By Bob Rice, Vice President of Engineering at Control Station, Inc.

It’s widely known that proportional-integral-derivative (PID) dominates the world of regulatory control. In fact, PID serves as the basis for the majority of PLC or DCS control systems used in the regulation of complex industrial production processes. For all of its expansive use in industry, though, the PID controller does have limitations. Occasionally single-loop applications of PID aren’t up to the task, requiring other and more advanced control solutions. Fortunately for PID, it is often a central part of that advanced solution.

Cascade control is an advanced control strategy that builds on the strengths of the common PID controller. Through the application of one or more additional controllers, cascade can improve a relatively slow process’s ability to counteract disturbances. In short, use of a secondary controller – or secondary PID control loop – can accelerate the process’s awareness of and response to disturbances. And as you might expect, a faster PID controller response delivers steadier overall process performance.

While improving a process’s capacity for disturbance rejection is a key to effective regulatory control and the core benefit of cascade control, this architecture, too, has its limitations. Consider the following aspects of cascade control before converting your facility’s single-loop controllers to Cascade:

- Cost considerations: The view that nothing in life is free certainly applies to process control. Indeed, the cost of cascade control is essentially double that of single-loop control. First there’s the hardware – a secondary controller is needed along with an associated sensor. Next are the configuration and maintenance costs – neither the controller nor the instrumentation installs and configures itself. A simple cost-benefit assessment can server as both judge and jury. If disturbances are crippling the process and hurting production, then cascade control may be well worth the additional cost. On the plus side, often the instrumentation already exists, and adding a new PID controller in a PLC or DCS is generally a simple task.

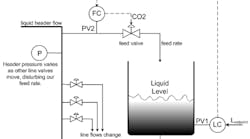

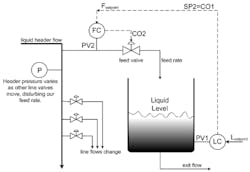

- Immediate influence: Cascade control requires use of a secondary control loop – a small albeit essential detail that shouldn’t be overlooked. What’s more, that same secondary loop must have direct control over the final control element (FCE). As a practical example, consider Figure 1. While it maintains influence over the process the primary level controller surrenders direct control of the valve to the secondary inlet flow controller. It’s the direct manipulation of the valve by the secondary flow loop that enables it to exert immediate influence over the process and to reject the negative effects of disturbances.

Figure 1: The ability to control liquid level in a tank can be vastly improved through use of a faster secondary flow control loop. The secondary PID loop exerts direct influence over the FCE and speeds up the process’ response to disturbances.

- Quickness counts: If the goal of cascade control is to get a jump on disturbances, then it stands to reason that the dynamics of the secondary control loop need to be faster than those of the primary control loop. In fact, they need to be at least 3-5 times faster. As with the tank example mentioned earlier, aligning a fast-acting flow loop with a slower-acting level loops – or some similar combination – fits this requirement to a T. Such a combination allows the quicker loop to serve as both an early detection and an early correction mechanism.

If the goal is to improve a process’ capacity for disturbance rejection, then cascade control could very well be the right solution. As a control strategy it capitalizes on the known strengths of the PID controller. Although it has limitations – or requirements – as listed above, cascade control has proved to be highly effective.

For more on cascade control, see these articles:

http://controlstation.com/overview-cascade-control/

http://controlstation.com/cascade-control-isnt-right-solution/

http://controlstation.com/pros-cons-cascade-control/