Ask the Experts: Best practices for storing spare electric motors in industrial facilities

Key takeaways

- Rotate motor shafts monthly to prevent bearing damage and rotor sag in stored spares.

- Maintain winding temps 10°C above dewpoint to avoid moisture damage during long-term storage.

- Document every storage action—like shaft rotations and insulation tests—for future traceability.

- Use rust inhibitors and dehumidifiers to protect motors stored in humid or non-climate-controlled areas.

In this Ask the Experts feature, technical service specialists from EASA tackle topics related to electric motor application, operation, maintenance and repair. EASA is an international trade association of more than 1,700 firms in nearly 70 countries that sell and service electromechanical apparatus. For more information, visit easa.com.

This month’s question: What are some best practices for storing electric motors as “spares” for critical applications?

Chuck Yung (Senior Technical Support Specialist, EASA)

When storing spare motors for future use, a primary concern is to prevent corrosion of the uncoated surfaces, especially bearings. And for motors with a rotor weighing about 2,000 lb or more, avoiding shaft sag is crucial. It’s also important to keep the windings dry and prevent infestation of rodents and other pests.

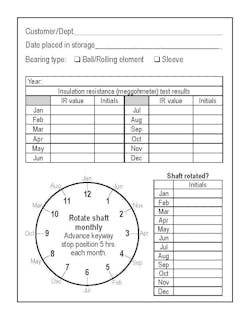

Monthly shaft rotation. An easy way to handle the first two concerns is to spin the shaft several revolutions each month. This redistributes lubricant on shaft and bearing surfaces and repositions the weight of heavy rotors. When maintaining multiple motors in storage, a simple way to accomplish this task consistently is to place all shaft keyways at the 12 o’clock position to start. Each month, rotate the shafts several revolutions, advancing the stopping point 5 hours on the clock face–e.g., 12:00 in January, 5:00 in February, 10:00 in March, and so on (see Figure 1).

This 5-hour increment system ensures even distribution of rotor weight over time, preventing permanent bowing in heavy rotors. It also repositions the contact points of rolling element bearings along inner and outer races, reducing the risk of ambient vibration damage. Additionally, it provides a quick visual check for maintenance completion–misaligned shafts indicate missed rotations.

Shaft sag is a real and costly issue. I recently received a call about a brand new 2,500 hp motor that had been in climate-controlled storage for several years without periodic shaft rotation. Before commissioning it, the owner decided to have the bearings replaced “just to be safe” and discovered 0.020” runout mid-rotor. Monthly shaft rotation would have saved the cost of two bearings and a new shaft.

Climate control. Storing electrical equipment in a climate-controlled environment with the winding temperature 10°C above the dewpoint keeps the windings dry while minimizing rust. Rather than heating and air conditioning, a dehumidifier is more effective and less costly to operate.

Critter control. As for rodents and other pests, there are many options, including screens and covers. Just be sure to allow enough airflow to prevent condensation.

Mike Howell, PE (Technical Support Specialist, EASA)

Proper motor storage is essential to ensure reliable performance when motors are eventually placed into service.

General storage conditions. Ideally, motors should be stored indoors in a clean, dry, vibration-free environment. Store horizontal motors horizontally and vertical motors in stable vertical positions. If indoor storage is not possible, cover the motor with a tarp that allows enough air circulation to prevent condensation but is secure enough to keep out moisture and pests. Prevent rodents, birds, and insects from entering the motor, as they can damage winding insulation and block ventilation.

Long-term storage. If storing a motor more than a month or so, apply a rust inhibitor to exposed machined surfaces and, in humid environments, consider painting interior surfaces and using a topical fungicide on windings. Other long-term storage tactics include the following:

- Bearings. Grease-lubricated bearings should be fully packed with compatible grease, while oil-lubricated bearings must be filled with oil containing rust inhibitors after placement. Periodically check lubricants for moisture or contamination and replace as needed.

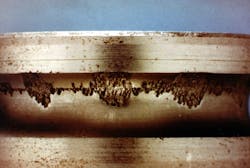

- Ambient vibration. Prolonged exposure to even low-magnitude vibration can damage bearings–e.g., false brinelling (see Figure 2). To prevent this, rotate the shaft monthly and store motors on vibration-isolating materials if necessary.

- Windings. Maintain winding integrity by keeping windings 5-10°C above ambient using space heaters or trickle heat and regularly record insulation resistance (IR) and polarization index (PI) values.

- Documentation. Keep a record of all storage and maintenance actions for future reference.

Billy Higgs (Technical Support Specialist, EASA)

Storage requirements vary according to machine type. For instance, maintenance procedures for storing a 3,000 hp sleeve-bearing machine differ significantly from those for a 300 hp low-voltage ball bearing motor or a 1,000 hp DC machine. Still, some general storage guidelines apply across all motor types.

Documentation. A common saying in quality management (QMS) circles is: “If you didn’t document it, you didn’t do it.” End users who value how their equipment is stored understand that maintaining accurate records of all storage-related activities supports equipment reliability and traceability. For example, for each motor you have in storage, you should document whether or not you rotated the shaft, and when. If you conduct an insulation resistance test, record the result, and the date it was performed. Make it a habit: Document every storage activity.

Humidity control. If you store motors in a high humidity area, consider applying a suitable rust inhibitor to unpainted or uncoated surfaces, such as shafts and bearing housings. If you require dehumidifiers in the storage facility, be sure to clearly communicate this to your storage vendor.

Internal space heaters. If a machine has space heaters, they can help prevent condensation inside a motor, both during storage and when it is idle for long periods in situ.

Machines with brushes. Brushes for DC machines, synchronous and wound rotor motors should be lifted during storage to prevent corrosion of the commutator and relieve spring pressure (see Figure 3).