Industrial gas treasure hunt hits gold

One of the most common ways to reduce compressed air costs in industrial sites is to detect and fix compressed air leaks. Too often a significant portion of the compressed air produced by facility air compressors will escape through cracks and holes in system piping before it even gets to the final end use. A one cubic foot per minute leak in an industrial facility will cost at least $175 per year at 10 cents per kilowatt electrical cost. But in some facilities there are welding gasses that can cost far more than compressed air.

My journey of discovery started when I was offered a chance to try out some new instrumentation technology. When trialing a new Fluke ii900 ultrasonic industrial imager I offered a customer a freebie leak audit so I could put the new device through its paces. The imager uses an array of microphones to detect sound signals emitted by gas leakage and overlays the signature on a video screen for easy processing. A reporting feature will calculate the approximate leakage flow based on distance and decibel information. With this information a leak auditor can quickly detect, locate, and cost out leaks of all kinds; in fact it will detect more than common compressed air leakage, as I found out.

One day when scanning a large farm implement manufacturer, it took me about an hour to find and locate about 40 significant compressed air leaks costing about $4,000 per year. However, I also noticed a few small leaks in odd colored piping. It wasn’t until later I discovered that the facility used industrial shield gasses in their welding and laser cutting operations. Curious, I asked the customer to find out how much they pay for their Argon and Nitrogen. The answer floored me!

The value of compressed air training

Got water problems in your compressed air system? Check your temperatures

5 ways to get more for less from your air compressor

This particular customer was paying about $105 per year for every cfm of compressed air (full time operation 8,760 hours). I was very surprised to learn their Nitrogen cost was 65 times that of compressed air, and their Argon an amazing 335 times more! At this rate it doesn’t take much to add up to big savings.

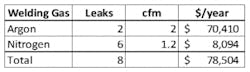

In all 8 small industrial gas leaks were found in about 45 minutes of work, adding up to a huge cost per year:

That is some hourly rate! So, if you are wanting to hunt for buried treasure in your industrial plant, try searching for your industrial gas leaks.