Discover the financial benefits of value-driven maintenance

In brief:

- The value of maintenance comes from delivering maximum availability at minimum cost.

- Maintenance managers must show where there’s potential for value within the maintenance organization and should focus on the value driver with the highest value potential.

- Managing by value is not just a must; it is the only way to discover the true significance of maintenance.

What is actually the added value of maintenance? That question is frequently heard in boardrooms the world over. Even though maintenance is often critically important, few maintenance managers are able to answer the question convincingly, especially when they are asked to express the benefits in terms of economic value added or shareholder value — the language increasingly being spoken in boardrooms all over the world.

The definition that value is equal to the sum of all future cash flows, discounted to today is translatable into the following formula:

PV = ∑ {CFt /(1+r)t}

Where:

PV = value (present value)

CFt = future free cash flow in year t (cash flow)

r = discount rate

To calculate the value of maintenance, this formula can be applied in the following way:

PVmaintenance = ∑ {FSHE,t x (CFAU,t + CFCC,t + CFRA,t + CFSHE,t) / (1+r)t}

Where:

PVmaintenance = value of maintenance

FSHE,t = SHE factor in year t (% of compliance with SHE regulations)

CFAU,t = future free cash flow in year t from asset utilization

CFCC,t = future free cash flow in year t from cost control

CFRA,t = future free cash flow in year t from resource allocation

CFSHE,t = future free cash flow in year t from SHE

r = discount rate

“Value driven maintenance” (VDM) builds a bridge between traditional maintenance philosophies and managing by economic added value. Not only does VDM simplify the boardroom discussion, it also shows that, far from being a cost center, maintenance can create significant economic value, improving the overall business performance.

What is value?

Before you can manage by economic added value, you have to understand value, which is the sum of all future free cash flows, discounted to today.

This sounds impressive, but what precisely does it mean? Let’s start by looking at the first part of the definition. A cash flow is the difference between income and expenditure. This is not the same as the difference between revenues and costs, because that’s an item that can be greatly influenced by accounting practices. Some companies use highly creative lease, depreciation, and reservation techniques to keep their book profits artificially high or low. This doesn’t always contribute to the economic value of the company.

The second part of the definition stems from the knowledge that the value of a cash flow is related to time. One dollar is worth more today than the same dollar will be next year. This is because you can deposit a dollar at the bank today and use it to generate income over a period of one year. Therefore, we have to adjust future cash flows.

Value of maintenance

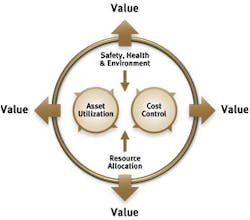

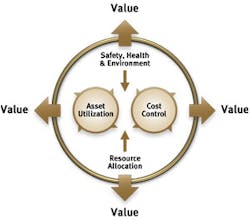

Figure 1. VDM is designed to provide answers to identify the potential of the four value drivers in maintenance and enabling those drivers to be managed.

A maintenance manager is likely to acknowledge this theoretical approach, but be more interested in the practical application of it. The value of maintenance comes from delivering maximum availability at minimum cost. While this is true in theory, it’s of little help in day-to-day operations. This is because of priorities. Do you want to reduce costs or increase uptime? Is a 1% increase of uptime just as valuable as a 1% reduction of costs? How do you determine the value of safety? VDM is designed to provide answers to those questions by identifying the value potential of the four value drivers in maintenance and enabling those drivers to be managed (Figure 1).

Maintenance managers are constantly balancing higher machine availability (asset utilization) with lower maintenance costs (cost control). They must take into account the growing body of laws and regulations covering safety, health, and environment. To make everything work, they need to use the right technicians, spare parts, knowledge and contractors (resource allocation).

Say a paper factory produces 1,000,000 kg of high-quality paper each year, with 50% asset utilization. The price of each kg of paper is $10, with a profit margin of 15%. The factory’s annual maintenance costs come to $500,000 and it keeps $300,000 of spare parts in stock. The annual management costs for the inventory of spare parts (personnel, space, insurance) equals 15% of the value of the stocks. The maintenance concept is of a highly corrective nature, with a SHE factor of 70%.

Based on a thorough reliability study, the reliability engineer has recommended giving the maintenance concept a strongly preventive nature. Each week an extra one-day inspection will be carried out by two technicians (mechanical and electrical). This will increase annual maintenance costs by 52 x 2 x $500 = $52,000.

Given the preventive nature of maintenance, the reliability engineer expects to increase asset utilization to 55% and to reduce the inventory of spare parts to $250,000. The new maintenance concept will not influence the SHE factor.

This makes the value of this improvement proposal:

FSHE,t = 70%

CFAU,t = 5% x 1,000,000 x 15% x 10 = $75,000

CFCC,t = $-52,000

CFRA,t = 15% x 50,000 = $7,500

CFSHE,t = 0

r = 16% (internally determined discount factor)

PVmaintenance, t = 0->10 = ∑ { 0.7 x (75,000 – 52,000 + 7,500 ) / (1 + 0.16)t } = $103,189

PVmaintenance is greater than zero, so there is an increase in value and the recommendation should be adopted.

For all four value drivers, maintenance can help to increase a company’s economic value. In a market where there is more demand than supply, greater machine availability results in more products, more income, and thus higher value. On the other hand, lower maintenance costs produce higher value by avoiding expenditure. The same applies to resource allocation. One example is a technical storeroom. Smarter inventory management of spare parts can enormously increase value for a company.

Similarly, the safety, health, and environment (SHE) factor affects value. SHE accidents tend to necessitate substantial expenditure, with resulting negative cash flows. Damage caused to personnel, environment, and image, for example, will increase expenditure. An even greater danger is loss of the license to operate because of inability to comply with SHE legislation. No license to operate means no production and no income.

Value potential

Maintenance managers must show where there’s potential for value within the maintenance organization and should focus on the value driver with the highest value potential. VDM can provide calculation models and industry-specific benchmarks to determine the dominant value driver within the maintenance organization (see Value Destruction at BP at the bottom of the article). Note that the result of the calculation of value will differ markedly depending on the industry involved. For example, in the European industry for construction and building material, there’s currently less demand than supply, and prices are under considerable pressure. The value potential lies mainly in controlling costs and the smarter deployment of people and resources. In most pharmaceutical companies, the situation is the other way around. Demand for medicine continues to grow, but the technical availability of the production process is relatively low. This matter is obviously receiving attention. The SHE factor here is becoming more important with the growing role of the U.S. Food and Drug Administration in the global pharmaceutical industry.

Value and time

Figure 2. The maintenance manager from Volvo’s largest manufacturing site was able to reduce the maintenance budget by 50%, without jeopardizing uptime or safety of the plant.

The next example shows that value depends not only on the industry concerned, but also on time. Around 2007, the automotive industry was one of the first industries that experienced the financial crisis. The demand for cars declined dramatically, and automotive companies needed to change their strategies quickly, from top floor to shop floor, including maintenance.

Volvo Cars, the Swedish car manufacturer with plants in Sweden and Belgium, after years of focusing on asset utilization as its dominant value driver, suddenly found cost control had become number one. As its TPM-based maintenance strategy was only aiming at plant uptime, Volvo Cars implemented VDM to optimize the maintenance costs. Three years later, in 2010, the maintenance manager from Torslanda, Sweden, Volvo’s largest manufacturing site, announced that he’d been able to reduce the maintenance budget by 50%, without jeopardizing uptime or safety of the plant (Figure 2). The lower cost levels helped Volvo Cars to survive the financial crisis and be ready for the future. Once the demand for cars grows again, Volvo will need to adjust the maintenance strategy, focusing on asset utilization again. And so the dominant value driver, and thus the maintenance strategy, changes over time as a result of the market situation.

Value and competencies

Figure 3. Once the dominant value driver and its value potential have been identified, the maintenance function must be organized accordingly.

Once the dominant value driver and its value potential have been identified, the maintenance function must be organized accordingly. Which competencies are important (Figure 3)? Take the example of a plant in construction and building materials. The market situation means that most value is currently achievable by controlling costs. So the right-hand value circle must be configured from maintenance budgeting to cost analysis. The opposite applies to the pharmaceutical industry. There, the left-hand value circle must be organized from equipment performance planning to loss analysis. Interestingly, both value circles include the competencies of reliability engineering, planning and preparation, and maintenance execution. These competencies are the links between the four value drivers, including SHE management, and thus form the heart of VDM. On the bottom of the model, you find the competencies related to the four maintenance resources: MRO supply chain management (spare parts), service supply chain management (services from contractors), skill and tool management (internal work force), and equipment knowledge management (drawings and manuals).

Value and best practices

Total productive maintenance (TPM) enjoys a reputation mainly as the best practice for registering, analyzing, and improving production losses (asset utilization). In contrast, asset based costing (ABC) is a proven best practice for properly controlling maintenance costs. Using these best practices, a technical department can quickly become a professional maintenance organization that adds value to the overall business performance.

Managing by value is not just a must; it is the only way to discover the true significance of maintenance. VDM makes maintenance more than a cost center because it contributes in various ways to a company’s economic prosperity. In fact, VDM confirms what maintenance managers already thought and gives them the proof to show it to senior management.

To learn more about value-driven maintenance, read Maintenance business experience

Value Destruction at BP

The 2010 Deepwater Horizon oil spill in the Gulf of Mexico is a striking example of how an individual asset can influence the shareholder value of an entire company. On April 20, 2010, BP’s oil platform exploded and caused one of the biggest environmental disasters of our time. Investigation has shown that one of the main reasons of this explosion was a failing safety valve, which was manufactured at low costs and wasn’t maintained as being a highly critical item. This accident caused a 50% reduction of BP’s shareholder value within three months. This can be explained by three of the four value drivers.

Immense repair costs (cost control): On Aug. 9, 2010, BP announced that the repair of the oil spill had cost the company $6.1 billion. In addition, BP recently announced they’ve paid another $7.8 billion to creditors, especially fishermen.

Reduction of income (asset utilization): The exploded platform was not able to produce any longer.

Risk of losing license to operate (safety, health, and environment): This safety incident raised numerous questions and brought attention to governmental bodies about the safety procedures at BP, not only for the Deepwater Horizon, but for all BP platforms. The uncertainty about BP’s license to operate resulted in devaluation on the stock markets.