Develop workers with time saved by top performers

I was involved in a leadership situation many years ago as a member of the senior leadership team. A middle manager and line supervisor were struggling with the performance of a person who was filling a lead technician role; we’ll call him Ralph. Our organization was responsible for the maintenance and repair of a complex control and monitoring system. Ralph had been sent to an advanced school to be trained on the system. He passed the course and his training was documented. Earning the certificate for this training was a contributing factor for Ralph being promoted to his position as lead technician.

[pullquote]In the two or three years following the promotion, Ralph had rarely been asked to use those skills because we relied on other technicians who had since left or been promoted.

Crunch time came when Ralph was asked to step up and take the lead on troubleshooting the control and monitoring system at a particularly important time. He failed miserably. We had to bring in others, which was costly in terms of money and our team’s reputation.

The middle manager and the line supervisor were angry and wanted to demote Ralph. In most other respects, Ralph was what I would call a “decent performer”. He wasn’t great, but in other respects he did a reasonably good job.

It would have been easy to allow Ralph’s demotion to occur but, as I’ve said in past articles, a leader’s first obligation is to determine whether the low performance level is the result of inability or unwillingness. We needed to work with the guy; after all, our organization didn’t require him to use the skills for two or three years. The manager and supervisor protested. My response to them was a series of three questions:

Do you have poor or weak performers who require more of your time than the good or strong performers? The answer was yes.

Do you have strong performers who do more than you ask of them and who don’t require much of your time? The answer was also yes.

Do you recognize that it’s your job to develop your people and that your strong performers provide you with the time to focus on the weak performers? This time, the answer was a blank stare.

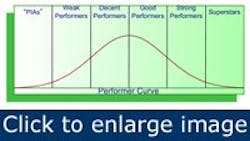

The greatest numbers of people are decent-to-good performers (see figure). The superstars and PIAs (Pain-In-the-After-parts; to be politically correct) are fewest in number. The farther we move from the center to the right or left, the larger the time dividend available or time reinvestment required.

Superstars need no supervision. Strong performers and good performers often require no more than positive recognition and a little more excitement or challenge to their work. People who perform on the right side of the bell curve provide managers and supervisors with a net gain in the time available to manage a team.

As we move from the center of the bell curve to the left, we need to allocate progressively more time per person. We need to provide guidance, coaching and holding people accountable. Punitive HR policies take too much time and effort, but are designed to encourage unwilling people to get with the program, or get gone.

Most of us are human (one guy I worked for causes me to say “most”). We accept the benefits of the good to superstar performers as something we expect from everyone. However, the world is made up of many personalities and leaders need to use their time dividend from the positive performers to reinvest in the teams lesser performers. It’s in our job description.

Tom Moriarty, P.E., CMRP, is president of Alidade MER Inc. Contact him at [email protected] and (321) 773-3356.