Light-emitting diodes represent a rapidly evolving technology that’s supplanting traditional lighting in a number of applications. Most people are familiar with the use of LEDs as indicators or direct-view devices. We see them in common use as the small indicators in electronic equipment, traffic lights, exit signs, large video displays, automotive lighting, cell phones and more. Many portable lighting sources are now using LED sources as well. What’s less known and appreciated is the growing use of LEDs as illumination sources that provide an alternative to existing lighting technologies.

The transition from traditional light sources to LEDs is similar to the shift from vacuum tubes to transistors in electronics. LEDs, too, are solid-state devices, but they require neither glass envelope nor exotic gas to generate illumination. Solid-state lighting is emerging rapidly and has already supplanted traditional lighting sources in several applications.

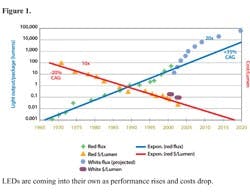

Invented in 1962 by a researcher at General Electric, it’s only within the past seven to eight years that LEDs began to be used for illumination, as well as indication. The earliest LEDs were red, but over time, additional colors (which are the result of the materials used in manufacturing the LED device) have emerged, including high-brightness devices available in red, green and, most recently, blue. Today, high-brightness LEDs are available in many colors, including white. Color systems use a mix of red, green and blue LEDs to produce many colors, the range of which is large and includes deep, saturated colors, as well as pastels and white.

Light-emitting diodes convert electricity directly into light — electrons to photons — through an electrical junction of semiconductor material. The exact materials and the resultant electrical characteristics determine the color of light being emitted. LEDs produce a relatively narrow wavelength of light and the colors are pure. White LEDs are actually blue LEDs dosed with color-converting phosphors that produce a broad emission of white light. This mechanism is similar to that used in fluorescent lamps, which produce white light using invisible ultraviolet light.

During the past five years or so, this improvement has reached levels that make LEDs suitable for general illumination. Any color application can likely be addressed through the use of LEDs, and the white light versions are marching up the same lighting curve. From indicators to marker lights, accent and decorative lighting to signage, LEDs are becoming ubiquitous.

Cost of light

When you purchase a lamp or bulb, your upfront cost is only a fraction of the total cost of using it. The operating cost for a 100-W incandescent lamp, for example, can be as much as 10 to 20 times its purchase cost. The true cost of light, however, can well exceed that and you should take into account not just the first cost, but also the lifetime cost of operating a lighting system.

The relevant metric here is dollars per million lumen-hours. It’s similar to dollars per kilowatt-hour used for the cost of electricity. Instead of tracking electrons however, it tracks photons. On this basis, solid-state lighting is moving rapidly into the territory of traditional lighting.

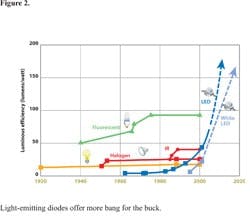

Efficacy

Efficacy is the ratio of light output to electrical power input and has the units of lumens per Watt (LPW). LEDs have continued to improve by this measure and producers’ laboratories are seeing efficacy levels as high as 100 LPW for particular colors. In white LEDs, package efficacies are typically in the 25 LPW to 35 LPW range, with devices emerging in the 40 LPW to 60 LPW range. Recent announcements by LED manufacturers show 60 LPW to 70 LPW ranges for 2005. Although this represents device efficacy, it doesn’t necessarily imply that fixture efficacies are as high.

Although high-quality fluorescent lamps and other lighting technologies can provide at least 70 LPW to 90 LPW, this doesn't tell the whole story. A fluorescent tube is an omnidirectional radial line source and much of the light must be redirected if the tube is to provide useful illumination. As a result, fixture efficiency can be as important as source efficiency. Task lighting, for example, provides illumination at a work surface. Several examples of LED-based sources with nominally lower lpw actually produce in higher lighting levels at the work surface in comparison to a traditional lighting source.

| Leds offer the following unique features and attributes: |

|

Energy savings

LED-based illumination has now been used in nearly every type of lighting market. Many applications require color, but new generations of lighting fixtures based on white light are providing many of the same benefits. For example, an 11-story building in Las Vegas (Figure 3) is using solid-state exterior lighting. Energy and maintenance costs of the former metal halide lighting were excessive and the switch to LEDs is estimated to be saving about $40,000 per year in energy and maintenance costs.The bright future

LED-based white light sources also are making rapid progress and a number of such products are now or will soon be on the market. With the advantages it offers and its light quality, as well as the ability to produce specific color temperature light sources, these new white light sources will offer a host of benefits for future lighting needs.

With all the development, however, the simple concept of a retrofit lamp is but one way to think of solid-state lighting systems. The features and capabilities of solid-state lighting systems exceed the benefits of gas, glass and brass found in traditional lighting. Designers, illumination engineers and plant professionals have an opportunity to reinvent lighting in a way that makes sense for an application. The bulb culture, as it is sometimes termed, isn’t simply a replacement product but a rethinking of lighting —– luminous surfaces, matching daylight, intelligent lighting systems and more. The technology itself is exciting, but the opportunities for control, integration and more are even more exciting.

Kevin Dowling, Ph.D., is VP of Strategy and Technology at Color Kinetics Inc., Boston. Contact him at [email protected] and (617) 701-2236.