The Key to Energy Efficiency is Viewing a Total Facility as a “Single System”

Watson: If treating a total facility as a “Single System” is the key to energy efficiency, why do most in the Energy Efficiency Profession focus on the individual energy users instead of the Total Facility?

Holmes: I think a lot of it has to do with their training Watson. Whether it is in engineering school or the plethora of training courses now available to energy managers, people are taught to focus on the individual energy systems instead of the “Total Facility”.

Watson: I printed out the description for the “Fundamentals of Energy Auditing” course being offered this month by the Department of Professional Development at the University of Wisconsin in Madison. It says the attendees will “Study the types of energy systems installed in these buildings.” and “Analyze those systems to improve energy efficiency.” It also mentions temporary audit instrumentation and estimating techniques.

Holmes: I took that same Course at Wisconsin when I first entered the profession. Incredibly, the description of the current course is nearly identical to the one I took in the mid-‘70s.

How many other fields can you think of that are still providing the same entry-level training that they were 40 years ago? The presumption that the first tool developed on the heels of the Energy Crisis in the mid-‘70s is still the best, is ridiculous.

Watson: Even so, in 2015, more than 40 years since you took that course at Wisconsin, not only are Energy Audits accepted, more and more government agencies are requiring them. They are still being taught as the first step in every energy project even though, as far as we have been able to determine, there has never been a single scientific study that verifies the accuracy of Energy Audits.

Holmes: The antiquated methods they are teaching are part of what I refer to as the Bottom-Up Approach. Studying and analyzing all of the energy systems at the beginning of a project, before you know which ones are a significant part of the energy costs, wastes time and resources.

Energy Audits use "temporary instrumentation" along with “estimating techniques” to "guess" what the actual data would be if they actually had some. Not only do Energy Audits waste time gathering inaccurate and unnecessary information, their methods result in erroneous conclusions and recommendations.

Watson: Why waste time and money studying systems that turn out to be very small contributors to the energy costs? The most logical approach would be to find a way to first determine which systems are the most significant, then focus on those systems.

Holmes: We found a way to do that in 1979. The idea came from some of my students in a Thermal Systems class who were Nuclear Plant operators and managers. In order to account for the fuel used, they had to document where all of the energy went, do a Daily Energy Balance of the total facility. I thought if they could do it in a giant nuclear plant, I could find a way to do it in all of the facilities we were managing.

The key is to view the total facility as a Single System, and we developed a way to do that using what we have always called our “Top-Down Approach”. It’s based on sound engineering fundamentals, scientific problem-solving techniques and actual monitored (not estimated) data.

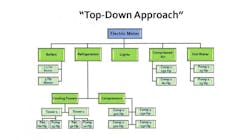

Watson: The utility meters are the most important points to monitor. They are at the top and provide the greatest amount of information; when every Energy Unit and Dollar is used. The analytics in the software are then able to use that data along with the date and time, outdoor temperature and humidity and building or production schedules to clearly show the relationships of those factors.

The transformers and main distribution panels are the next level down in the electrical system and provide the second most valuable source of information. And so on from the largest systems to smallest.

Holmes: Since, for the first several years we installed all instrumentation at our cost, and our only fees came from actual verified savings each month, we had to select key points that would allow us to create the greatest savings at the lowest first cost. We knew we couldn’t afford to spend money to monitor systems that weren’t significant so we found a better way to determine what we should monitor, the “Top-Down Approach”.

We discovered that we could get 80% of the required information by monitoring just a few key physical points. I was teaching thermodynamics, power systems, thermal systems, HVAC and other related classes for Purdue at the time so the software included sophisticated analytics to generate the rest of the data and present it in the most meaningful form.

Watson: I understand. The “Top-Down Approach” allows you to follow the “Heat In” through the facility until it becomes the “Heat Out”. Once you find where the energy goes, you can determine how much is being used efficiently and how much is wasted.

Holmes: We learned how to get the biggest bang for our buck; the most valuable information at the lowest cost required to create, maintain and document the greatest savings. We were initially amazed at how well this method worked. It allowed us to uncover huge problems and opportunities that everyone else had missed.

For more than 35 years this approach has resulted in savings of 20%, 30% and more from no-cost, low-cost changes alone, far exceeding the results from traditional methods that start with Energy Audits and require Capital Projects.

Watson: With little imagination and a reluctance to change, the rest of the Energy Profession remains stuck in the 1970’s and continues to pursue a Bottom-Up Approach based on estimated data and bad science.

What a shame that so many have continued to use antiquated methods that waste tremendous time, money and resources while missing most of the opportunities we find to generate huge savings through good management alone!

Contact Bill: [email protected]