Most people, especially those from a family with a history of a particular illness, schedule regular checkups throughout the year. Knowing which weaknesses reside in a person’s system allows taking measures to prevent a serious and possibly long-lasting human downtime. Even if something goes wrong, a well-documented patient history might mean the difference between life and death.

In many industries, managers work hard to reduce equipment downtime. What better way of doing this than by subjecting plant equipment, just like people, to regular checkups. Some equipment might be prone to more problems than others and will require greater attention. To determine what must be done to ensure that a physical asset continues to do what its users want it to do in its present operating environment, managers use reliability-centered maintenance (RCM), which helps to define a complete maintenance regimen and is a process that can form a vital part of a company’s preventive maintenance program.

RCM is a term that’s widely used in industry. However, it isn’t always well understood. It requires plant personnel to monitor, assess, predict, and generally understand how physical assets work. This identifies certain failure modes, thereby enabling appropriate maintenance tasks to be established. RCM is described as “a systematic approach to defining a routine maintenance program composed of cost-effective tasks that preserve important functions.”

RCM history

The RCM process has its roots in commercial aviation, and the acronym was coined in a 1978 report titled “Reliability Centered Maintenance,” which was authored by F. Stanley Nowlan and Howard Heap — two employees of United Airlines — and sponsored by the U.S. Department of Defense (DOD). This report embodied the latest technologies commercial aviation developed and used over a period of time dating back to the early 1960s.

[pullquote]The commercial airline industry worked closely with the Federal Aviation Administration (FAA) to establish a well-structured RCM process, which was necessary to meet the FAA requirements of ensuring more reliable commercial aircraft and better safety performance. Until then, the performance records of the commercial airline industry were poor. However, their involvement in developing the process demonstrated a clear understanding of the consequences of not using a sound approach, such as RCM. These consequences included unreliable equipment with the possibility of a catastrophic failure while in the air, resulting in multiple fatalities.

The results of their efforts are evidenced by the fact that commercial airline travel is now much safer than driving on a public road. The commercial airline industry continues to use the RCM process to ensure the continued safe and reliable aircraft performance.

Verifying a true RCM process

Since the late 1980s and early 1990s, many companies have been using the RCM process for their own assets. In answer to this demand, a number of RCM derivatives, each claiming to be as good as or better than the original, have materialized. Unfortunately, some have modified the process to such an extent that it no longer provides the same benefits as the original.

As a result and in an effort to qualify a process as an RCM process, the Society of Automotive Engineers (SAE) developed and published a standard that would prove a process was truly an RCM process. This document, SAE standard JA 1011, was published in 1999 and is now used by many companies. It requires a candidate RCM process to satisfactorily answer seven questions in sequential order. In addition, it must provide the basis for answering these questions satisfactorily.

The main players

The classical RCM process begins with a review of the individuals involved in the analysis. To conduct an RCM analysis effectively, the participants must know about the system or equipment under review. In other words, participants such as operators and those who maintain the system must work with the system on a daily or frequent basis. In addition, front-line supervision in both the operating and maintenance are also involved. Others, such as OEM representatives and subject matter experts, are brought into the analysis as needed. The subject matter experts might not have in-depth knowledge of the system but are typically experts in areas such as engineering, safety and quality management. A key player is the RCM facilitator who orchestrates the group during the analysis.

The RCM process

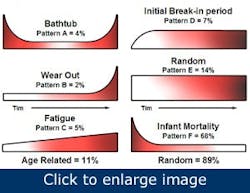

The cornerstone of the RCM process is understanding that there are six failure patterns to be considered when defining maintenance strategies. The commercial airline’s extensive analysis of failures determined that 20% of equipment failures are a result of time-based failure patterns (as seen in the three graphs to the left in Figure 1), while the remaining 80% aren’t time-dependent (right three graphs). Even though the majority of maintenance work was performed after a set number of run hours — where typically 85% of components were taken through overhauls — the failure question wasn’t solved because the majority of failures weren’t time-dependent. As a result, infant mortality was introduced as components were overhauled, leading to the realization that condition-based maintenance was the best solution to asset failures.

(Figure 1) Failure patterns: The commercial airline industry determined that only 20% of equipment failures are a result of time-based failure patterns.

The RCM process begins with an understanding of how a system is being used, the system’s operating context . This is followed by the seven questions:

- What are the functions and desired standards of performance?

- In what ways can it fail to fulfill these functions?

- What can cause each functional failure?

- What happens when a failure occurs?

- In what way does each failure matter?

- What should be done to predict or prevent the failure?

- What should be done if a suitable proactive task can’t be found?

The RCM process — analysis meetings

A typical RCM analysis meeting lasts four hours, and five to 15 meetings are required to complete an analysis. To be more specific, conducting an RCM analysis requires a significant commitment of resources. To illustrate this point, consider an RCM analysis of a pump station, where there are two identical 50-hp centrifugal pumps, one duty and one standby pump. A typical analysis requires about seven days. In performing such an analysis, the functions, functional failures, and likely failure modes that could cause some of the system functions to fail are reviewed. Some examples of function statements for the pump station include:

- To supply oil to the generator bearings and gearbox at a minimum pressure of 50 psi and temperature between 15°C and 50°C

- To contain the oil

- To be capable of supplying oil to the generator bearings and gearbox in the event the duty pump fails

- To be capable of redirecting the oil back to the suction line in the event the oil pressure exceeds 90 psi

- To maintain the oil at a temperature below 50°C

However, time is needed to identify the functions and functional failures, followed by a listing of the likely failure modes — for this example there could be as many as 100 failure modes.

Why perform an RCM analysis

An RCM analysis requires resource and time commitments if it’s to be conducted properly. If a typical pump RCM analysis needs about seven days to complete, the time and resources required to analyze all on-site systems and equipment is enormous. So, this question centers on whether the benefits are really worth the effort.

One way of answering it is to ask if the failure of any system or equipment can result in either serious injury to people or a breach of environmental regulation. Failures that have safety consequences are simply not an option. If there’s a risk, no matter how small, the RCM process should certainly be considered. Even systems or equipment covered by protective devices or controls should be considered for RCM analysis because the RCM process can then verify if these devices or controls will eliminate or mitigate the consequences.

Benefits of performing RCM analysis

There are a number of benefits to performing an RCM analysis.

- Create a comprehensive equipment maintenance program; in this program, maintenance strategies with defined tasks and frequency are evaluated against technical feasibility and cost-effectiveness

- Identify of physical and procedural redesigns

- Increase maintenance cost-effectiveness

- Identify assets that can run to failure

- Identify key training opportunities

- Improve process knowledge across an organization

- Generate troubleshooting guidelines

An additional benefit is documenting the knowledge and experience gained by those who participated in the process. This in itself could be a means of capturing information from those who might be retiring but whose knowledge remains undocumented.

Preventive maintenance component

The RCM process can be a vital part of a preventive maintenance program. In addition, it can provide participants with a better understanding of how critical assets operate and an understanding of the tasks needed to ensure reliability and mitigate failure consequences associated with the safety of people and breach of environmental regulations.