Despite widespread popularity, Lean Manufacturing isn’t meeting leadership’s expectations. The Industry Week/MPI Census of Manufacturers released in November 2007 reports that almost 70% of U.S. plants are using Lean Manufacturing as an improvement approach, but only 2% of respondents have achieved their goals fully and only 24% report achieving significant results. This suggests that 74% of the participants aren’t making meaningful progress with Lean.

Might Lean be the wrong improvement tool? Or, instead, does the lack of success derive from the fact that most organizations aren’t stable enough to adequately implement Lean methodologies?

When implementing Lean, it’s important to gauge the organization’s ability to manage manufacturing assets in a proactive manner and manage manufacturing process reliability through visual controls, metrics and data. It takes a dedicated focus on reliability excellence to build a foundation of stability that accelerates the benefits of Lean.

Lean essentials

Lean Manufacturing is a set of concepts, tools and management prescriptions aimed at strengthening competitive advantages through process execution. Lean also is a culture focused on eliminating sources of waste and preserving optimum performance of equipment, systems and processes.

Lean Manufacturing, from a conceptual basis, originally was practiced within Toyota’s production system as early as the 1950s and has since migrated across geographic boundaries through industrial globalization. The core concepts of Lean that have led to the development of process and supply-chain management tools are Systems Thinking, Theory of Constraints, Mistake-Proofing and Just-in-Time.

Systems Thinking says every business is comprised of economic systems in which goods or services are traded or exchanged for monetary gain. Systems within your business either add to the worth of goods and services (also known as the value stream), or support the supply chain. Based on this premise, Lean Manufacturing methodologies are engineered to examine the enterprise as a whole, then break down the relevant components — systems within the enterprise — to further define those variables that constrain the manufacturing process and prevent performance from reaching full potential.

The role of reliability

In 2007, more than 7,200 professionals turned to the Center for Executive Education at the University of Tennessee (http://TheCenter.utk.edu) to learn Lean best practices. The top reasons why companies choose to implement Lean are pretty straightforward: maximize capital assets, improve customer satisfaction and reduce cost. But while choosing to implement Lean is straightforward, the actual implementation isn’t.

According to Dr. Alex Miller, dean of the Center for Executive Education, the main obstacles to implementing Lean include:

- Resistance to change from employees (most companies have more issues with management than the hourly employees)

- Lack of integration of Lean into the overall business plan

- Lack of stability in current processes, which can occur in the form of people, materials, process variation and machine reliability

Most Lean tools are designed to improve the organization’s ability to identify waste or sources of defects that might produce a constraint in your manufacturing process. However, Lean methodologies and tools aren’t designed to increase your organization’s ability to resolve chronic or complex problems effectively and efficiently. This is the focus of reliability excellence.

Reliability excellence and Lean manufacturing have two common objectives: increase flow and reduce waste. Lean manufacturing can’t reach its full potential in an unstable, reactive environment. Reliability excellence provides the asset stability, process effectiveness and cultural transformation required for a successful Lean implementation.

If a lack of stability can be a huge obstacle to implementation, why is it that the critical link between reliability and Lean gets relatively little attention? “Companies tend to get enamored with the results of a Toyota and fail to realize that Toyota has been working on these methodologies for approximately 60 years,” Miller explains. “Some organizations see a Lean implementation as a three-year to five-year project. They fail to realize that one of the absolutely critical building blocks is equipment reliability.”

Miller speaks from his experience working with a variety of manufacturing environments. “Inventory is an indicator of a weakness in the system,” he says. “Most companies use inventory to cover up equipment reliability issues. When they remove the inventory (i.e. when they adopt cellular manufacturing), equipment reliability issues become a high priority.”

Lean Manufacturing’s aggressive approach to operational improvement and cost reduction requires a significant level of organizational maturity to accurately identify opportunities for improvement that will yield the greatest returns. Simply said, a reactive organization is not mature enough to implement Lean successfully.

For example, in a reactive environment, the maintenance system, (known in reliability excellence terms as Work Control), might be incapable of keeping up with the volume of work requested through programs like Operator Care or autonomous maintenance. In this instance, Maintenance either will defer existing, programmed preventive maintenance or fail to respond adequately to defects identified by operators through the Lean implementation. Both decisions result in lower levels of manufacturing reliability.

Instead, if the maintenance organization is permitted to improve maintainability first, thus producing a more proactive maintenance management system, it will increase its ability to respond to operational requests driven by Lean practices.

Achieve reliability excellence

The technical definition of reliability is, “the probability that a system or component within a system will operate without failure under stated conditions within a given period of time.” Simply said, manufacturing reliability is a statement of dependability wherein the system consistently operates as desired. When defining reliability, your organization must understand the desired function of the system as well as the functionality of components within the system.

As we’ve learned, this also is the premise of Systems Thinking; however, reliability adds the requirement to establish practices that preserve system functionality and functional relationships between systems and components to preserve the integrity of the enterprise. Reliability excellence can therefore be defined as a business condition in which the structures, business processes and standards of practices exist to sustain manufacturing reliability, and are supported by a culture of discipline that focuses on consistently executing established practices.

In early 2008, The Center for Executive Education took the initiative to partner with Life Cycle Engineering (www.lce.com) to develop a new course, “Establishing Reliability Excellence for the Lean Implementation (Lean Reliability).” The course made its debut in October 2008. “We recognized that by not addressing reliability issues, many companies were failing in their attempts to implement Lean,” Miller says. “Subsequently, they abandon Lean and become even more vulnerable to offshore competition.”

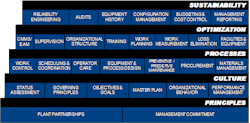

As illustrated by the Reliability Excellence Model (Figure 1), achieving manufacturing reliability requires a systematic approach that begins with alignment of organizational principles that foster management partnerships in reliability. Once in place, these partnerships serve as a foundation for transforming organizational culture from reactive to proactive. An organization that embraces Reliability Excellence believes that Operations owns the asset while Maintenance and Engineering work cooperatively to preserve the capacity of the asset to meet operating objectives.

The principles are expressed as written values that must be preserved throughout the transformation or improvement initiative. These values are then implemented via business processes as standards of practice within the daily routines of maintaining, operating and engineering manufacturing assets. Performance within each process can then be optimized by focusing on reinforcing systems that increase knowledge and skills, and improve the organization’s

Figure 1. Sustainable reliability is built piece by piece, beginning with partnership of

maintenance with production.

ability to manage the volume of work effectively. Finally, as the result of disciplined and dedicated reliability engineering practices, you’ve built a platform for sustainable and stable manufacturing performance. Once established, Lean Manufacturing methods might be applied to further refine the manufacturing process to enhance financial or environmental performance.

It’s important to note that Reliability Excellence also requires a significant focus on change management. Leadership must open an avenue for change by eliminating resistance within the organization, and then reinforce the change as it relates to each role or function of the manufacturing business. As organizations develop a culture of discipline through well-documented and established standards of practice, people become the most powerful tool for continuous improvement, and therefore must exhibit the right behaviors while executing established standards to achieve the full potential.

Ensuring that the correct foundation has been laid to build a Lean organization is one of the keys to companies being successful in their Lean journey. Once that’s in place, two other elements are essential to sustaining Lean: constancy of purpose by the leadership team, and correct performance metrics. Miller points out that as Lean methods are implemented, performance typically gets worse for a short period before it gets better. That’s when leaders need to “stay the course.” The leadership team also needs to make sure they focus on developing and tracking the correct metrics. The correct performance metrics drive desired behavior and it’s the right behaviors that create the right culture.

Critical steps

Before beginning your journey, follow these simple suggestions to confirm that your organization and its business processes and practices are mature enough to withstand the effects and resource demands of Lean.

Develop formal partnership agreements between Operations and Maintenance to set the expectation that reliability isn’t a maintenance thing, and transfer ownership of equipment care to operators. Define the partnership metrics that reinforce the agreements and identify when the business systems aren’t aligned with partnership expectations.

Assess the level of maintainability within each manufacturing area, or the ease with which maintenance is able to preserve equipment or manufacturing performance. Examine how the operating schedule might impede maintenance’s ability to maintain or restore assets to an acceptable condition. Determine who within the organization is responsible for the prescription of care and who is responsible for administering that prescription to sustain healthy assets.

Make a financial commitment to return areas of poor health to a maintainable state, both to improve maintainability and to prevent equipment failure from being the predominant and overshadowing cause of lost performance. In many cases, operator absenteeism accounts for nearly 20% of production downtime, yet in a reactive environment these losses are masked by poor equipment reliability.

Assess the risks associated with changing the organization from reactive to proactive. Determine the degree to which jobs, roles or functions within the business will change. Quantify the degree of risk based on perceptions of past management performance in either Lean or other operational improvement efforts.

Develop a change-management strategy to overcome the risk of change. Focus on communicating the need for change and linkages between Lean and “What’s in it for me?” Build personal desire for change and empower your organization with the knowledge about change and what to do after Lean is implemented.

Define and implement overall equipment effectiveness (OEE) as a leading indicator to identify and quantify the causes of lost performance within the manufacturing process.

Design an improvement plan that focuses on overcoming the reactive environment in the short term and, long term, implement systematic refinement techniques to further improve performance as the organization matures (Figure 2).

Figure 2. Just-in-time and build-to-order (Kanban) can approach

their full potential when reactive environments are eliminated and

maintenance techniques are refined over time to further improve

performance.

Align business leaders and gain their commitment to support the improvement plan with resources as defined by the activities. Agree to set aside initiatives that are less significant long-term and focus on the critical path as defined by the Maturity Continuum, applying resources as necessary to achieve the desired timeline.

Identify who will sponsor the improvement activities based on how the changes associated with proactive maintenance and Lean will affect the organization. Allow each sponsor to self-assess his or her ability to sponsor Lean based on competencies to actively participate in the improvement process, effectively communicate at all levels of the organization, and build a guiding coalition of peers to sustain management’s commitment long-term.

Dedicate full-time resources to manage the improvement process and steer the sponsorship committee through the cultural transformation. Establish a performance-management system that will monitor execution of the improvement and change-management plans while tracking organizational metrics relative to cost, capacity and environmental performance.

Implementing reliability excellence is a challenge. It’s a business process that requires cultural change, often to practices that have been in place for decades. But, the efforts are worth it because of the dramatic results achieved in moving from reactive to proactive, then experiencing the benefits of Lean.

Darrin Wikoff, CMRP, principal consultant, Life Cycle Engineering, specializes in organizational change management and business process reengineering. Contact him at [email protected] or (843) 810-5814.

U.S. Sugar cashes in on excellence |

|

U.S. Sugar Corp., Clewiston, Fla., is the largest sugarcane milling and refining operation in North America. The plant was built in 1932 and has undergone several capacity and modernization expansions, including the most recent breakthrough project that increased milling capacity to 38,000 tons per day and sugar refining to 13,594,000 Cwt. For the past two years, LCE has been working with U.S. Sugar to implement Reliability Excellence (Rx) in support of its strategic business goals and financial targets for product cost/unit weight. U.S. Sugar has realized significant improvements since partnering with LCE. They’re tracking OEE, identifying forms of losses and addressing the root causes. “In all the years I’ve worked in this business, I’ve never had better data to manage my department with,” says Darrel Collier, U.S. Sugar milling manager. The projected three-year return on this endeavor equates to more than $9 million in reduced operational expenses resulting from a 10% reduction in contract maintenance costs, a 30% reduction in labor cost and a 15% increase in capacity as measured through overall equipment effectiveness (OEE). OEE measures the three critical indicators of production system performance — availability, production rate and quality rate — to quantify the performance of each manufacturing module as well as the entire site. U.S. Sugar has the right metrics in place to understand where and when losses are occurring that affect its ability to operate effectively. |