Fabrisonic is now 3D printing sensors in solid metal

Sensors are used throughout industry to detect and respond to external stimuli. Unfortunately, conventional manufacturing processes often dictate that the sensors be placed far away from the stimuli. New 3D printing processes are allowing sensors to be embedded anywhere in a metal structure enabling:

- Higher protection –Sensors are surrounded by solid metal 3D printed into place.

- Higher performance – Sensor are located exactly where they need to be to optimize performance

- Design freedom – Metal 3D printing allows custom built transducers to be built in any shape

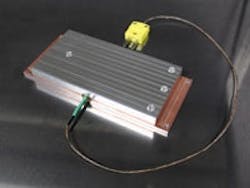

Ultrasonic Additive Manufacturing (UAM) is a new 3D metal printing technology that enables embedding of electronics and sensors into solid metal parts of any design. The process uses ultrasonic sound waves to merge layers of metal foil together in the solid-state, i.e., there is no melting of the metals. The process produces true metallurgical bonds with full density and works with a variety of metals including: aluminum, copper, stainless steel, titanium, and more.

Fabrisonic is now providing full service design, 3D printing, and calibration of custom transducers including strain, temperature, pressure, and acceleration.