Hello DALI

Without a doubt, plant operations have achieved an unprecedented level of sophistication. Electrical products and energy systems have been imbued with intelligence air compressors have self-contained sensors, pumps monitor their own health, and industrial networks allow plant managers to monitor the entire plant floor from the office.

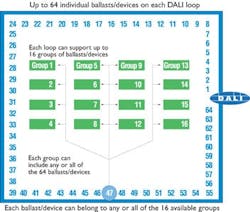

Because lighting accounts for as much as 25% of the typical plant's energy cost, it comes as no surprise that lighting technology has evolved in the same direction. Today, plant professionals can have lighting intelligence, flexibility and two-way communication through a system known as DALI.Tagging ballastsThe Digital Addressable Lighting Interface (DALI) is a communication protocol specifically for lighting systems. This open standard was established in Europe and has been adopted in North America, where mainstream applications are embracing it.The best way to think about how DALI works is by analogy with a typical suburban subdivision. Consider a street with many driveways branching from it. Each driveway ends at a house, each with a unique address and activities taking place.Related to DALI, the house represents the ballast, the driveway represents the ballast's connection to the street, and the street is a low-voltage, two-wire control bus. Typically, the control bus also referred to as a loop is powered at 16 VDC. In this imaginary DALI-ville, streets can have as many as 64 houses connected to them.A signal emanating from a control point operates the ballast. This controller may be a computer, wallbox device or sensor. Establishing a communication link requires each ballast to have its own address. A PC or wallbox scene controller sends a command to the ballasts and any other DALI device on the loop to randomly address itself with a 24-bit long-form address (enabling more than 16 million possibilities). The PC or wallbox then randomly assigns a simplified short-form address to each long address in numerical order from 1 to 64 (see Figure 1).Just as each house has its own individuality, so does each ballast, and the memory residing in a ballast may be modified, or painted, to meet the needs of the space occupant. For example, the resident in office No. 1 can have the lights set at 75% output and the resident of office No. 2 can set output at 50%, while the adjacent manufacturing cell selects 100% light output. Although these fixtures are connected to the same power circuit, DALI establishes lighting control circuits that are independent of power circuits.The system's brains reside in the ballast, not in a control panel, where it would take up valuable space at a remote location. The controller sends a DALI signal onto the loop. The control signal might order the ballasts to run program 3, at which point each ballast recalls program 3 from its memory and responds accordingly. The response could be anything from 'turn on'to 'turn off' , 'dim up' , 'dim down' , or another specific command the DALI protocol prescribes.DALI applies existing digital technology to a new application. Since the early 1990s, DDC controls have been available to the HVAC industry, and the lighting industry caught up to the technology.

|

View related content on PlantServices.com |

Figure 1. Like a subdivision map showing how streets, driveways and houses are connected, this schematic of the DALI network illustrates how ballasts are connected in a logical manner.

At the plant level

DALI offers a lighting system with three previously unavailable characteristics: intelligence, flexibility and two-way communication. Because the ballast now contains software, it is a smart device.Imagine the convenience of controlling a lighting system from a desktop and the flexibility to relocate fixtures and adjust grouping without having to worry about lighting circuit details. Moreover, two-way communication gives the maintenance engineer up-to-the-minute reports about performance shifts, system faults as well as lamp and ballast failures. When the engineer needs to modify the lighting, a DALI system accommodates moves, adds and changes instantly without costly rewiring. This flexibility makes it easy to adapt lighting to future needs and requirements, customize lighting to space requirements, and evolve the lighting to fit changing use patterns.Many manufacturing plants switch the lighting at the breaker panel, but many times access to breaker panels is obstructed. Therefore, lights may operate continuously although the plant doesn't. Additionally, even if the panel is easily accessible, switching breakers repeatedly can lead to premature spring failure. Controlling the entire facility's lighting from a computer maximizes both energy and maintenance savings.As the use of robotics increases, the need for targeted, high-quality lighting increases. There's no need to waste energy, light and lamp life in fully automated locations. DALI enables plant professionals to dim or turn off the lights in these areas selectively or, when maintenance is required, to turn on only the individual light that's required.As more facilities move toward real-time power supply, the need to control electric loads increases. A DALI system provides the ability to reduce lighting loads to decrease peak demand. In many instances, power in light fixtures can be reduced by as much as 20% with little or no discernable reduction in lighting levels.

At the plant level

DALI offers a lighting system with three previously unavailable characteristics: intelligence, flexibility and two-way communication. Because the ballast now contains software, it is a smart device.Imagine the convenience of controlling a lighting system from a desktop and the flexibility to relocate fixtures and adjust grouping without having to worry about lighting circuit details. Moreover, two-way communication gives the maintenance engineer up-to-the-minute reports about performance shifts, system faults as well as lamp and ballast failures. When the engineer needs to modify the lighting, a DALI system accommodates moves, adds and changes instantly without costly rewiring. This flexibility makes it easy to adapt lighting to future needs and requirements, customize lighting to space requirements, and evolve the lighting to fit changing use patterns.Many manufacturing plants switch the lighting at the breaker panel, but many times access to breaker panels is obstructed. Therefore, lights may operate continuously although the plant doesn't. Additionally, even if the panel is easily accessible, switching breakers repeatedly can lead to premature spring failure. Controlling the entire facility's lighting from a computer maximizes both energy and maintenance savings.As the use of robotics increases, the need for targeted, high-quality lighting increases. There's no need to waste energy, light and lamp life in fully automated locations. DALI enables plant professionals to dim or turn off the lights in these areas selectively or, when maintenance is required, to turn on only the individual light that's required.As more facilities move toward real-time power supply, the need to control electric loads increases. A DALI system provides the ability to reduce lighting loads to decrease peak demand. In many instances, power in light fixtures can be reduced by as much as 20% with little or no discernable reduction in lighting levels.

Figure 2. The DALI technology allows the extent and level of plant illumination to closely track the activity level on the plant floor, thus minimizing electricity consumption.

Digging deeperA DALI lighting system has no barriers to its use. The system may be used for both interior and exterior applications. NEC Class 1 and Class 2 wiring is allowed (consult local codes). The only limitation is the lack of a full range of ballast and control offerings.As with any new technology, some users jump right in while others embrace it gradually. This is the situation with DALI. Do your homework before deciding on a DALI installation to ensure the controls and ballasts are available. From a DALI perspective, development of fluorescent ballast technology has progressed further than that of HID ballast technology. For controls, only a limited number of vendors have developed DALI-compliant systems, although many building management systems have interfaces for DALI to communicate with proprietary systems.Is DALI the perfect fit for every application? Of course not. If you don't have a complex facility, don't want two-way communication, or don't need load-shedding capabilities, then a DALI system might be more than you require. However, in most facilities, DALI will enhance your building's performance.In truth, the sky's the limit with a DALI control system. It provides everything a traditional 0-10 VDC system offers, plus more. Talk to it. It can talk to you. Regroup fixtures without getting on a lift/ladder. About the only thing a DALI system won't do is change its own lamps. As more control and ballast manufacturers embrace the protocol, 0-10 VDC systems will all but disappear.Environmental issuesAnother benefit of DALI is that, from an environmental perspective, it can help conserve natural resources, reduce health and safety risks, and improve employee satisfaction and productivity. Identified as a green and environmentally friendly product, DALI supports sustainable design, positively contributing to the purification of the environment and enabling the use of popular and energy-efficient daylight harvesting strategies.By putting intelligence inside the ballast, DALI transforms it into a smart device that allows users to establish any desired lighting system configuration. DALI is versatile enough to work with the most sophisticated building management systems. It's especially suitable for plants that wish to gain the benefits of automated energy conservation efforts through daylight harvesting, load shedding, occupancy pattern tracking and others. The DALI protocol gives plant managers the ability to track, archive and evaluate their lighting investments easily.DALI opens new possibilities for automating the lighting control system and supporting sustainable design at the plant level. Stuart Berjansky is senior product manager of controllable lighting for Advance Transformer Co. in Rosemont, Ill. E-mail him at [email protected].Figures: Advance Transformer Co.

Digging deeperA DALI lighting system has no barriers to its use. The system may be used for both interior and exterior applications. NEC Class 1 and Class 2 wiring is allowed (consult local codes). The only limitation is the lack of a full range of ballast and control offerings.As with any new technology, some users jump right in while others embrace it gradually. This is the situation with DALI. Do your homework before deciding on a DALI installation to ensure the controls and ballasts are available. From a DALI perspective, development of fluorescent ballast technology has progressed further than that of HID ballast technology. For controls, only a limited number of vendors have developed DALI-compliant systems, although many building management systems have interfaces for DALI to communicate with proprietary systems.Is DALI the perfect fit for every application? Of course not. If you don't have a complex facility, don't want two-way communication, or don't need load-shedding capabilities, then a DALI system might be more than you require. However, in most facilities, DALI will enhance your building's performance.In truth, the sky's the limit with a DALI control system. It provides everything a traditional 0-10 VDC system offers, plus more. Talk to it. It can talk to you. Regroup fixtures without getting on a lift/ladder. About the only thing a DALI system won't do is change its own lamps. As more control and ballast manufacturers embrace the protocol, 0-10 VDC systems will all but disappear.Environmental issuesAnother benefit of DALI is that, from an environmental perspective, it can help conserve natural resources, reduce health and safety risks, and improve employee satisfaction and productivity. Identified as a green and environmentally friendly product, DALI supports sustainable design, positively contributing to the purification of the environment and enabling the use of popular and energy-efficient daylight harvesting strategies.By putting intelligence inside the ballast, DALI transforms it into a smart device that allows users to establish any desired lighting system configuration. DALI is versatile enough to work with the most sophisticated building management systems. It's especially suitable for plants that wish to gain the benefits of automated energy conservation efforts through daylight harvesting, load shedding, occupancy pattern tracking and others. The DALI protocol gives plant managers the ability to track, archive and evaluate their lighting investments easily.DALI opens new possibilities for automating the lighting control system and supporting sustainable design at the plant level. Stuart Berjansky is senior product manager of controllable lighting for Advance Transformer Co. in Rosemont, Ill. E-mail him at [email protected].Figures: Advance Transformer Co.