Many factors influence a proper lighting system design. Among these are the costs of system installation, operation and maintenance. Additionally, the lighting quality for each task environment can have a significant effect on productivity, safety, efficiency and, ultimately, on the quality of the end product. Careful selection of lamp type, source and control can lead to significant energy savings while still providing the best possible visual environment.

Flexibility is a critical need in many plant environments. Changes in tasks or work zones; modifications of assembly, inspection or packaging areas; and plant expansion are among the concerns a lighting system should be able to accommodate. Key factors that influence a good lighting design also include the following:

- Occupancy type: A picking warehouse, a bindery and a small parts assembly line each has different layout and control needs.

- Tasks performed: This is a function of the visual acuity necessary for large machines with moving parts, fine detail performed manually or color rendering being critical.

- Plant environment: This addresses whether its unconditioned, the presence of harsh chemicals or explosive vapors, cold storage or processing.

Quality breeds quantity

Recent studies show a correlation between higher-quality lighting and better worker performance. In addition, when lighting quality improves for a particular task environment, the overall quantity (measured in foot-candles at the task surface) can be reduced without adversely affecting performance. Therefore, introducing lamps having a higher color rendering index (CRI), reducing glare, properly directing the illumination, and increasing a workers control over lighting levels can result in a system that consumes less wattage than an equivalent system without these considerations. Managing contrast and uniformity for the work area also has an effect.

If contrast is inadequate, a task can become much more difficult to perform.

Tuning your facility begins with an evaluation of each task type and environment that exists or might exist in the planned future. The Illuminating Engineering Society of North America (IESNA) recommends illumination levels based on the task, speed, accuracy, contrast and size. Using these guidelines, you can intuitively recognize that a warehouse requires significantly less illumination than an inspection station.

The best method for achieving flexible control is by continuous dimming, which permits lighting levels to be varied to specific levels. Fluorescent dimming ballasts typically can dim between 100% to 10% output, and T5HO linear lamps can dim as low as 1%. HID continuous dimming ballasts cant be dimmed much below 50% output.

Step-dimming permits lighting levels to be dimmed incrementally, typically at full, 50% and off. Step-dim ballasts are readily available for fluorescent and HID lamps, and control is by means of two switch legs rather than a dimmer.

Quality improves efficiency

Visually enhanced lighting (VEL) is an innovative way to offset total lighting energy demand. In 2004, the U.S. Department of Energy established a Spectrally Enhanced Lighting Program¹ that has funded several building retrofits to study the savings potential of using fluorescent lamps with a higher correlated color temperature (CCT). It showed that lamps with an 82 CRI and 5,000° CCT provide the same perceived brightness at a reduction of 20% to 46% of connected load when compared with standard lamps.

This is possible because light at higher CCT is cooler or bluer, and the human eye perceives this as brighter². In a retrofit setting, substandard illumination levels can be offset by a direct exchange of existing lamps for spectrally-enhanced lamps. Alternatively, energy consumption can be reduced by replacing existing ballasts with new electronic low-ballast-factor units while still maintaining perceived brightness. For a retrofit, expect a return of one to four years on the upgrade investment. In new construction, implementing a VEL design can provide additional efficiencies by reducing fixture quantities, power distribution requirements, air-conditioning load and peak demand.

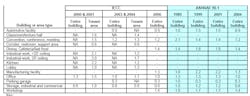

Many existing plant environments use high-pressure sodium (HPS) lamp sources for general illumination. HPS lamps are indeed more efficient than their HID and fluorescent counterparts. However, the quality of light is very poor, particularly where work is being performed for extended periods (warehouse shift, for example). The Visual Effective Illuminance (VEI) of fluorescent and pulse-start metal halide lamps is significantly higher than for HPS, which results in HPS being a net efficiency loser. As an example of potential savings, exchanging HPS lamps for T5HO fluorescents can reduce energy consumption while improving the visual environment, even though the lumen output is as much as 18% lower (Table 1).

Table 1 - Click to enlarge

Among the advantages of T5HO high-bay luminaires are improved lumen maintenance, longer lamp life, better color temperature and lighter luminaire weight (20 pounds vs. 50-plus pounds). For safety and reduced worker impact, the failure of a single lamp in the luminaire doesnt result in a total blackout. Also, if power is interrupted or if automatic shutoff controls are in use, the fluorescent lamps restrike instantly when energized. Battery ballasts can be provided for life safety without the need for separate dedicated emergency luminaires. As mentioned earlier, dimming and switching options for fluorescent high-bays are vastly greater than for HID or HPS sources. An option for a task area might include a six-lamp high bay with an occupancy sensor-driven four-lamp ballast and an emergency battery ballast for the two remaining lamps. This permits multi-level switching of 33%, 66% and 100%, with automatic shutoff of four lamps when the area is unoccupied, yet still ensure that the area is never in total darkness if power is interrupted.

Here comes the sun

Daylighting is making a comeback in the plant environment at an increasing rate. Properly implemented and designed daylighting can provide significant illumination during peak demand periods when its most valuable. A good design manages UV penetration, controls direct glare and permits artificial light to adjust to the available natural light.

Not only does this save energy, it improves worker performance. Because of the value of labor, even an increase in productivity of as little as 1% can quickly offset the cost of a daylighting installation. Ensure that daylight penetration doesnt result in excessive glare, reflection or heat gain.

Illuminating the future

A scalable or modular approach to the lighting system permits greater flexibility as your needs evolve. Modular wiring system permits luminaires to be added, relocated and serviced with a minimum of labor and downtime. Hook hangars with quick-disconnect modular cordsets permit a fixture to be installed or relocated quickly. A failed luminaire can be exchanged for a spare at bench level rather than in a lift basket. Simple splitters and extensions can be used with modular systems to permit changes to lighting density as plant needs change. Modular systems are available for industrial and wet location environments as well. There might be some tax benefits related to a modular wiring system because portable wiring can be depreciated at a faster rate than the building infrastructure.

Flexibility of control also is important if future needs require varying task illumination. The ideal control arrangement features digital addressing for each luminaire and control device. DALI open protocol is one option that permits as many as 64 devices to be managed discretely within each control group. All luminaires can be on the same load branch, because dimming and switching are performed via Class II low-voltage wiring. In a DALI arrangement, the control wiring can be daisy-chained between luminaires and controls, in whatever manner suits the installation. Each luminaire still can be switched or dimmed individually. Control can be by means of daylight and occupancy sensors, local controls, central scheduling or any combination of these. By combining addressable controls and modular wiring, an assembly line could be installed in a portion of the warehouse without any modifications to the infrastructure (Figure 2).

Recent trends and code changes

The 2006 NEC 410.73 requirement for a means to disconnect ballasts in double-ended fluorescent lamp luminaires takes effect on January 1, 2008. Exceptions to this requirement include manufacturing facilities that have a written luminaire maintenance procedure. The ballast disconnect is a safety feature that allows maintenance of a luminaire without having to shut off the entire branch circuit and leave the area in darkness. The disconnecting means also can be helpful for reducing labor when replacing ballasts.

Program-start electronic fluorescent ballasts are available in several ballast factors (measured as actual lamp output per rated lamp output), ranging from 0.77 to 1.1, allowing tuning of a luminaire by a range of 33% using the same lamp type. In addition, many of these ballasts are able to operate with 120- or 277-V input, thereby cutting down on the different ballast models that need to be stocked.

Linear fluorescent lamps are available with extended life and lumen maintenance ratings. Lamp life now extends to 36,000 hours for some series, with lumen maintenance of as much as 95% of the original output. Selecting these lamp types reduces total lighting density requirements and extends maintenance intervals.

Electronic HID ballasts are available for lamps as large as 400 watts in ambient temperature ratings of as much as 55° C. These ballasts use ceramic pulse-start lamps, which are more efficient and have better lumen maintenance than their predecessors.

Light-emitting diode (LED) sources are solid-state devices that are less susceptible to vibration, shock and low temperature. Their compact size also permits them to be fit into tighter spaces. LED sources dont emit UV radiation, which makes them well suited for UV-sensitive environments. Contemporary LEDs produce between 40 lumens/watt and 60 lumens/watt, which isnt as efficient as fluorescent or HID. However, theyre improving at a staggering rate, and are predicted to exceed 150 lumens/watt within the next five years. In comparison, pulse-start HID lamps operate between 100 lumens/watt and 105 lumens/watt.

EPACT tax credits, which go as high as $0.60 per sq. ft. of improvements, are still available to qualifying businesses[+]3[+]. The program has been extended to December 31, 2008. Credits are based on reduction of interior lighting power relative to the ASHRAE 90.1 (2000) energy code. A lighting power density that is 25% below code qualifies for a possible $0.30 per sq. ft. credit. If lighting power density is 40% below code, a $0.60 per sq. ft. credit is possible.

As energy codes mandate more automated controls and controllability, new products are being brought into the market to accommodate them.

Several vendors now offer automated powered circuit breaker systems that can replace the traditional lighting panelboard. By integrating overcurrent protection, relay control and intelligence into a single panel, installation becomes much simpler for the contractor. For more discrete control of small areas, relay sub-panels can be located closer to the loads being switched, while being networked together with main panel(s) for scheduling, override and other control needs.

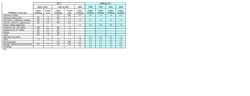

Both the 2004 ASHRAE 90.1 and 2006 International Energy Conservation Code (IECC) publications reduced the allowable lighting power density for buildings by an average of 26 percent (Table 2).

Table 2 - Click to enlarge

When evaluating your plant lighting or planning a new facility, dont discount the value of quality lighting. In most cases, a quality lighting system wont cost more than a traditional or typical design, once all factors are considered. Adjusting lighting levels to the task, introducing occupancy and schedule controls, and using high-efficiency ballasts and lamps can contribute to a better work environment while reducing energy consumption. Using spectrally enhanced lamps and daylighting can further improve efficiency and productivity. Dont use first cost as your metric for system selection. Instead, make your purchasing decisions based upon life-cycle cost. This will pay off for you, your employees and your product in the long run.

John McGonegle, P.E. is an associate and Chris Tilton, L.C. is lighting designer at KJWW Engineering in Rock Island, Ill. Contact them at [email protected] and [email protected] and (309) 793-3360.