Cutting through the fog: Using RACI to bring clarity to maintenance and reliability

Key takeaways

- RACI eliminates confusion by clearly defining who is responsible, accountable, consulted, and informed for each task.

- Clear RACI roles reduce downtime, streamline work orders, and improve communication across maintenance and reliability teams.

- Building RACI with the team creates buy-in, prevents red tape, and ensures it becomes a practical daily tool.

- Regularly reviewing RACI charts keeps accountability sharp, avoids duplication, and protects safety and compliance.

Walk out onto almost any shop floor and you’ll find the same scene play out sooner or later: a work order gets stuck in limbo. The technician says he or she is waiting on planning, planning says it’s in operations’ court to hand over the equipment, and operations is convinced maintenance owns it. In the meantime, the asset is failing, production is frustrated, the firefighting continues, and everyone’s pointing fingers.

It’s not that people don’t care. It’s that no one is exactly sure who’s supposed to do what, or who’s ultimately on the hook for making sure it gets done. In maintenance, reliability, and facilities work, that fog of responsibility is where downtime and inefficiency thrive.

This is where the RACI matrix earns its keep. At first glance, it looks like one of those simple project management tools consultants love to trot out – Responsible, Accountable, Consulted, Informed. (Full transparency: that’s what I used to think too, “here comes another trend!”)

But on the plant floor, RACI isn’t about theory. It’s about creating the kind of clarity that prevents confusion, streamlines communication, and makes sure work gets finished the right way, every time.

RACI in maintenance and manufacturing: Defining roles to eliminate downtime

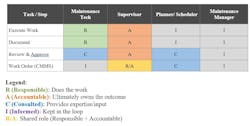

At its core, the RACI matrix is just a responsibility assignment tool. As you can see in Figure 1, it’s four simple letters mapped against the steps of a process. It’s not flashy, and it’s not complicated unless you make it that way. But when applied to maintenance and reliability, it can cut through the fog faster than just about anything else.

Here’s how a RACI matrix divides areas of responsibility:

- Responsible (R): the person (or people) actually doing the work.

- Accountable (A): the one person ultimately answerable for whether the work is completed correctly.

- Consulted (C): those who provide input or expertise to guide the work.

- Informed (I): those who need to be kept in the loop on progress and results.

Earlier in my career, I worked in an organization where an “I” mistakenly thought he was an “A.” He would dig in his heels on every decision, leaving no stone unturned, convinced he had to make sure the right choice was being made. The problem? That wasn’t his role. And because there was no RACI in place, he wasn’t entirely wrong.

Without clarity, everything feels like it needs your full attention. The result was a leader buried in weeds, pulled into every decision, and losing sight of the work that actually moved the business forward. Everyone wondered why he stayed in the weeds; from his perspective, he wondered why he was the only one in them.

That’s the trap RACI prevents. Too many “responsibles” leads to duplication, or worse, dropped tasks. No clear “accountable” leaves decisions watered down. And when half the plant is “informed” on everything, you end up with information overload instead of action.

Common pitfalls to watch for

Like any tool, RACI can backfire if it’s applied the wrong way. I’ve seen a few traps over and over again. Avoid these, and RACI stays what it’s supposed to be: a clarity tool, not another layer of red tape:

- Too many “Responsibles.” Assuming the other R is taking care of it will derail you more often than not.

- Multiple “Accountables.” If multiple people are accountable, no one is accountable.

- Over-consulting and over-informing. You waste a lot of time not executing here.

- Treating it as a one-and-done exercise. This isn’t flavor of the month, you want something to give you back some time.

- Failing to train people on how to use it. Use this in your onboarding and reinforce positive behaviors.

Where RACI adds real value to plant workflows

By clarifying who is doing what, who makes the call, and who simply needs an update, RACI turns chaos into a clear map of ownership that can be applied across everything from work order closeout to root cause analysis. There are several work process areas though where the benefits of using RACI can be felt immediately.

Handoff moments. Maintenance, reliability, and facilities work are loaded with handoffs. A technician identifies a problem, a planner builds the job, a supervisor assigns it, operations needs to sign off, and someone eventually has to close the loop in the CMMS. Each one of those steps is a chance for confusion and chaos if the roles aren’t nailed down. Before we put a RACI in place, everyone just did their best to keep the business moving. Work slipped through the cracks, some jobs were delayed, and most days felt like we were treading water. Once we laid out clear roles and responsibilities, everything changed. The planner owned incoming requests and planned the jobs, the supervisor scheduled and made sure the work got closed out, and the techs executed without second-guessing who was supposed to do what. That clarity kept the planner focused on planning and the supervisor effective in daily management. A strong RACI is like sheet music for an orchestra; it tells you who plays what and when. Instead of noise, the team started to move like a symphony.

Work management. Without RACI, planners often end up half-owning execution, supervisors chase down operations approvals, and technicians feel like they’re waiting on decisions that never come. A simple RACI chart that says who identifies, who approves, who plans, who executes, and who closes can prevent all that tail-chasing.

Formal reliability initiatives. Root cause analysis, preventive maintenance optimization, or RCM can easily stall out if everyone thinks they’re supposed to “approve” or if no one feels accountable for follow-up actions. A well thought out RACI forces clarity: one accountable for leading the analysis, the right experts consulted, the right leaders informed, and the actual data gathering assigned to someone responsible.

Facilities management. When you’re juggling vendors, compliance, safety inspections, and energy projects, the stakes are even higher. I know facility managers that get buried because they’re expected to personally “own” everything from vendor invoices to emergency response planning. Without RACI, the line between being informed and being accountable blurs, and suddenly the FM is in meetings all day, but the real work isn’t moving. Doesn’t that sound familiar?

With RACI, those same tasks are mapped clearly: the facility manager doesn’t have to be

everywhere, just where accountability truly sits. Talk about some real peace of mind for a FM!

Key benefits of RACI for industrial teams: accountability, efficiency, and safety

The common theme here is that when everyone knows their roles, the firefighting slows down. When no one knows, the firefighting never ends. The beauty of RACI isn’t in its complexity, but in how quickly it eliminates the gray areas where problems love to hide. For maintenance, reliability, and facilities leaders, the benefits stack up fast:

- Accountability and ownership. With one clear “A” per task, you never have to wonder who has the final say. This doesn’t just keep work moving, it builds trust over time.

- Better communication. By spelling out who is consulted and who is informed, RACI

keeps the right people in the loop without dragging everyone into every meeting or email chain. It’s also a good idea to call out the “RACI logic” so everyone understands WHY they are in that particular role. - Efficiency. Once you map the roles against a process, bottlenecks and redundancies stick out like a sore thumb. Fix those gaps, and suddenly the work flows cleaner. The first time you try this, you’ll probably see why that maintenance planner always seems overwhelmed.

- Safety and compliance. Some of the worst misses in our world come down to

assumptions. Everyone thinks “somebody” is handling safety checks or compliance reporting, that is until an audit or incident proves otherwise.

A RACI chart forces clarity on those critical steps and makes sure they don’t fall through the cracks. The bottom line: downtime thrives in confusion, and RACI starves it out by making ownership visible.

When RACI roles should shift – Sometimes “it depends”

Whether technicians should close out work orders themselves or hand that responsibility to supervisors is one of those classic “it depends” situations.

In some organizations, having techs close the WO works fine. The CMMS enforces required fields, techs are trained on accurate data entry, and supervisors only review exceptions. In others, supervisors or planners need to own closeout to protect data quality, compliance, and KPIs.

The key is remembering that a “best practice” may not be your best practice. Where your program sits on the maturity curve matters. If you’re still building the basics of data discipline, tighter control might make sense. If your team is trained and trusted, pushing responsibility closer to the work can free up leaders to focus on higher-level decisions.

How to implement RACI without the bureaucracy

I’ve learned from industry leaders like Ricky Smith and James Kovacevic, who stress the same core lesson: RACI is powerful only when it’s clear and owned by the team. Ricky focuses on making every task actionable and concise; so there’s no doubt about who does what. James emphasizes building the chart with the team, creating buy-in and accountability from the start. Their combined experience shows that when RACI is built right, it’s not theory, but a practical tool that speeds decisions, reduces rework, and keeps teams aligned.

One of the biggest risks with tools like RACI is that they get turned into paperwork exercises. The point isn’t to create pretty charts that sit in a binder or on the shelf in the office, it’s to make work easier. A few lessons stand out when putting RACI into play:

- Build it with the team, not for the team. We built it together, it’s not just what we were told to do.

- Keep it simple and visual.

- Review and refresh it regularly.

- Use a consistent format across departments.

- Don’t overload one person with too many “R’s” or “A’s.”

The key here is balance: RACI should bring clarity without turning into red tape. When it’s done right, the chart isn’t something you hide in SharePoint or check a box and say we did it, but a tool that teams actually want to use, because it helps them get their work done.

Call to action: Clarity beats chaos and builds trust

In maintenance, reliability, and facilities, gray areas are where downtime, rework, and frustration thrive. The RACI matrix shines a light into those gaps. It doesn’t just sort out who does what—it builds trust, drives accountability, and keeps leaders focused on the decisions that actually matter. So, grab a napkin, a whiteboard, or a scrap of paper. Pick one process that always causes frustration, maybe it’s work order closeout. In five minutes, sketch the R, A, C, and I. If your team can’t agree who owns what, you’ve found the first fire to put out.

Downtime loves confusion. RACI kills confusion. And when clarity becomes the norm, your organization is free to do what it does best—keeping assets reliable, safe, and productive.

About the Author

Trent McJunkin

Trent McJunkin, CMRP, ProFM, is an experienced maintenance and reliability professional with years of experience in the automotive industry. He has extensive background in automation, maintenance management, and advanced manufacturing methods, and is a frequent conference presenter and trade media contributor.