A Different point of View; Aligning your Maintenance Scorecard for Maximum Impact

March 20, 2008

The Maintenance Scorecard has now been implemented and adopted by companies from Europe, the USA, the Middle East and Asia. It is a succesful technique for driving real value from the physical asset base from the top to the bottom of any organization. This article addresses some of the frequently asked questions regarding implementation of The Maintenance Scorecard (MSC) as a tool for developing, implementing and monitoring strategy. In particular, it will focus on the need for a balanced point of view when creating measurement systems, and discusses various methods that the author has observed while implementing the MSC globally. Introduction

Maintainers are used to change, after all that has happened in the past 15 years who wouldn’t be? But few could have foreseen the incredible surge of attention that physical asset management has started to attract over the last 5 years in particular.

Events such as the swift adoption of PAS55 by a range of global infrastructure companies, the Energy Act of 2005 in the USA, and the recent resignation of Lord Brown of BP following the Alaska Pipeline and Houston refinery incidents, all point to one undeniable fact. Physical asset management is now a very serious business!

So much so that today we are seeing the convergence between physical asset management and financial asset management in many areas of human endeavor.

- Financial regulators in the United Kingdom are placing an increasing focus on the rigor that is put into their plans for capital spending, a multi-billion dollar area of activity for each 5 year period.

- Private equity firms the world over are acquiring infrastructure companies such as Thames water in the UK, BAA – the airport owner in the UK, Alta Link in Canada and practically everywhere else where there is an opportunity. Interestingly, these companies are not being stripped of their assets. Rather, they are being re-structured to maximize the income from those assets over the long term.

- Many European governments now use their infrastructure assets, and the contracts for their management, as a means of financing public spending in these areas. A modern and innovative spin on asset management.

- Many large estate owners now use comprehensive asset management contracts designed to shift risk of asset failure away from themselves and onto those providing the service. Another unique feature of modern asset management.

- How much are they producing?

- How much is it costing me?

- Am I getting good quality output on a consistent basis?

- Are we hurting anybody or damaging the environment in the process?

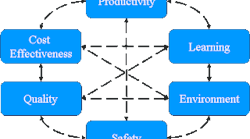

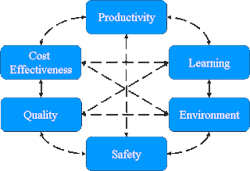

- How much are they producing? (Productivity (1))

- How much is it costing me? (Cost-Effectiveness (2))

- Am I getting good quality output on a consistent basis? (Quality (3))

- Are we hurting anybody or damaging the environment in the process? (Safety (4) and Environmental Integrity (5))

- Productivity – How well are our asset performing? How well is our workforce performing? Is there any hidden productivity that we can unlock in any place?

- Cost-Effectiveness – Are we getting the best value for each dollar spent on the maintenance effort? If not how can we lever even further value out of it? Note: This is not the same as low cost which is not a concept supported by the author. Low cost has a tendency to become high cost in the mid term, either directly or indirectly.

- Quality – Are we delivering the level of quality required in terms of production? Are we delivering the level of quality required in terms of asset maintenance performance?

- Safety and the Environment – Instead of the reactive measures of number of incidents, how can we proactively measure our exposure to risk of asset failure in these areas?

- Learning – How well are we managing the information (data + knowledge) we are learning from today’s activities, in order to fuel tomorrow’s improvements?

If you have previously considered a more thorough and sophisticated method for developing, implementing and monitoring strategy in your physical asset base then I hope that this article has provided you with something useful or at least something to ponder.

If you are still developing long lists of unconnected indicators, which bear only a passing resemblance to any objectives that your organization currently has, then I hope it has opened up additional areas where you may be able to continue to improve the performance of your physical asset base.