Use OEE as a metric to improve the profitability of your plant

Because the cost of storing large quantities of shop floor data electronically is now "trivial," managers can and should use continuous improvement metrics such as Operating Equipment Effectiveness (OEE) across their entire production lines to improve plant profitability. So says ARC's European Research Director Simon Bragg in a recent ARC Insight paper.

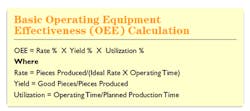

OEE is a useful, but underused metric derived from the multiplication of a plant's production rate, yield and utilization, and it should be part of any real-time performance management (RPM), continuous improvement initiative, says Bragg. Almost all automation, collaborative production management and enterprise resource planning software suppliers have production analysis tools or partners that support OEE calculations, he adds.

OEE focuses on the time wasted when the plant is not producing. It considers both machine downtime due to poor maintenance procedures and lengthy setups or slow machine throughput. It also provides analysis of the tradeoffs between driving equipment at a faster rate, but perhaps suffering a poorer yield during the start-up phase.

Bromford Iron and Steel, based in the United Kingdom, has successfully used OEE to remain profitable in a very difficult market.

Bromford monitors its entire production process, comparing different production operators, raw materials and final products on the plant's OEE. It also collects gas and electric consumption and the amperage on the rollers. The company compares current or worst performance with best performance and explains the difference to improve average performance.

Among the improvements Bromford has shown are a 20 percent savings in its energy bills and a $60,000 tax savings derived from meeting new government-mandated levies required by the Kyoto Agreement. Setup times improved by 10 percent and three products were dropped from production.

But Bragg points out that OEE is not a cure-all. In fact, except in industries where the cost of raw materials is negligible, crudely multiplying the three factors together can be inappropriate. It could increase because of better rate and utilization, but at the cost of diminished yield. The three factors must be studied separately as well as together, says Bragg.

OEE also lacks any notion of individual product profitability and costing; therefore, the analysis should include sensible average raw material costs for each product and an average running cost per hour, Bragg adds. He goes on to say that an initial analysis may lead to more questions, which usually requires additional data; consequently, analysts may want to add real-time costs at a later stage of the analysis to compare the effect of lower raw materials costs on machine rates.

For more information, go to www.arcweb.com.