Ask the Experts: Why do industrial motors trip on startup?

Key takeaways

- Improper starting methods or VFD tuning can cause high inrush currents, leading motors to trip on startup.

- The motor’s kVA code directly impacts starting current—ensure the electrical system can handle the load.

- Always verify wiring, starter settings, and line voltage; small electrical issues often cause startup failures.

- Mechanical overloads, such as blocked conveyors or damaged bearings, can trip motors just as easily as electrical faults.

In this Ask the Experts feature, technical service specialists from EASA tackle topics related to electric motor application, operation, maintenance and repair. The Electrical Apparatus Service Association (EASA) is an international trade association of more than 1,700 firms in nearly 70 countries that sell and service electromechanical apparatus. For more information, visit easa.com.

This month’s question: What can cause an electric motor to trip its overload protection device during startup?

Mike Howell, PE (Technical Support Specialist, EASA)

When a new AC motor trips its overload protection during startup, several factors could be at play, particularly related to starting methods and kVA code.

Starting methods. The starting method used can significantly impact the motor's performance. Common starting methods include direct-on-line (DOL), star-delta, and soft starters. DOL starters apply full voltage to the motor, resulting in high inrush currents that can cause the motor to trip if the electrical system cannot handle the surge. Star-delta starters reduce the initial voltage, but improper switching or timing can still lead to tripping. Soft starters gradually increase the voltage, minimizing inrush current; however, if these starters are not correctly configured, they can also cause issues. If the motor is inverter-fed from a variable-frequency drive (VFD), inadequate drive tuning could also prevent a successful start.

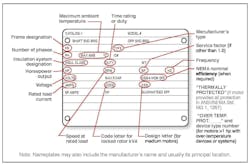

Motor kVA code. Another critical factor is the kVA code on the motor nameplate. Motors with higher kVA ratings (e.g., H vs. E) have higher starting (inrush/locked rotor) currents relative to horsepower that can exceed the capacity of the electrical system, leading to tripping. To prevent this, it is essential to ensure that the electrical system rating is adequate for the motor's kVA code.

Other issues. Besides an inadequate power supply, other potential causes for tripping on startup include incorrect wiring, faulty components, or mechanical problems such as excessive load or binding in the driven equipment (see Figure 1). Proper installation, configuration, and maintenance are all crucial to avoid startup tripping and ensure reliable motor operation.

Chuck Yung (Senior Technical Support Specialist, EASA)

Inrush (starting) current. If a recently replaced motor trips during starting, begin troubleshooting by comparing its nameplate KVA code letter with that of the replaced motor (see Figure 2). The further along a code letter is in the alphabet, the higher the motor's inrush current. For example, a motor with code letter H has a higher inrush current than one with code letter E. Higher efficiency motors typically permit more inrush current. If that’s the culprit, adjust the trip settings of the starter to accommodate the increase.

NEMA kVA code letters represent kVA/hp multiplier ranges for motor starting current formulas (see NEMA Table 10.37.2 below). Starting current is referred to as locked-rotor amps (LRA) in the following formulas:

LRA = (kVA/hp value x Motor hp x 1000) / Voltage [1-phase motors]

LRA = (kVA/hp value x Motor hp x 1000) / (Voltage x 1.732) [3-phase motors]

NEMA CODE LETTERS FOR LOCKED-ROTOR KVA

AT FULL VOLTAGE AND RATED FREQUENCY

Letter designation kVA per horsepower* Letter designation kVA per horsepower*

A 0 - 3.15 K 8.0 - 9.0

B 3.15 - 3.55 L 9.0 - 10.0

C 3.55 - 4 .0 M 10.0 - 11.2

D 4.0 - 4.5 N 11.2 - 12.5

E 4.5 - 5.0 P 12.5 - 14.0

F 5.0 - 5.6 R 14.0 - 16.0

G 5.6 - 6.3 S 16.0 - 18.0

H 6.3 - 7.1 T 18.0 - 20.0

J 7.1 - 8.0 U 20.0 - 22.4

V 22.4 and up

* Locked kVA per horsepower range includes the lower figure up to, but not including, the higher figure. For example, 3.14 is designated by letter A and 3.15 by letter B. (Ref.: ANSI/NEMA Stds. MG 00001-2024, 10.37.2.)

Starter settings. A good second thing to check is the starter itself. Like most things electrical, settings may change over time, due to vibration or other factors.

Line voltage. Another possible cause of tripping on startup is elevated line voltage, possibly originating with the utility. For example, in some areas, nominal 480-V service can exceed 500 V. This condition may be seasonal or related to fluctuating power demands, the weather, bus stiffness, or distance from a substation.

Billy Higgs (Technical Support Specialist, EASA)

When a new or recently repaired motor trips the circuit, simple troubleshooting steps can often resolve the issue quickly and with minimal effort.

Simple troubleshooting steps

- First, review the commissioning documents to verify that the replacement motor is the correct hp/kW rating.

- Also, ensure that an insulation resistance test was conducted immediately before installation, confirming that the motor has not absorbed moisture. If available, review the motor vendor’s full-voltage test run report to verify that both current and voltage are balanced.

- Next, make sure the motor’s external connection is correct for its voltage rating with no mixed-up cables.

- Then carefully inspect the interior of the junction box to identify and reposition any leads or connections that could cause an easy-to-miss ground failure at the enclosure.

Electrical system checks

- If there are fuses in the circuit, make sure they are sized properly and test correctly.

- Verify that no single-phase, phase-loss, voltage surge or unbalanced voltage conditions have occurred.

- Check the wiring system to confirm that all damage from previous motor failures has been repaired properly. For example, have shorted line leads been corrected?

Other issues

- Determine if the driven equipment is mechanically overloading the motor. For example, if a blocked shredder or conveyor caused the previous failure, confirm that the obstruction has been removed.

- If the motor has an anti-reversing ratchet, make sure its rotation is correct (see Figure 3).

- Ensure that the ambient temperature does not exceed the maximum recommended on the motor nameplate.