Instrumental analysis methods significantly increase product quality

Monitoring and controlling chemical processes using instrumental analysis methods significantly contributes to product quality, effective energy and raw material use, environmental performance, safety, and the overall plant profitability. Automated online process analyzer systems provide a real-time view of a process and help users make rapid adjustments that ensure better process control.

Analyzer systems can be relatively simple, such as a system that monitors moisture in a single hydrocarbon gas stream, or complex, such as an extensive multi-stream system that monitors process fluid composition at numerous points in the process. In either case, sampling systems are required to extract, collect, and possibly precondition a sample; transport the sample to the analyzer; properly condition it for introduction into the analyzer; and dispose of spent samples or return them to the process line.

Such complex systems, an amalgamation of valves, pressure regulators, and other fluid control devices, can vary considerably depending on the fluid being analyzed, the analytes, the point in the process at which the analysis occurs, the process conditions, and even the location in the plant where the analysis takes place.

Sampling System Improvements

Over the past two decades, analytical devices have become more capable and reliable, and the computers and software that drive and operate the systems have become more sophisticated, powerful, and user-friendly. Meanwhile, however, there has been very little change in the analyzer sampling system’s basic design even though they cause up to 80 percent of the problems associated with process analyzer systems.

As the capabilities of process analysis continue to develop and improve, the variety of measurements that can be taken has increased. Now the industry’s goal is to improve the performance of analyzer systems, reduce the cost to design, build, and install the systems, and reduce the operating and maintenance costs. To meet these goals, sampling systems will have to become miniature, modular, and intelligent.

Modular Design Moves to the Forefront

The Center for Process Analytical Chemistry (CPAC), a joint industry-academic research consortium located at the University of Washington, has moved forward with a New Sampling/Sensor Initiative (NeSSI). The purpose of the Initiative is to “facilitate the state-of-the-art evaluation and ongoing development of the next generation modular sampling system designs.”

A key element in the modularization strategy is open architecture. As part of NeSSI, CPAC asked various process analytical chemistry instrumentation suppliers and users to submit drawings of six new system designs that ranged from a relatively simple system to a complex eight-stream system.

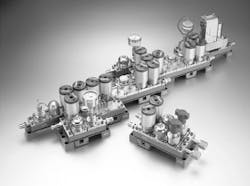

In response, Swagelok developed design concepts for all six systems using modular technology originally developed for specialty gas handling systems. One of the six systems, called “Measurement of ppm H2O and O2 in a High-Purity Hydrocarbon Stream” (Figure 1), demonstrated that the modular concept was feasible and practical.

Figure 1. One of the six systems Swagelok built to demonstrate that the modular concept is feasible.

This single-sample stream system was built with the fluid distribution components used in semiconductor gas handling systems just as proof-of-concept. An instrument air supply to purge the sensors and a nitrogen gas supply to calibrate individual sensors (zero gas) are manifolded into the system at appropriate points. The complete system measures 24.6 cm. (9.7 inches) wide by 75.2 cm (29.6 inches) long by 19 cm (7.5 inches) high, which is considerably smaller than panels and enclosures of traditional design.

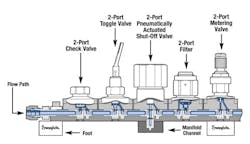

The modular technology that demonstrates the concept uses small flow components positioned in a substrate channel. All of the components were redesigned and/or reconfigured for application in process analyzer sample systems. Ports located side-by-side in the channel represent functional flow component inlet and outlet ports. For example, Figure 2 shows valves, regulators, or filters that will be surface-mounted on the substrate channel using four bolts each.

Figure 2. The modular technology used to demonstrate the concept in Figure 1 reconfigured for process analyzer sample systems.

Sequential flow components define the flow path through the system (Fig. 3). At points where different sample streams, purge gasses, flushing solutions, or calibration and/or validation fluids are to be introduced, manifolding is made possible by using a drop-down flow component that allows the main flow path to be connected to these other fluid streams.

Figure 3. Sequential flow components define the flow path through the system.

Modular Approach Yields Advantages

The modular approach to sampling systems offers many advantages:

- Development, lay-out time, and costs are reduced through the use of tools, such as Swagelok’s Configurator software. By reducing the size, weight, and footprint, it is easier to couple the sample system to dedicated field-mounted analyzers and place them at the sample point, reducing the need for long, heated sample transport lines;

- A small, modular sample system has less internal surface area than a traditional system, reducing the amount of material adsorption from the fluid;

- The system’s internal volume is also reduced, making it easier to purge or flush the system and conserve expensive analyzer fluids;

- The system is easier to assemble and installation only requires a few connections;

- Because the footprints are small, the work can likely be done on a bench rather than on a rack;

- Maintenance is easier because all the functional components are surface-mounted. Any component can be accessed from the top and taken out of the system by removing only four bolts; and

- Individual flow components in the substrate channel may be replaced by removing two functional components, inserting the specific flow component, and reassembling.

Different manufacturers offer different approaches to the substrate design. One offers substrates manufactured specifically for a given application that are comprised of substrate blocks and weldments. These blocks and weldments together form a unique flow path through the system.

Some manufacturers offer substrates consisting of individual blocks that, when bolted together longitudinally, form the flow path. Although face seals are required between each substrate block, no face seals, bolts or welding are required to construct the substrate assembly.

Real-time online analysis requires sample systems to be automated and integrated into the overall plant operating system. NeSSI Generation I systems resolve the physical issues of modularity by applying surface-mount functional components and control solutions. They use commercially available I/O-based control solutions and functional components are connected to a controller through I/O modules. The signals are conventional 4-20 mA and communications are point-to-point and one-way, accommodating only one device per wire.

The Next Phase: Intelligent Control

CPAC is now developing NeSSI Generation II to address the connectivity and communications issues that will lead to intelligent control of these sample systems. These systems promised to be compact and will include smart pressure, temperature, and flow sensors, smart valves with built-in electric-to-pneumatic actuators, multi-drop sensor bus communications that may be wireless, and Sensor Actuator Manager (SAM) to provide control and connectivity to the sample system.

CPAC expects NeSSI Generation II to address the connectivity and communications issues involved in intelligent control of sample systems. These systems promised to be compact and will include smart pressure, temperature, and flow sensors, smart valves with built-in electric-to-pneumatic actuators, multi-drop sensor bus communications that may be wireless, and Sensor Actuator Manager (SAM) to provide control and connectivity to the sample system.

CPAC expects NeSSI Generation II will use field bus-based control architecture with intelligence residing on the functional device. Ultimately, though, communication will have to be two-way so these devices will be able to talk to each other through the SAM.

Conclusion

Early adopters of compact modular sample system technology suggest that designing, building, and installing systems like the NeSSI Generation I can yield the cost savings anticipated. Now it’s up to operational testing and maintenance considerations to determine exactly what kinds of savings can be achieved.

As market manager, analytical instrumentation, Doug is responsible for leading the development of products and services that meet the needs of the analytical instrumentation industry. His duties include completing market research, evaluating competitive positions, justifying new projects, training distributor and sales associates, and conducting customer tours.

During his 13 years with Swagelok Company, Doug has held a variety of positions, including manufacturing engineer, shop supervisor, design engineer, and project manager in the new product development department.

Doug holds a bachelor of science degree in mechanical engineering from Case Western Reserve University and an M.B.A. from Kent State University. He also holds project management professional certification through Project Management Institute.