A reflective white roof coating can diminish replacement and maintenance needs

The conditions on the roof are inhospitable. During summer, the temperature on a flat black tar roof deck may reach 170 F. During winter, it can drop to -20 F. That this environment quickly breaks down most materials is one reason relatively inexpensive and replaceable built-up roofs are so common.

Once the tried and true standard, we now know that black tar roofs are major contributors to the heat island effect, which has been linked to increased carbon dioxide levels in many urban areas. Much of the sun's heat conducts to the building interior to increase the demand for power while the air-conditioning system labors to maintain a comfortable working climate.

Studies conducted around the world long ago established the benefits of reflective roof coatings. The studies documented energy savings, a more comfortable work environment and, given proper maintenance and periodic recoating, a sustainable roofing solution that can last indefinitely.

Much of what's been written about white reflective roof coatings is true. Liquid-applied white roof coatings, to varying degrees, reflect solar radiation. Some are more effective than others; some are more durable and some have space-age additives that purportedly give them near-mythical qualities. It's virtually impossible to look into one bucket of roof coating and predict whether its contents are going to perform better than the contents of somebody else's bucket. That's why specific guidelines have been established for testing and approving liquid-applied acrylic roof coatings. A liquid-applied acrylic roof coating that meets or exceeds the standards clearly displays its credentials on the label. Look for them when evaluating this class of product.

ASTM D6083

ASTM International is a not-for-profit organization providing a global forum for the development and publication of voluntary consensus standards. ASTM International produces standards accepted and used in research and development, product testing, quality systems and commercial transactions around the globe.

ASTM D6083 refers to liquid-applied, water-dispersed, 100 percent acrylic elastomeric latex coatings used as a protective roof finish. The standard establishes minimum performance standards for the following physical properties.

Viscosity.

Elongation.

Tensile strength.

Accelerated weathering.

Permeance.

Water swelling.

Adhesion.

Tear strength.

Low temperature.

Underwriters Laboratories Inc.

UL is an independent, not-for-profit product safety testing and certification organization. Roof coatings specifications often call for a UL 790 Class A fire rating in accordance with ASTM E108.

International Conference of Building Officials

ICBO, a nonprofit, public-benefit corporation, evaluates building products, components, methods and materials. The evaluation culminates with code compliance reports, which are distributed internationally to building regulators, designers, specifiers, architects, engineers and others. Vendors count on reports from ICBO Evaluation Service as third-party evidence their products and systems meet code requirements.

Factory Mutual Research

FM is an affiliate of FM Global, one of the world's largest insurance companies. Its research sets new standards that advance loss prevention practices and help develop new products. In addition, manufacturers use Factory Mutual Research's services to earn the FM Approval mark. It certifies, after rigorous testing, the reliability of products and services.

California State Fire Marshal

The State Fire Marshal supports the California Department of Forestry and Fire Protection through fire safety responsibilities, including regulating buildings in which people live, congregate or are confined and by reviewing regulations and building standards, among other things.

ENERGY STAR

The Environmental Protection Agency says the U.S. spends approximately $40 billion annually to air-condition buildings. This is one-sixth of the total electricity generated in a year. ENERGY STAR-qualified roofing products reduce interior temperatures, thereby reducing the air conditioning load, which, in turn, can help reduce energy bills by as much as 50 percent.

Waterproof, workmanship, warranty

Providing a waterproof barrier from the elements is the primary objective of any roofing system. High-quality roof coatings resist the effects of ultraviolet light, ponding water and pounding rain. The ability to withstand the elements depends largely on the coating thickness and the ratio of acrylic solids to filler materials.

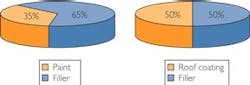

To determine an appropriate thickness for a high quality acrylic roof coating, compare it with paint. The industry standard thickness for commercially applied exterior acrylic house paint is three to four mils of dry film thickness. An elastomeric roof coating requires a minimum thickness of 20 to 25 mils if it is to remain stable and protect over time (see Figure 1). A greater film thickness also optimizes the membrane's elongation and tensile strength. It boils down to 20 to 25 mils of protection on the roof versus three to four mils of color on the siding.

Figure 1. Comparison of paint and roofing thickness.

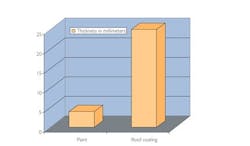

In addition to thickness, other issues warrant discussion. Paint has approximately 35 percent solids (by volume), whereas quality roof coatings have more than 50 percent solids (see Figure 2). A coat of paint is applied at the rate of 300 to 400 sq. ft. per gal., whereas roof coatings are appliled at the rate of 65 sq. ft. to 100 sq. ft. per gal.

Figure 2. Relative amounts of filler in coatings.

Proper installation

Workmanship is a key variable in roof coating longevity. Pipes, soffets, drains and other roof details must be reinforced properly with fabric or high-strength butter-grade material before coating the roof. These detail areas are where damage most frequently occurs. Ignoring the detail reinforcement introduces the risk of roof failure.

The roofing contractor should offer proof that the coating manufacturer has certified him to apply the product. Similarly, an in-house maintenance crew must have at least one person trained in proper application and product maintenance. Always remember to request an MSDS and have it readily available at the site in the event of an accident.

The product warranty and the manufacturer's ability to stand behind it financially also are important selection criteria. For fairly small areas, the warranty printed on the can probably will suffice. For projects of 10,000 sq. feet or more, obtain a copy of the signed warranty the manufacturer keeps on file. Read it carefully. This type of warranty may offer extension packages with periodic inspection and recoating programs designed to sustain the coating system for the life of the roof.

Remember the standard warranty caveat. If the roof's structural integrity is compromised or if patching can't solve the problem, an elastomeric coating most likely will not solve it either. When the roof structure is shot, replace it.

One size can't fit all

The marketing thrust behind many liquid applied acrylic roof coatings implies that the content within the bucket includes all the ingredients necessary for virtually any roof coating projectfrom thin aluminum mobile home roofs to massive concrete sports arenas. This is trueto an extent. The stuff in the bucket will result in a white roof, regardless of the substrate to which it's applied. Whether it actually meets expectations is a matter determined by dry film thickness, atmospheric conditions (including those during the application) and the ratio of solids to filler. Atmospheric conditions also may dictate the need for a boosted biocide for increased alga resistance.

Superior coating products represent just one element of a complete system that includes primers, mastics and reinforcing fabrics. Each combination is specifically designed for a given substrate. This ensures the building owner gets the right combination of materials for a particular roof in a particular location.

Some roof projects require embedding reinforcement fabric, or mesh, into the acrylic coating to reinforce a marginally unstable or weakened area. If used over the entire roof, this technique produces a durable, fully adhered, seamless membrane that requires no fasteners, adhesives or heat welding.

Long-term sustainability

Elastomeric coatings sustain, or extend, the roof substrate's service life. Applying a thick, durable coating virtually eliminates the need to replace the roofing material periodically. If kept structurally sound, all that's required for a roof to perform like new is to reapply a topcoat of acrylic roof coating periodically. This fact represents a significant cost savings because it eliminates the costly disposal of the old roofing material in already overtaxed landfills.

Roof insulation

Misconceptions concerning reflective roof coatingsmany of which allege to contain space-age materialsabound. One such issue is insulation value. A material's R-value is a measure of its resistance to the passage of heat, a resistance that applies equally in both directions. Roof insulation prevents summer heat from passing through the building envelope to the interior. By the same token, the very same insulationto the very same degreeprevents heat from escaping to the exterior during the winter months.

A reflective coating reflects solar heating away from the roof. A reflective coating won't act as an effective thermal barrier that prevents heat transport in either direction. It's misleading to promote a reflective coating as having any significant R-value.

The only relationship an elastomeric roof coating has with increasing a roof's insulation value is as a protective layer applied over a layer of supplemental insulation. Coincidentally, this also is the only measurable means by which the coating can contribute significantly to sound resistance.

Research the market

While this article has focused on 100 percent acrylic roof coatings, a wide variety of liquid-applied reflective roof coatings systems are available, including urethane, silicone, Hypalon and other synthetic rubbers. Acrylic technology evolved from the same material used in heavy-duty caulks and industrial sealants. The 100 percent acrylic coatings having third-party certification that they conform to ASTM D6083 standards offer further assurance of receiving a quality roof coating system. This standard, along with ENERGY STAR compliance, ICBO, UL, and FM certification are important factors to look for when selecting a coating. Look for a manufacturer that offers custom-tailored coating systems designed to sustain the entire rooffrom large flat areas to details and transitions. Finally, don't overlook the warranty. Your roof is not only a major expense, but it also protects everything that lies beneath. Look for a coatings manufacturer with a proven track record and customer testimonials to back up its claims.

Clint Whitsett is marketing coordinator and Bill Mann is vice-president of international sales and marketing at UNITED COATINGS in Greenacres, Wash. They can be reached at http://www.unitedcoatings.com or 800-541-4383.

|

More information about the organizations mentioned in this article is available on the Web and in print. ASTM http://www.astm.org/cgi-bin/SoftCart.exe/ABOUT/aboutASTM.html?L+mystore+lfrt3480+1037647022ICBO http://www.icbo.org/ICBO_ES/index-who.htmlCalifornia Office of the State Fire Marshal http://osfm.fire.ca.gov/aboutus.htmlENERGY STAR "ENERGY STAR for Roof Products, Fact Sheet for Manufacturers," http://energystar.gov |