and predictive maintenance methodologies, aiming to reduce equipment failures and downtime. By employing condition monitoring technologies and data analytics, Perdue Farms can make informed decisions based on real-time performance data, ensuring that maintenance efforts are timely and effective. These practices not only extend the lifespan of critical equipment but also diminish resource consumption and waste, aligning with the company’s sustainability goals.

A cornerstone of Perdue Farms' approach is the rigorous application of true root cause analysis (RCA). This methodology goes beyond traditional failure analysis, focusing on identifying and addressing the underlying causes of equipment failures rather than just the symptoms. By implementing RCA, the facility can develop targeted maintenance strategies that eradicate recurring issues and enhance overall operational efficiency.

Furthermore, Perdue Farms is dedicated to fostering a culture of sustainability within its maintenance operations. This includes integrating environmentally friendly practices, such as using energy-efficient technologies and sustainable materials, in maintenance activities. By prioritizing these initiatives, the facility not only reduces its carbon footprint but also sets a benchmark for industry-wide sustainability efforts.

Summary of select key insights:

- Legacy of trust and quality: Perdue Foods' longstanding history of over 100 years highlights its established reputation in the industry. This legacy not only fosters customer loyalty but also attracts partnerships with farmers and suppliers who value trustworthiness and reliability. The company’s commitment to maintaining high standards is evident in its operational practices and community engagement, reinforcing its brand as a leader in the food sector.

- Strategic roadmap for reliability: The MRS framework, which focuses on strategic pillars and initiatives, is a clear representation of how Perdue Foods plans to enhance its operational capabilities. By concentrating on reliability as a core business strategy, the company ensures a proactive approach to maintenance that is aligned with its long-term vision. The structured roadmap allows for measurable improvements in asset management, which is crucial for sustaining high levels of productivity.

- Environmental responsibility: Perdue Foods is not only focused on operational efficiency but also on sustainability. Initiatives such as upgrading to energy-efficient compressors demonstrate the company's commitment to minimizing its environmental impact. These efforts not only reduce operational costs but also position the company as a responsible corporate citizen in the eyes of consumers increasingly concerned about sustainability.

- Data-Driven Decision Making: The implementation of predictive maintenance technologies, such as oil sampling and vibration analysis, represents a significant shift towards data-driven decision-making in maintenance practices. By leveraging technology, Perdue Foods can anticipate potential failures before they occur, which minimizes downtime and enhances overall operational efficiency. This proactive maintenance approach is indicative of modern practices in the manufacturing and food production sectors.

- Training and succession planning: Hogan’s emphasis on training and building a professional culture is vital for sustaining the operational excellence of Perdue Foods. By investing in the professional development of team members and emphasizing succession planning, the company ensures that it maintains a skilled workforce capable of adapting to future challenges. This cultural investment contributes to employee satisfaction and retention, which are essential for long-term success.

- Cost savings and efficiency: The successful reduction of costs—from $25,000 to $2,000 for pump replacements—illustrates the effectiveness of the maintenance initiatives implemented by Hogan’s team. Such significant cost savings not only enhance the company’s bottom line but also reinforce the value of in-house maintenance capabilities. By reducing reliance on external contractors, Perdue Foods can allocate resources more efficiently.

- Recognition and awards: The achievements of the maintenance and reliability team, recognized through several awards, highlight the effectiveness of the company’s initiatives. These accolades not only boost morale but also serve as a benchmark for other teams within the organization. Recognition fosters a culture of excellence and encourages continuous improvement, which is vital in today’s competitive landscape.

In conclusion, Perdue Farms’ Concord facility demonstrates that by embracing sustainable maintenance practices and a root cause analysis approach, organizations can achieve both operational excellence and environmental responsibility. This proactive strategy ultimately supports the company’s core values of Quality, Integrity, Teamwork and Stewardship.

Is your team an award winner?

Nominations are currently open for the 2026 Reliability of Everything™ Culture Improvement Awards!

Sponsored by Plant Services magazine and the University of Tennessee Reliability & Maintainability Center, these awards are about making measurable progress, regardless of where your company starts or where it is now.

Sharing details of your company’s journey — what worked and, just as important, what didn’t and why — can be of great value to all plant professionals.

Plants can apply in three different categories:

- Best Culture Start-Up

- Best Culture Innovation

- Best Sustaining Culture

Apply at: https://rmc.utk.edu/the-reliability-of-everything-culture-improvement-awards-submission-form-awards/

Submissions must be received by October 31, 2025.

2024 award winners

- Best Culture Start-Up: Y-12 National Security Complex Infrastructure, Missions Systems & Integration, Oak Ridge TN

- Best Culture Start-Up: International Flavors & Fragrances (IFF), Memphis TN

- Best Culture Start-Up: Perdue Farms, Concord NC Facility

- Best Culture Innovation: Renaissance Reliability LLC / Medalcraft Mint LLC, Green Bay WI

About the Author

Klaus Blache

UT-RMC

Dr. Klaus Blache is research professor, industrial and systems engineering, and director of the Reliability and Maintainability Center, University of Tennessee College of Engineering in Knoxville. He was chairman of the Society of Maintenance & Reliability Professionals from 1997 to 1999, when he was manager of manufacturing reliability and maintenance at General Motors. He can be contacted at [email protected].

Charles Hogan IV

Charles (Charlie) Hogan IV is Maintenance Manager at Perdue Farms in Concord, North Carolina.