How corrosion affects electric actuators, and what you can do to prevent it

Corrosion in electric actuators impacts performance, functionality, durability and safety if left unchecked. It can also increase maintenance costs, sap energy and impact the environment. To prevent corrosion in actuators, it is important to select materials suited for the operating environment, implement proper maintenance and inspection routines, and consider protective measures such as coatings, seals or enclosures to shield the actuator from environmental factors.

What causes corrosion?

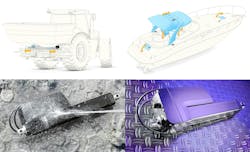

Extended exposure to moisture and humidity is the primary cause of corrosion in actuators (Figure 1). The in-out motion of the actuator shaft creates a negative internal pressure, which may require some kind of pressure relief function to prevent ingestion of moisture. The reaction to the metal surfaces and the water, facilitated by oxygen in the air, corrodes the metal. Actuators used in marine or coastal environments are even more susceptible to corrosion because the salt interacts with the metals.

Extreme temperatures, hot or cold, can also exacerbate the corrosion, particularly in the presence of high condensation or rapid temperature changes. Operating in hot environments adds wear to all components and challenges lubrication.

Exposure to other aggressive chemicals holds the potential for corrosion as well. Opening and closing valves in sewage treatment plants, dispensing fertilizer or applying pesticides are among the many actuator applications that can corrode motion control equipment that is not adequately protected.

Lastly, interaction with other environmental factors can deepen corrosion. Running diesel-fueled engines in humid, coastal regions, for example, not only adds greenhouse gases to the atmosphere but also contributes to corrosion, especially in unfiltered maritime applications.

Preventing corrosion

Controlling corrosion is a function of the primary material, coating, sealing, temperature control and adequate maintenance.

Materials and coatings

Stainless steel has excellent corrosion resistance, making it the primary choice for applications where exposure to moisture, chemicals or other corrosive substances is a concern. Stainless steel is an especially good choice where there is a risk of scratching or mechanical wear, as in actuator fixations, for example.

Anodized aluminum is a lighter and less expensive alternative to stainless steel. It is significantly harder with more wear and scratch resistance than untreated aluminum. Its dense, self-healing aluminum oxide layer resists wear and scratching, protecting the underlying aluminum from corrosion and oxidation. Anodized aluminum is, however, less corrosion resistant than stainless steel and not recommended for the harshest or most corrosive environments. Anodized aluminum does have better thermal conductivity than stainless steel, though, making it worthy of evaluation for intended high-temperature operations.

Nickel plating offers some corrosion resistance but is prone to scratching. Some actuator vendors are using corrosion-resistant plastics as well. Materials such as polyester, vinyl ester, epoxy resins, and thermoplastics like polyethylene and polyamide enable manufacturers to keep costs down while offering adequate protection in some cases. However, these materials are still not as protective, strong or durable as stainless steel.

To get the right balance of corrosion prevention, weight and cost, the actuator designer may combine materials, for example, using stainless steel for the front and rear fixations, and anodized aluminum for the outer cover profile. Screws holding assemblies together may also be coated with a protective layer to minimize fastener corrosion. This can be either a metal plating or an organic coating. Stainless steel fasteners are an option, but when higher strength is needed, stronger steel with a protective coating is often the best solution.

Sealing

Proper sealing counters corrosion by preventing exposure to chemicals, water, dust, and other potential intruders. Compliance means that the seals have been tested against different threats and that they can withstand long exposures and high-water pressures, including hundreds of hours of exposure to salt spray, dirt, dust, and water, as well as more aggressive substances such as fertilizers, acid, oil, grease and cleaning agents.

Most vendors will publish the ingress protection (IP) capabilities for their products. Level IP65 compliance indicates that the material is suitable for general operation and protects against dirt, dust, and water jets. The first number indicates the actuator is dust tight, and the second digit represents protection from sprayed liquids. IP66 adds increased protection from water pressure and water flow, including washdown with powerful water jets.

Levels IP67 and IP68 compliance indicate protection against dirt, dust, and immersion in water as well. IP67 can withstand submergence in up to one meter of water for up to 30 minutes, while IP68 can withstand deeper submergence for longer, but the exact specifications vary by vendor. However, neither IP67 nor IP68 compliance testing alone will provide IP66-level protection against high-flow water washdown.

Level IP69K indicates protection against elevated temperature and high-pressure washdown. A combination of IP66, IP67/68 and IP69K would provide the maximum ingress resistance.

Managing temperature extremes

Corrosion-resistant actuators tolerate temperatures of -40 to +185º F (-40 to +85º C). A wide temperature range means that different materials have been designed to work together at both normal and extreme temperatures. Not accounting for a wide temperature at the actuator design phase could result in excess corrosion, wear and ingress at the seals.

Because of their advanced materials, sealing, and temperature endurance, corrosion-resistant actuators need comparatively little maintenance. Some actuators can run up to 100 percent duty cycles and maintenance-free operation for up to 500,000 cycles (Figure 2).

Electrification of heavy duty applications

Machine designers have traditionally implemented pneumatic or hydraulic actuators for demanding applications, but heavy duty electric actuators now offer comparable performance to their counterparts along most dimensions. These actuators can handle high loads while remaining compact and without sacrificing any corrosion resistance. Specifying electric actuators with ball screws instead of lead screws adds strength, increases efficiency, and provides additional speed or force without increased current draw.

Industrial-grade actuators can achieve speeds of up to 100 mm/s. Speed requirements faster than that are more likely to be in applications such as high-speed, pick-and-place operations instead of opening and closing valves, and other adjustments, which is more characteristic of what might be required in a corrosive environment. These electric actuators bring functionality into corrosive environments that pneumatic and hydraulic cylinders can’t, including position feedback, energy efficiency and automation compatibility.

Position feedback

Knowing exactly where the load sits is critical for success in challenging environments. With onboard electronics, an electric actuator can calculate and share the exact position of the stroke at any point in time, so humans do not have to venture into hazardous areas. Fluid-based actuators, on the other hand, require complicated, high-maintenance infrastructure to get position feedback.

Energy efficiency

Pneumatic actuators may require desiccant to dry the air to prevent the freezing of condensation in colder climates, which is not an issue for electric actuators. Hydraulic actuators must run constantly to maintain the proper oil consistency, resulting in parasitic energy losses. Electric actuators are 10 times more energy efficient than pneumatic actuators and two to three times more efficient than hydraulic actuators.

Automation compatibility

As Industry 4.0 expands the scope of process automation, corrosive environments that have previously been poor candidates for automation are now coming into the fold. Taking full advantage of this emerging opportunity requires corrosion resistance and intelligence. In agricultural applications, for example, instead of farmers making multiple tractor trips into a fertilized field to adjust spreader settings, they are now likely to assign such a potentially corrosive assignment to AGVs or mobile robots. This solution requires technical integration that is only possible with smarter devices, and electric actuators are much better suited for the job.

Rising tides

Actuator designers are increasingly making corrosion-resistant products using advanced materials, improved sealing strategies and the ability to withstand extreme temperatures. This new generation of actuators requires minimal maintenance and can act as high-function replacements for pneumatic and hydraulic cylinders in corrosive environments if properly specified.Composed of stainless steel, sealed tightly and tolerant of wide temperature extremes, this new wave of corrosion-resistant, maintenance-free actuators can support loads and speeds most commonly found in corrosive environments (Figure 3).

Corrosion-resistant electric actuators in particular deliver position feedback more cost effectively, consume significantly less energy than pneumatic or hydraulic cylinders, and have the potential for greater integration with tomorrow’s advanced automation schemes.

About the Author

Travis Gilmer

Travis Gilmer is senior product manager of linear actuators at Thomson Industries, Inc. He manages the linear actuator business, supporting product line growth initiatives and product development efforts. He earned his Bachelor of Science in Industrial and Systems Engineering at Virginia Polytechnic Institute and State University and has worked at Thomson for 10 years.