Companies starting reliability improvement programs commonly hit an early roadblock: deficient data quality in their computerized maintenance management system (CMMS). The functional location structure and asset registry information in the system is a natural starting point for any vibration, lubrication, or other preventive maintenance (PM) or predictive maintenance (PdM) initiative, but in many plants a good percentage of this data is either absent, outdated, or simply erroneous.

If the foundations of reliability and maintenance programs are built on bad CMMS information, it will negatively impact the ability to meet reliability goals and unnecessarily waste troubleshooting time and money. Even facilities that try to follow a management of change (MOC) process may fail to keep their CMMS data up to date.

Often, the information is invalid because:

- It was brought in from an old system.

- It was never fully implemented.

- The people who set up the structure were inadequately qualified.

- The components no longer match the structure.

- New areas have not been added or kept up to date.

- MOC processes were inadequate or not followed.

- Area supervisors keep the information in spreadsheets.

But there is a simple yet underappreciated way to optimize the program: walk-down inspections. Visually verifying the accuracy and completeness of location and asset data by periodically walking around and auditing the plant—or at least critical equipment and areas—and correcting missing or invalid CMMS information is the best way to remedy discrepancies.

Consequences of bad data

When what is in the plant does not match what is in the CMMS, the consequences can be costly. Joyce Blom, a senior electrical reliability engineer at a major gas production facility, has seen examples firsthand.

“We had a case where a 15kV switch for a critical load was not in the CMMS system and was missed for its five-year maintenance. The switch eventually failed with an arcing short, causing a plant-wide power outage for a couple hours while the second of our dual feeders picked up the load,” says Blom. “It took over two months to repair the damage caused by the failed feeder switch. The associated costs were significant.”

Missing CMMS information also affects parts planning. “Motors without adequate information in our CMMS cannot be included in our critical spares plan as there are no motor suppliers willing to bid on a motor specification with missing key components,” explains Blom.

Bill Slygh, a reliability and maintenance consultant at Hendrix Precision Maintenance Services (Hendrix PM), has seen deficient information waste time for customers due to “garbage in, garbage out.” An example is running vibration on a fan that has a different bearing number than expected and the fault frequencies don’t quite line up. Or inspecting equipment that is said to be carbon steel but discovering it was replaced with stainless steel equipment.

“When walking down the equipment, you’re either going to validate what the CMMS says or validate that you’re looking at something different. These errors in the CMMS make troubleshooting slower and less efficient,” he explains, adding that it also creates spare parts identification and acquisition problems. If an equipment changeout doesn't get run through the MOC process, or there is no MOC process, the issues will add up and reduce productivity and extend downtime.

Scott Yenchik, a director of predictive technology and reliability services for B&D Industrial, recalls an incident in a prior role when a critical asset was down for an extended time because of incorrect data from not having a holistic process to review the CMMS, what changed in the field, and what was in the warehouse. “I don’t know what the total cost of the failure ended up being, but it was enough of a pain point for them to pay for a maintenance improvement project,” he says.

One of the main production pumps had inconsistencies in the bill of materials (BOM) in the CMMS, creating a “major expediting issue” to find repair parts. “There should have been a kit for the pump and that kit should have been a controllable item, but it wasn’t. This led to a whole CMMS review and installed-base evaluation walk-down, gathering nameplate data, looking at the assets and BOMs, and matching up all the technical information of what was in the CMMS and inventory,” he explains.

On the inventory control side, they looked for discrepancies between the CMMS’s BOM and the inventory warehouse, comparing what was in the bins and doing cycle counting. Then, they updated everything from the CMMS parts to the BOM to the criticality ranking of equipment and ABC analysis of MRO parts. “One of the biggest glaring holes was the lack of control of the warehouse, because the kits were basically getting robbed via ‘free shopping’ without capturing the documentation of requisitions,” Yenchik observes. “It was a tough lesson learned.”

Why walk-down inspections matter

The system only knows what gets put into it, reminds Yenchik. “It increases uptime and wrench time when you have the right parts when you need them. And there are ancillary benefits such as scheduling compliance and reduced overtime—it all adds up,” he adds.

Walk-down programs help to get your arms around particular groups of equipment, such as motors, electrical panels, or types of valves. “Once you have a sense of the scale, then you can work with your purchasing team and suppliers to develop spares and repair strategies for that particular group or type of equipment,” says Blom. “That is a huge advantage over tackling the component identification on a one-by-one basis.”

She notes that all walk-downs and audits generate money and time savings provided the learnings are documented in the CMMS system. For example, to purchase replacement parts these days, every supplier for parts asks for the model and serial number of the unit being replaced. Also, any contractor brought in to repair a system wants the model and serial number for the part they need to replace.

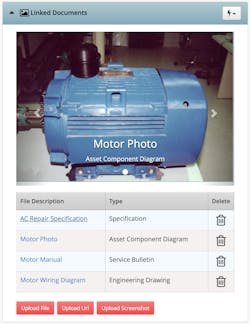

“Additional time-savings are that our maintenance planners prepare scopes of work to make clear the work requirements, beginning with indicating the model number of the parts to be worked on and context such as piping and instrumentation diagrams (P&IDs), location plans, equipment plan outlines, IOM manuals, and wiring diagrams,” Blom adds.

A further benefit of walk-down inspections is identifying process equipment inefficiencies. For instance, power is wasted if a process change means an 800 hp fan is intentionally run at a fraction of its capacity because less air is now required. Walk-downs can lead to installing right-sized equipment and putting expensive, overpowered equipment to better use elsewhere. Similarly, walk-downs can bring to light processes running with undocumented or unresolved workarounds so they can be addressed.

How to set up a walk-down inspection

Walk-down advocates have developed useful strategies for planning and optimizing the inspections. For instance, Yenchik recommends the following to anyone with CMMS data quality challenges:

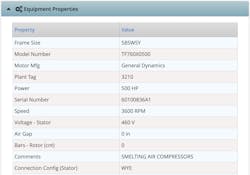

First and foremost, develop a process to review existing systems and walk-down field assets—or use somebody that has a process—even if it is just gathering general equipment information like the nameplate data to compare the BOM, OEM manuals, and verify what is in the CMMS. Tablets and software apps make field rounds and equipment walk-downs much easier.

- Conduct a standardized review twice a year, once a quarter, or whatever works for you, taking into account maintenance strategies and criticality.

- Start with your critical equipment first and then proceed to defined areas before approaching your balance of plant.

- Ensure that all components on your condition inspection program are present and correct in the CMMS.

- If you have people around the equipment doing PdMs, PMs, or operator care rounds, make it part of their normal process to take an extra minute or two to at least verify the installed equipment and nameplate data, or take a picture of it for later review.

Blom suggests leveraging whatever situation you find yourself in to develop the CMMS system, for example:

- If you find you have interns available, the interns can start learning the equipment by updating the CMMS.

- Make it a standard for maintenance personnel to take pictures of the equipment/device nameplate as part of their work and upload them to the CMMS.

- If outside contractors for are used for PMs, require detailed PM reports with photos of nameplates and equipment arrangements and upload them to the CMMS.

- Most suppliers have great databases of projects and parts that they have provided your facility in the past; ask these suppliers to share these databases with you to update your CMMS system.

According to Slygh, the problem is not having enough people to do a full walk-through. He advises:

- Do some type of self-assessment every three to five years, whether using internal or outside resources. Lots of outside companies do walk-downs—all the vibration and lubrication companies, for example—because they want to make sure they have the right information.

- Go into an area and check 10-20% of the equipment, and if you find issues, walk that whole area and update the CMMS.

- If the equipment nameplate or tag is too dirty to read all the information, try cleaning it off and get all the information possible. Then, go back into your files or to the manufacturer to fill in the gaps.

“For one reliability improvement project, one of the first things we did was assess the data,” says Slygh. “We chose a random list of 10% of the equipment in each area to walk down, with the expectation that if that 10% group was 95-97% correct, then we would accept the data. But if it wasn't, we would have to walk all their data down and make all the changes before we even started our process. We really need to have the asset list correct before we can start things like determining asset criticality or doing preventive maintenance optimization (PMO) projects.”

Fortunately, with the advent of the connected worker approach and the IIoT, the processes and tools have come such a long way that walk-downs are even more cost effective, observes Yenchik. “CMMS and reliability information management systems such as Tango are now joined by tablets, data visualization, and digitized asset/equipment information forms that can be filled out on the go and uploaded electronically to the CMMS. It’s like night and day,” he notes.

QR codes and scanner software are another advantageous development. They allow walk-down inspectors to quickly pull up the correct equipment record in the CMMS versus manually entering data from an equipment tag or card catalog. QR technology also streamlines and accelerates walk-downs due to improved location accuracy when every physical movement of equipment is tracked. Equipment QR codes can be scanned at install and removal, before and after repairs, and at entry and removal from stores.

Tasks to include in walk-down inspections

Completing any or all of the following tasks and updating the CMMS and any accessory reliability information management system will help to improve data integrity and reliability program success:

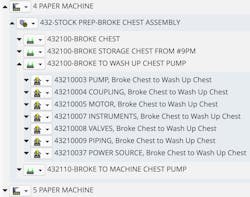

- Verify the asset location exists as identified in the CMMS.

- Add the asset location if not already in the CMMS.

- Verify all asset locations are in the CMMS.

- Check the availability of the location’s documentation (installation instructions, visual inspection checklist, manuals, procedures, service bulletins, warranties, original purchase orders).

- Perform a visual inspection.

- Take photos of the nameplate and component.

- Take baseline vibration levels and signatures.

- Install a plant asset ID tag on equipment that is repairable, if not already present.

- Verify and update as needed:

- the installed equipment nameplate information, including serial numbers

- the equipment ID as recorded in the CMMS

- the required lubrication type, amount, and interval

- the filter numbers (oil and air)

- the gauges and readouts

- coupling and belt information

- bearing and seal information

- the operation type (continuous, random, spared)

- whether constant or variable speed

- whether the component is rebuildable or disposable

- the P&ID number for each component

- whether the equipment is properly sized for its current process

- whether there are workarounds that need to be corrected.

- Check if the component is in the critical spares program.

- Verify the existence and location of critical spares.

- Check the status of the spares in plant stores.

- Check the status of required accessories in plant stores.

- Sketch the asset train layout.

Start now to realize reliability optimization

Maintenance and reliability programs succeed or fail based on the level of CMMS data accuracy. It is essential to establish and enforce procedures to ensure consistent data quality, including how to properly apply MOC to record all equipment and component changes, when and how to conduct walk-down inspections, and defining visual inspections. At minimum, assess and update your most critical asset information now using the tips provided above.

As Slygh pointedly reminds us: “There is an awful lot of opportunity out there for companies to clean up their databases because if they are not up to date, the data is not considered trustworthy, which will hamper your reliability improvement efforts.”

This story originally appeared in the November/December 2022 issue of Plant Services. Subscribe to Plant Services here.

About the Author

Forrest Pardue

Forrest Pardue is president and founder of 24/7 Systems Inc. After earning a BSEE at North Carolina State and then an MBA, Forrest has worked in the field of vibration analysis and PdM for more than 40 years. As one of the founding members of Computational Systems, Inc. (CSI), he was actively involved in the technical and market development of modern condition monitoring technologies. Following Emerson Electric’s acquisition of CSI in 1998, Forrest co-founded 24/7 Systems, a provider of reliability information management software and services.