Enough has been written during the past few years to convince most plant managers of the benefits of connecting plant floor equipment and processes to the Internet or Intranet. So, now that we’re convinced of the benefits of Web-enabled automation, what pieces and parts are required to put this technology to work?

The basic parts required for Web-based data acquisition and control are:

- An interface to the machine or process to be monitored or controlled via the Web (network) connection.

- A Web server to make the desired display and control pages available to the remote browser or client.

- A data service or interface to handle exchanging data between the local machine or process (server) and the remote system (client).

The only requirement for viewing data and Web pages remotely is a standard browser interface. Applications featuring statistical process control, optimization or enterprise level software to exchange real time data with the machine/process require a remote server PC and a compatible data exchange service. Figure 2 shows a simplified block diagram for the parts.

Figure 1: Equipment connects to the Internet through a local interface unit.

The server

The Web server/data service device—a “thin server”—provides the connection between the machine or process and the Internet. A connection to an existing PLC or proprietary controller is required to extract data or enable control over the equipment. Most PLCs, including products from AB, Schneider/Modicon and Siemens, support at least a serial connection using communication protocols available from the PLC vendor or third-party suppliers. In many cases, the communication driver is available from the thin server vendor as part of the embedded software application.

Equipment that uses a standard PLC protocol or supports another open standard protocol, such as Modbus RTU or TCP, greatly simplifies the job of connecting the thin server. However, this is not always the case.

If the equipment uses a non-standard PLC or a proprietary controller, a connection to the thin server device is still possible, as long as the controller supports some kind of serial protocol and the vendor can provide protocol documentation. Then, either the thin server vendor or a third-party developer will be involved for driver implementation.

In the extreme case, the monitored equipment may have a controller with no external communication port, or the protocol may be unavailable for some reason. If so, it may be necessary to instrument the equipment or process externally using additional sensors and appropriate I/O to monitor strategic data or equipment control points. Choose those that support a standard communication protocol (e.g. Modbus or an open ASCII protocol) and can be connected to the thin server. Alternatively, an I/O device may be selected that includes an integral thin server function. If the I/O device includes an integrated server, the separate thin server may not be required.

Linking

After installing a thin server and proper driver in the equipment enclosure, the next step requires configuring the thin server to link the equipment communication data and control (inputs and outputs) to the network. Details depend on the features and configuration software provided with the thin server. For example, a gateway server may do nothing more than map PLC registers to network variables or a remote PC connection. Sophisticated thin servers may allow configuration of a Web page to view equipment data, enable alarm monitoring and data trending, add standard connectivity interfaces, such as OPC, and may even support paging a response team when programmable equipment fault conditions arise. Make sure that the selected thin server allows for future expansion.

The Internet or Intranet (LAN) connection to the thin server may include a standard hardwired Ethernet line, a modem/phone line (dialup) or a wireless connection (802.11b Ethernet, for example). The type of thin server and existing plant network infrastructure—or lack of network infrastructure—usually determines the connection.

If a hardwired LAN already exists near the equipment, a network connection is relatively simple with the addition of a cable drop. If complex cable runs or long distances make a hardwired connection difficult, a wireless connection may be the best alternative.

However, when selecting wireless connections, be sure to evaluate the proposed installation site carefully and consider factors, such as range and signal integrity. Look for a wireless thin server that supports a wireless LAN interface to simplify installation.

Figure 2: Block diagram of PLC, Web server and network

Examples

Now that we’ve seen the power of Web-enabled automation and reviewed how to implement it, where do we go from here? Let’s take the sample architecture from the previous section and see how it could be implemented.

Thin server: Use a complete “intelligent embedded server” solution that includes hardware and runtime software required to Web-enable a system. This better grade of server can connect to a device (machine/process controller, I/O, sensor) using a standard RS-232/485 serial port or an optional Fieldbus adapter. A network connection is then made through a standard Ethernet 10/100BaseT port or via optional modem or wireless network/Internet connection. Development software enables Web pages and data connections to remote application software to be created and maintained easily from anywhere via the network connection. It provides security through password-protected user login and optional restricted access on the basis of user IP.

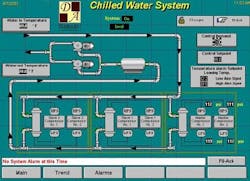

For an application requiring a local HMI to be Web-enabled, consider an operator interface terminal that combines the features of a thin server with integrated LCD and HMI software functionality.

Browser/thin client: Several choices exist, depending on the need. Any standard laptop or desktop with browser software can access the Web pages resident in the thin server, providing instant access to information about equipment, plant, process, building or business worldwide. For access from the plant floor or locations requiring a ruggedized viewer, a high-grade industrial HMI from can provide browser capability along with full PC expandability and functionality.

If full PC functionality is not required, try a thin client terminal that supports viewing of remote Web pages via its integrated Ethernet connection and standard Internet Explorer software. This version of thin client also supports third party or custom HMI applications based on Windows CE or Linux, including support for Java.

Web-enabled automation offers real benefits and provides real competitive advantages for your enterprise. And, with solutions highlighted above, it can be easy and cost-effective to make Web-enabled automation a reality.

Mike Rothwell is director of Automation Engineering Center, Advantech Automation Corp. He can be reached at 513-742-8895, ext. 122 or [email protected].