Why failure is not an option for walkaround inspection programs

Key Highlights

- Walkaround inspections serve as a vital first line of defense, detecting issues that automated systems may overlook.

- Transitioning from paper-based to digital data collection enhances accuracy, accountability, and the ability to analyze historical equipment condition information.

- Effective programs require ongoing support from plant management and executives to allocate resources and foster a safety culture.

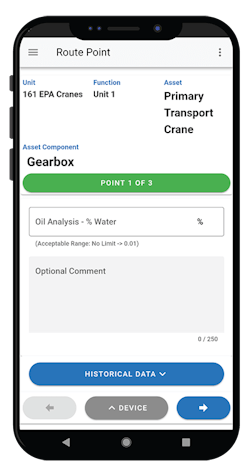

- Modern tools like handheld devices and automated exception reports streamline inspections.

- Building a reliability-focused culture involves integrating walkaround findings with condition monitoring data, promoting teamwork, and demonstrating cost savings to leadership.

Plant professionals largely agree that walkaround inspection programs are crucial to reliability success, even with remote and automated condition monitoring options growing. Walkaround programs achieve unique, indispensable objectives: using human senses to detect machine anomalies and safety issues and integrating these observations with condition monitoring findings to improve work order prioritization.

Walkaround inspections are ultimately intended to prevent production interruption, as production losses can far outweigh the cost of equipment repair. And yet, it is not uncommon for walkaround inspection programs either to fail or to never fully get off the ground. A surprise failure, or even an anticipated failure, of a critical asset may leave a facility unable to overcome the consequences. Sadly, the highest potential cost is the loss of life.

The first-hand plant insights described in this two-part article are shared to help you establish a successful, enduring walkaround inspection program.

- This article, Part 1, explores why physically monitoring critical assets remains a vital reliability practice that necessitates consistent plant and executive support.

- Part 2 outlines common challenges to setting up, conducting, and sustaining walkaround inspection programs, and offer actionable best practices to ensure your program is optimized to withstand the test of time.

Why are walkaround inspections still relevant?

Industrial machines are improving but are not immune to failure. Rarely is process equipment maintenance-free, and even properly designed systems may not be able to withstand careless cleanings, poor operation practices, or deficient installation or repairs.

Likewise, despite advancements in asset condition monitoring (e.g., oil analysis, ultrasound, vibration analysis, thermography, and remote monitoring sensors), the newer technologies may only give an indication of a developing problem or change in condition. Some elaborate systems allow for detailed problem analysis, but often field analysis is necessary.

Importantly, the belief that failures can’t get past this “first line of defense” is frequently incorrect and challenged by walkaround inspections. Some severe problems give no indication of impending failure by tribology, heat, or vibration. As an example, bearing housing lip seals eventually begin to leak, resulting in lower than designed oil levels. Diminishing oil levels may not be recognized without monitoring and trending by routine visual inspection.

Visual inspections also commonly bring to light issues that are overlooked by other condition assessment techniques. For instance, until a lack of cooling begins to have a detrimental effect on the components of a motor, such as elevated PeakVue or Spike Energy, the problem of plugged fins is often undocumented. Safety issues such as loose coupling guards and exposed wiring are another example. Any such “housekeeping” issues have a negative impact on equipment reliability should be included in a walkaround inspection program.

Modern tools maximize the program’s value

Numerous challenges and dynamics affect whether and how walkaround inspection programs are set up and funded; the degree of success realized; and whether the programs can be sustained over the long haul.

Plants lacking a structured walkaround inspection program and digital database often struggle with paper-based routes and signoffs, lack of consolidated information, and an inability to properly analyze or act on the findings. Frustrations run high when route sequences are haphazard and when the same problems are reported over and over due to the absence of accountability and follow-through.

Additionally, data gathered in this manner tends to be inconsistent and of limited value. For example, lubrication state observations might be limited to basic oil level, oil condition, and oil leak checks. Lubrication rounds might capture the quantity of grease or oil added and maybe a checkmark. These two lists are likely separate documents, and any accompanying photographs or documentation are also disconnected from the record.

Continuing with the above example:

- From lubrication-related rounds, data captured may include when and how much grease was added, the type of grease used, meaningful information about oil levels (e.g., full, half full, quarter full, or empty), oil conditions (e.g., cloudy, milky, foamy, or particulates), leak details, photographs, and related pertinent information.

- From operator rounds, equipment reliability history is bolstered, such as whether the coupling guard was in good condition, the pump was leaking, wires were exposed, unusual odors, sounds, or sights were noticed, and equipment cleanliness.

The better rounds tracking systems also generate automated exception reports based on provided thresholds, enabling review of the issues – such as a static oil bath’s sight glass indicating a half full or lower oil level, or a suction pump bearing’s vibration amplitude exceeding a certain limit. This helps with escalating the highest priorities to work orders.

Polished programs nurture a culture of reliability

Maintenance and Operations teams are often quick to recognize the value of a well-run walkaround inspection program. Also, to best understand the full value of walkaround inspections, the history of cost savings of the most likely extent of damage should be utilized, if available, rather than just the overhead loss of the equipment repair. Being able to avert higher emergency work (e.g., call-in overtime or emergency delivery costs) should be included in the savings.

Though the initial impulse may be to consider it merely an additional responsibility, it soon becomes evident that the digital database specific to their plant and equipment is a necessary tool for working as a team with the condition monitoring/reliability leads and work planners, as well as for communicating with management and providing evidence of reporting new and existing issues.

Similarly, senior managers and executives value insights into downtime risks and potential production disruptions. Gaining executive support helps to ensure adequate resources and funding allocations to keep the program alive.

About the Author

Sidney Hand

Sidney Hand is CbM Specialist at Acuren Inspection, retired. Sidney began his maintenance career as a propulsion engineer with the U.S. Navy some forty years ago. His reliability maintenance expertise spans numerous industries, including mining, pulp & paper, chemical, oil, food, and more.

Ethan Frye

Ethan Frye is Senior Reliability Engineer for Pixelle Specialty Solutions. Early in his career, Ethan was a reliability engineer working alongside maintenance professionals. He transitioned into operations as an assistant pulpmill superintendent by age 23. He has a degree from James Madison University in Integrated Science and Technology (ISAT) and holds several industry-recognized certifications.

Forrest Pardue

Forrest Pardue is president and founder of 24/7 Systems Inc. After earning a BSEE at North Carolina State and then an MBA, Forrest has worked in the field of vibration analysis and PdM for more than 40 years. As one of the founding members of Computational Systems, Inc. (CSI), he was actively involved in the technical and market development of modern condition monitoring technologies. Following Emerson Electric’s acquisition of CSI in 1998, Forrest co-founded 24/7 Systems, a provider of reliability information management software and services.