Educating people about the value of maintenance is more important than ever. I wish the companies now cutting resources on a daily basis knew that maintenance actually can save them money.

For years, the engineering and maintenance community has complained that the general public has no clue about what we do; how interesting and sophisticated our work is; and how much commitment it takes to perform and provide professional maintenance and reliability. With insurance liabilities, our limited available time and plant security issues, we can’t show them much. How can we visually raise the profile of maintenance in the eyes of the public?

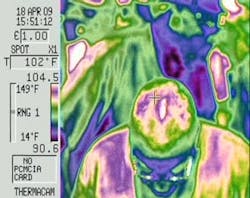

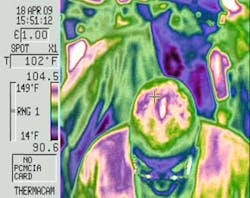

Maintenance Evangelist Joel Leonard demonstrates

how to use infrared to measure heat at the Asheboro,

N.C., chili cook-off.

On April 18, I took on that challenge by hosting a Hot Head Contest, performed in front more than 600 people in a town that, last summer, Forbes magazine deemed to be fourth-fastest dying community in the United States. Below is the recap we received from Ralph “Pete” Peters, president of the Maintenance Excellence Institute, on this event and what he heard during the competition.

“We informed the contestants that they would be assuming a risk and can’t hold anyone associated with the event liable for their decision to participate,” Peters reports. With that said, 18 brave/stupid (fine line between them) vied for the opportunity to sample the chili and take home a $250 grill provided by Lowes and consolation prizes provided Grainger Industrial Supply.

Chili cook-offs come and go, but this one was a special event. First, the audience learned about ‘hotness.’ They saw a sauce so hot that medics would be needed if they sampled it. They learned how to measure the temperature of one’s head after consuming the hot sauce of their choice. You see, this head-warming event used a Stockton Infrared thermographic imager to determine the winner.

So, what’s so special about people eating bagel bits that were dipped into hot, hotter and the hottest hot sauce ever made? The great throng of Asheboro participants learned a great deal about a valuable predictive maintenance technology. The brave Hot Head contestants tried to exhibit as much heat as possible. One intrepid young man, who registered a forehead temperature of 121°F, made it to the top three. But, he stopped eating the ‘hot stuff’ and waited for the final round. Then, when temperature counted, he dropped to second place with only 105°F.

In addition to the crowd’s excitement, something special happened. As a contest judge, I could hear the audience making comments such as, “Are you kidding me! Maintenance people can use this thing in a plant?” The lady beside him said, “Yeah, man. You can even use it to check roofs for water seepage and leakage down walls. But you gotta be up in a pine tree or riding in a helicopter or plane to take those pictures.”

Finally, I explained the importance of maintenance using one important tool: thermography, or infrared scanning. Maintenance has gone well beyond the simple bag of hammers, pliers, screwdrivers and adjustable wrenches. The Asheboro crowd learned more about mission-essential maintenance, hot sauces and the Scoville scale that quantifies the hotness in ‘hot stuff.’ Everyone had fun; even the contestants who were still on fire after a water-cooler full of Gatorade was dumped on the Hot Head winner — the ceremonial acknowledgement of his red-hot victory.

When the winner loaded his new grill onto his pick-up truck, Karma struck. While he was calling his father to boast about his winnings, a bird flew over and dumped a fresh dose of bad news on his head. Check out www.asheborochilicookoff.com for pictures and more details.

We need to raise our profile and develop more maintenance and reliability pros. We need to teach executives why they should not cut headcounts. Otherwise, our livelihoods will continue to be dumped on. If you know of others who are working to break the silos with innovative approaches, please share this story, because it might inspire others to pitch in.

E-mail Contributing Editor Joel Leonard at [email protected].