Delta DSV steam traps released to North American market

Steam is one of the most expensive utilities for manufacturing plants in the US. Effective maintenance on a steam system is necessary to ensure high product quality and longevity of the steam reticulation system.

One specific area that requires ongoing maintenance are steam traps. Leaking steam traps waste energy, affect product quality, waste water, and adversely affect the environment through greenhouse gas emissions when more boiler fuel is used.

Blue Energy Technologies, official distributor for Delta venturi steam traps in the United States, is proud to announce the release of this innovative steam trap product line to the North American market. Blue Energy Technologies has worked hard to bring this product to market in the United States, where environmental issues and minimizing costs are important in the manufacturing industry.

Inefficient steam systems can dramatically reduce productivity and profit. For example, a failed steam trap with a 3/32" orifice operating at 100 psi can lose almost 30 pounds of steams hourly, leading to a loss of over $2,000 a year from each defective trap. According the U.S. Department of Energy in steam systems that have not been maintained for 3 to 5 years, between 15% - 30% of the installed steam traps may have failed, thus allowing live steam to escape into the condensate return system.

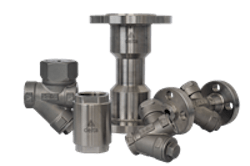

Delta DSV steam traps are innovative and utilize Venturi technology to collect condensate and block steam. Installing Delta traps will permanently stop inefficiencies and will operate properly even in varying load conditions. Unlike conventional steam traps, Delta steam traps have no moving parts which can wear out and fail. All Delta stem traps are built from stainless steel construction, and come with a 10-year mechanical and performance guarantee to ensure the trap will work properly, providing benefits to manufacturing plants for an extended period of time. Delta DSV traps have been found to reduce energy bills by up to 20%, reduce chemical treatment, and CO2 emissions dramatically.