Jim, manager, OH

Answer: Hello, Jim, and thank you for the compliment. In the "day-in-the-life" (DILO) study, an observer shadows a specific technician for his or her entire day’s work schedule. This process may take place during a single day (as implied by the name) or occur in whole-shift increments across multiple days. The goal is to understand the actual work being accomplished along with motion such as travel time, adherence to business processes, meeting attendence, and so on. In many ways, it is a deeper dive into the specifics of the activities. While wrench time can be measured as part of the activity, the results can be skewed more given that the individual knows that he or she is being "watched" for the entire shift given the shadowing nature.

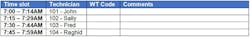

In contrast, a "wrench time" study is typically a sampling of multiple technicians across blocks of time to reach statistically significant conclusions about their activities. The following table shows a typical sampling matrix.

Table 1 – Sampling Matrix

The time slots and names are not shared with the technicians to preserve the integrity of the study. If the observer is not familiar with the technicians by name, numbers are placed on hard hats as examples. Based on the work schedule, the observer looks for Technician 101 – John – during that time slot and documents his or her observations using the wrench time code (WT code). These codes encompass activities such as direct-work wrench time, time spent looking for parts, time spent hunting for information, travel to/from the job site, and time spent waiting for equipment to become available. Other activities include breaks, lunch, meetings, etc. The observer can add additional comments, as well. It is important to randomize the sampling matrix to obtain a better sampling study. A wrench-time study conducted in this manner can last many weeks from an observation perspective to effectively sample the workforce. I’ll add that wrench-time study results can be skewed if schedules and teams are adjusted to accommodate the study, although they're likely to be skewed to a lesser extent than with a DILO stufy.

The results can be compiled in a database and reports generated from them. In this type of a study, you are not looking at individual actions but rather patterns of activity. For example, you may find the technicians gravitating back to the shop before the afternoon break and wrench time steadily dropping off until the shift ends. You would expect to see that in the final hour of the shift, but finding it before the afternoon break surprised one organization. On investigation, a business process had the planner-schedulers overestimating the job duration to avoid additional passes on the same work from their perspective. This overestimation caused the technicians to run out of work earlier than expected for any given day.

With both studies, it’s incredibly important that the technicians understand the activity is not penal in any way. There must be a partnership to gain trust and understanding among all factions of the organization. The goal is an improvement of business processes and other stakeholder partnerships. For example, if we are scheduling work in an operations agreement, and the study indicates that excessive time is lost waiting on equipment to become available for work, we have data with which we can approach our operations partner to determine how to resolve that issue. Continuous improvement is the goal. You need to focus on transparency and on sharing the findings with the workforce to create a positive experience.

Sadly, it is common for management to misuse the study findings, leading many technicians to rightfully distrust the study process. For example, we are typically requested to perform wrench-time studies in advance of union contract negotiations. The results are intended to determine pay and to justify staffing numbers. In cases such as these, we refuse the engagement because there is no partnership or trust in play.

What other insights might you have on this topic that did I not mention? Email at the address below and I will respond or place your questions with my answers here.

Please post your comments so everyone can learn.

Talk soon,

Jeff Shiver, CMRP

If you have problems in the fields of maintenance, reliability, planning and scheduling, MRO storerooms, or leadership as examples, please contact Jeff Shiver with your question(s) here.

About the Author

Jeff Shiver

Founder and managing principal at People and Processes, Inc.

Jeff Shiver CMRP is a founder and managing principal at People and Processes, Inc. Jeff guides people to achieve success in maintenance and reliability practices using common sense approaches. Visit his website www.PeopleandProcesses.com, and contact him on LinkedIn at www.linkedin.com/in/jeffshiver or via email at [email protected].