Ultrasonic tanks take the hard labor and toxic danger out of parts cleaning

Parts cleaning in industrial machining and manufacturing has, traditionally, necessitated costly and time-consuming dedicated labor and toxic solvents. Additionally it has often required special chemical handling and disposal. Traditional cleaning has also not been thorough — cracks and crevices have been missed that couldn’t be cleaned with conventional equipment.

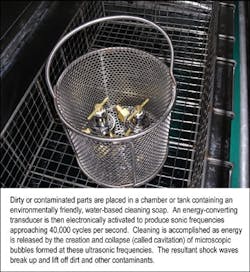

Many manufacturing concerns large and small are now discovering a great labor-, time- and toxic-solvent-saving device: the ultrasonic tank. Instead of specially outfitted personnel scrubbing and washing for hours on end, they can simply place parts to be cleaned in the tank, flip a switch and go attend to other matters.

“Our plant can’t afford to be slowed down or stopped,” says Bud Greener, manufacturing engineer at Eaton Aerospace of Jackson, Michigan. The company produces stainless steel, carbon steel and titanium tubing for conveying air, oil, water and Freon in a variety of aircraft and marine vehicles, and began saving 20 hours of labor per week as soon as they implemented ultrasonic tanks. “Prior to the ultrasonic systems, we cleaned tubes manually. Now, we put them into the cleaning systems, adjust the settings and walk away to do something else while the parts are being cleaned.”

The tanks utilized by Eaton and many others are manufactured by Omegasonics of Simi Valley, Calif. The tanks utilize specialized, environmentally friendly but effective cleaning solutions, including heat, water and ultrasonic sound waves for cleaning. Users have not only found the method to be more cost-effective in terms of labor and time, they’ve also found it to do a more effective job of cleaning due to cavitations within the liquid reaching areas unable to be cleaned by human hands or other devices.

An aerospace story

Eaton Aerospace has been in business since 1940, originally providing fluid power components for military aircraft. Today the company’s products are used in preeminent aircraft like the Airbus 380, the world’s largest passenger jet, the F-22 Raptor and F-35 JSF fighter jets, and also extend to marine applications.

Straight tubing arrives at the factory in diameters ranging from ¾ of an inch to 3 inches, and must be twisted into complex shapes for utilization. Tube sections are cut to length and bent with a lubricated tool called a mandrel, which is inserted into a tube to prevent kinking. Prior to the mandrel’s use, the tubes must often be cleaned of dust and particles. After bending, oils and tube-bending lubricants must be removed. “People are fussy about how their tubes look,” Greener says. It takes a clean, well-machined product to meet manufacturers’ tough quality standards.

For many years, Greener and his team cleaned tubing with mineral spirits and Stoddard solvent, a petroleum mixture that requires special storage, usage and disposal considerations. The company decided to pursue a more cost-effective and environmentally friendly solution to their needs.

Greener and his supervisor then discovered ultrasound products. Impressed by what they saw, they commissioned the company to retrofit two 300-gallon tanks. Omegasonics supplied generators and other components, as well as floor-model machines.

An encoder comes clean

Renco Encoders of Goleta, Calif., manufactures a line of optical encoders, used to precisely detect motion within mechanical devices. Renco has also saved time and labor with ultrasonic parts washing. Prior to installing their Omega Pro parts washing system, they used a hand-washing procedure to pre-clean components before placing them in a small-capacity, ultrasonic, table-top unit. In addition to the costly and time-consuming hand operation, the inefficient table-top unit could only hold a small quantity of parts. As a result, each batch of newly minted parts had to be divided and washed in several small batches with frequent solvent changes. Additionally the solvent was costly to use, and required an outside service for disposal.

With their ultrasonic system, Renco Encoders has now tripled their cleaning output, saving considerable time and money. They now also use a non-toxic, enzyme-based solution that lasts three months before it must be changed out.

Ultrasonic cleaning fits the mold

Plastic injection molding is a huge industry, constantly innovating to keep up with demand. Through heavy use, however, molds become contaminated with grease, hydraulic oil, rust, grime, carbon, aluminum shavings and material gassing, and many are still cleaned the old-fashioned way with labor-intensive hand scrubbing and solvents.

Gordon Schwartz, program manager at Kaysun Corp. in Manitowoc, Wis., not long ago received a challenging project: Find a better way to clean his company’s injection molds. After considerable testing, Schwartz determined that Kaysun could avoid hiring another technician for the price of a $16,000 ultrasonic parts washer. He chose an Omegasonics floor model based on its demo, filtration package and easy operator interface.

Wayne Hurkmans is the head of Kaysun’s mold maintenance department, and his mandate was to integrate the ultrasonic parts washer into the company’s operation. After he had done so, he confirmed that the time benefits have been outstanding. A mold with baked-on, carbonized hydraulic oil might take as long as three hours to clean by hand, but with ultrasonic technology, it takes only an hour. Even lightly to moderately contaminated molds might take 30 to 60 minutes with manual cleaning, whereas 10 minutes is all that is required with the ultrasonic washer.

"Molds look brand new," Hurkmans says. "Ultrasonic is quicker and cleans better, especially for intricate parts. Tool life is extended as well. Everything is just better with ultrasonic."

Ultrasonic parts washing has become the next evolutionary step in industrial manufacturing, greatly reducing time and labor, performing a better job of cleaning, and improving that all-important bottom line.

Bruce Boyers is a free-lance writer based in Glendale, Calif. For more information, see www.omegasonics.com.