Photos from the Digital Manufacturing and Design Innovation Institute (DMDII)

On Thursday, UI Labs' Digital Manufacturing and Design Innovation Institute (DMDII), which serves as a test lab and project sponsor for new advanced manufacturing processes and technologies, announced it had been awarded $10 million in funding from the U.S. Department of Defense for this year, with an additional $20 million (at least) pledged over the next five years. At an event for the announcement at DMDII's facility in Chicago, Illinois Sens. Dick Durbin and Tammy Duckworth, Illinois Gov. J.B. Pritzker, Rep. Haley Stevens of Michigan (previously director of workforce development and manufacturing engagement at DMDII), and DMDII leadership all gave remarks about the crucial role that advanced manufacturing will play in the state's economic future as well in promoting national security, military readiness, and global economic competitiveness. In this gallery, Plant Services managing editor Christine LaFave Grace shares her photos from the event. (Also see Influential Women in Manufacturing's interview with Rep. Stevens.)

Chandra Brown, executive director of DMDII and previously CEO of a metal manufacturing company, emphasized DMDII's role as a connector and a facilitator of critical collaborations between industry and educational institutions--collaborations focused both on advancing new technologies through research partnerships and on training manufacturing's next generation of workers in the skills they will need to fill evolving manufacturing roles. "Training can take workers off the sidelines," Brown noted. (Hear Chandra Brown in an interview for the Manufacturing Tomorrow's Workforce podcast.)

The vision for DMDII was "to create the nation's flagship when it came to innovation, research and discovery for the manufacturing process," Illinois Sen. Dick Durbin said. "It would be about making sure that our defense industrial base was the best in the world and would continue to be in the future," he said, and about "how we as a nation could use that to be safe, No. 1, and No. 2, to be successful in this growing and changing economy."

"Thank you for keeping us on the cutting edge of digital technologies, for creating so many 21st-century manufacturing jobs, for helping ensure and maintain military readiness, and for bettering this state one project, one partnership at a time," Illinois Sen. Tammy Duckworth said in praising DMDII's work and growth over the past five years.

"DMDII shows us the power of investing in the future; it shows us how far we can go when we bring people together," Illinois Gov. J.B. Pritzker said in remarks at the funding announcement in Chicago on Thursday.

Getting data from legacy machines that are cost-prohibitive to replace can be a significant pain point for manufacturers and a hurdle in moving toward a more-predictive, more digitally focused production and maintenance model. DMDII partners look to address this issue with a solution that incorporates an off-the-shelf camera paired with machine-learning software to get and then analyze data from dials, gauges, etc.

The challenge of finding reliable suppliers for specialized precision parts was the focus of a DMDII project in partnership with Boeing and Missouri University of Science and Technology. The end result: a software tool that can virtually replicate a supplier's machines so that customers can readily and independently assess a supplier's capabilities.

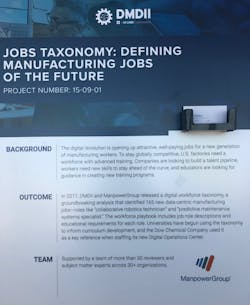

In collaboration with ManpowerGroup, DMDII in 2017 released a "digital workforce taxonomy" outlining 165 manufacturing workforce roles/titles of the future. The taxonomy is meant to serve as a guide that can inform both curriculum development in academic institutions as well as staffing initiatives and workforce planning and development within manufacturing organizations.

DMDII counts more than 300 industry partners in academia, heavy manufacturing, process manufacturing and beyond working to develop, test, and deploy new digital tools aimed at improving productivity, safety, manufacturing flexibility, and quality assurance in U.S. factories.

The entrance to the manufacturing floor at DMDII, which showcases projects focused on digital twin technologies, predictive modeling, 3D printing, design validation, and more.

Caralynn Nowinski Collens, CEO of UI LABS, DMDII’s parent organization, noted in her remarks that it was five years ago to the day that DMDII had launched.

Siemens demonstration area on the DMDII manufacturing floor.

Beyond announcing that it had secured $10 million in funding for this year and at least $20 million additionally over the next five years, DMDII celebrated its 5th anniversary on Thursday.