Plan-it fitness: The great value of maintenance planning

Maintenance planning gives a maintenance workforce a massive advantage in trying to increase company profit. Planning maintenance work helps plants keep assets running reliably because performing more-proactive activities can let plants avoid having to do reactive work to restore lost production.

[sidebar id="5"]

The mission of maintenance is to maintain reliable operation. Proper maintenance is not about letting assets fail and then having to restore them to service. (That wouldn’t be “maintaining,” would it?) Yet, many good plants perform a significant amount of such reactive maintenance. Nevertheless, the good plants that strive to be great plants and that understand the true mission of maintenance ask, “How can we turn the corner and do even more proactive work when we have our hands full with reactive work?” Maintenance planning answers this question by leveraging an understanding of maintenance wrench time.

So-called wrench time is the percentage of time that craftspeople move jobs ahead out of the total time they are available to work. First, take out vacation, training, and similar circumstances that make persons simply not available to work. Then consider the time they are on-site and available to a supervisor for work assignment. Next, for moving jobs ahead, think of a craftsperson at a job site turning a wrench. The person moves the job ahead. However, if that person stops work to walk to the storeroom and return with a spare part, the job momentarily stops moving ahead. So the time obtaining the part counts as a delay and not wrench time even though the person is obviously “working.” Consider as delays such circumstances as morning check-in meetings, obtaining new assignments, walking to or from jobs, obtaining parts or tools, asking for help, breaks, putting away tools at the end of the day, and most travel. They are delays because although these activities make up part of a normal craft day and are certainly a cost of doing business, jobs do not move ahead during these times. On the other hand, consider as wrench time most circumstances of persons actively doing just about anything to a piece of equipment at a job site or in the shop and also include troubleshooting for unclear job scopes, LOTO involvement (although not waiting on others), confined-space attending, and even filling out job paperwork before, during, and after jobs.

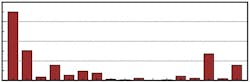

With this conceptual definition of wrench time, it surprises most people that wrench time for good plants with good maintenance forces with everybody busy is only about 35%. See Figure 1. That is, crafts average only about 3½ hours out a10-hour shift productively moving jobs ahead out of the time they are available to do work. They average about 6½ hours (65% of their time) in other activities, not actively moving jobs ahead.

[sidebar id="4"]

Furthermore, it's notable that these good plants are at 35% wrench time across industries and cultures worldwide. Why is everyone at the same percentage? It is because at 35% wrench time, crafts “feel busy” and plants have “right-sized” their maintenance staff over the years to take care of operations (i.e., do reactive work). Over time, when operators report an increasing number of problems, causing the work backlog to grow, a plant hires additional maintenance staff. Yet also over time, when maintenance persons leave or retire, the plant does not immediately replace them if the backlog is not growing. Consequently, plants essentially size their workforce to be good at doing reactive maintenance.

This low wrench time presents a great opportunity because proper planning (and scheduling) can improve a maintenance force to 55% wrench time. So the merely good plant has an inherent capacity to do more proactive work. Best practice wrench time is 55% (not 80% as some might think), a level easily achieved and sustained. Improving from 35% wrench time to 55% wrench time might not seem like a huge gain, but the gain is much more than the apparent 20%. The gain is a 57% improvement (55/35=1.57). This means that a 30-person would be performing the work of a 47-person workforce (30 x 1.57 = 47). Thus, the workforce of 30 persons gains an extra 17 persons “for free” to do extra work. Of most importance, any extra work is proactive work because the workforce has already been “sized” to handle all the reactive work!

Consider the financial leverage of such planning by using $50 per hour for a loaded (including benefits) craft wage. (Many person use $100 per hour). The extra 17 persons are worth $1.8 million in labor alone (17 persons x 2,080 hours per year x $50 per hour). Furthermore, the industry rule of thumb that says that every $1 invested in extra proactive work contributes $10 to company profit means that proactive maintenance heads off more-expensive reactive work, but of more importance, it also increases reliable plant capacity. Thus, a single planner who helps increase wrench time for 30 persons makes an $18 million (10 x $1.8 million) profit contribution.

Far-fetched? The hard-to-believe concept that most good maintenance workforces operate at only 35% wrench time means there exists an untapped source of extra labor for proactive maintenance. Merely good plants can turn the corner to reduce reactive maintenance beyond “normal” levels to become great plants with proper planning and scheduling.

About the Author

Doc Palmer

PE, MBA, CMRP

Doc Palmer, PE (Ret.), MBA, CMRP is the author of McGraw-Hill’s Maintenance Planning and Scheduling Handbook and as managing partner of Richard Palmer and Associates helps companies worldwide with planning and scheduling success. For more information including online help and currently scheduled public workshops, visit www.palmerplanning.com or email Doc at [email protected]. Also visit and subscribe to www.YouTube.com/@docpalmerplanning.