Labor utilization

A recent study by the United Nations' International Labor Organization ranked U.S. workers as the world's most productive. Although workers in France, Belgium and Norway beat the Americans in productivity per hour, the report says, we work more hours, an average of forty-six 40-hour weeks per year. Too bad this isn't true of our maintenance organizations. Compared with its world-class production performance, U.S. maintenance departments seem to work ineffectively and inefficiently.

|

View related content on PlantServices.com |

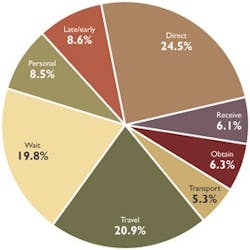

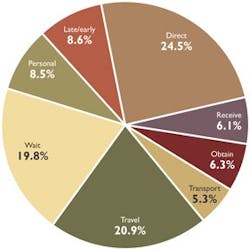

Manpower or labor utilization within maintenance departments continues to fall far behind its production counterpart. Statistically, only 24.5 percent of a typical craftsperson's day is spent on productive tasks. The remaining 75.5 percent is consumed with unproductive activities. Figure 1 illustrates typical losses.

Slicing the day

Figure 1. Typical craftsperson's time distribution

Most losses associated with maintenance work can be attributed directly to lack of planning and ineffective supervision. Simply improving these two areas could easily reverse the 3-to-1 ratio.

Travel time

Having to move around unnecessarily represents 20.9 percent of the wasted time. Proper planning in both distributing maintenance personnel and organizing preventive and corrective maintenance task routes could eliminate most, if not all, of these losses. Maintenance resources should be positioned as close as possible to the where the work is to be performed, and task routes configured to minimize travel distance and time.

Personal time

It's hard to justify a workforce stretching breaks, making telephone calls and exploiting a variety of other personal reasons for not working. Proper supervision would eliminate most of these losses, but company policies must be enforced universally on every worker, plant and office before the losses can be eliminated totally.

Acquired sick leave privileges are often abused. Workers earn or acquire sick days based on length of service. In many cases, the accrued time can represent more than six weeks of paid leave. While this is earned leave, a growing number of maintenance workers are using it as additional vacation time. The result is a dramatic reduction in the net available workforce. As a result, needed maintenance isn't performed.

Waiting for instructions

No craftsperson should waste 19.8 percent of any day waiting for instructions! A full day's work should be assigned to each craftsperson before the shift starts. Ideally, assignments for the next day should be made before the end of today's shift, but certainly no later than the beginning of the next shift.

Late/early

Employees who arrive late or leave early lose at least thirty minutes each day. In extreme cases, these losses can represent an hour or more per person. Proper supervision would capture these losses, but everyone must be held accountable for adhering to company policies on the matter.

Obtaining materials

Time is wasted when workers must fetch permits, materials, tools, reference materials and other documentation required for completing an assigned task. Proper planning will eliminate these delays by having the necessary materials, including permits, on hand at the work site as part of the work package. Repair parts and tools should be "kitted" and delivered to the work site. Permits, drawings and other documentation should be linked to the appropriate preventive maintenance task list or work order and distributed to the craftsperson with the work package.

Each of these drains may be small in itself, but, together, they have a dramatic impact on maintenance productivity, especially when one considers the other losses that are a part of manpower utilization. For a typical workforce of 100 workers, each having a burdened labor rate of $75,000 per year, these losses represent a substantial economic drain equal to 67 full-time equivalent people each year, more than one-half of the payroll workforce.

FTE = (6.04 hr/person-day) x (100 persons) x (5 day/wk) x (46 wk/yr) x (yr/2,080 hr) = 66.79

In addition, there is a financial loss of $5,009,250 per year for non-productive time.

Loss = (66.79 FTE) x ($75,000/FTE) = $5,009,250

Neither of these losses is acceptable and could be resolved with effective resource planning and supervision.

Effective planning

In a world-class organization, maintenance activities are planned and scheduled fully. Doing so ensures that each craftsperson has a full day's work and that little time is wasted looking for parts, tools and documentation. Preventive maintenance routes are configured to minimize travel time and are "load-leveled" to match work requirements with net available workforce. In addition, maintenance tasks are sequenced to minimize the mean-time-to-repair or mean-time-to-inspect for each planned task or work order.

Effective supervision

The maintenance workforce will perform work that gets "inspected," not necessarily what management needs to have done. So frontline supervisors must monitor work performance directly. They should structure their time so that they spend at least sixty percent of their day on the floor inspecting work performance.

Effective labor-hour utilization

With effective planning and supervision, the labor-hour utilization should be at least 85 percent, based on net available workforce. This level assumes that work is fully planned and that effective supervision, company policies and procedures are applied universally across the plant. Regardless of what you think, "time is money" and lost time, no matter how trivial each instance may seem, is unacceptable.

Figures: R. Keith Mobley