It’s an age-old air compressor question: Which is better, electric or diesel? The short answer: It depends. And much of it depends on the facility's needs. Is there access to electricity? Will the compressor be in a remote area? The answers to questions like these will determine which type of compressor is the best fit for your facility and applications. Let’s take a deeper dive into the pros and cons of electric and diesel compressors.

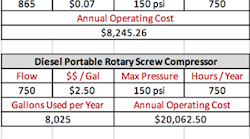

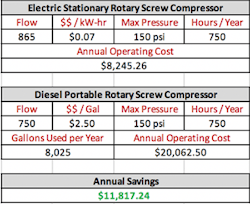

For some compressor operators, money talks. Manufacturing processes can be expensive, so reducing costs can be a very attractive factor. One of the key benefits of an electric compressor is its cost-effectiveness. Electric compressors do not require fuel, which makes them much cheaper to operate than diesel compressors. Electric compressors require only a power source to run and can be left practically unattended once they're plugged in and commissioned. The use of diesel compressors requires someone to monitor fuel-tank levels, because they can run for only about 12 hours before they need refueling. Furthermore, a diesel engine’s filters must be replaced every 250 hours – that’s every two weeks for a facility that runs 24 hours. Electric compressors can be left alone for up to 4,000 hours before maintenance is needed. That difference in maintenance levels is significant and can be a determining factor for compressor operators as both labor hours and budget dollars must be dedicated to machines that require additional maintenance.

In addition, with environmental regulations tightening, the fumes emitted by diesel compressors are a potential disadvantage. This is especially important to consider when there are limitations on how much diesel is permitted onsite at a given time. Also, while some diesel compressors have improved in recent years, the air quality coming out of an electric compressor generally is better. Because diesel compressors often don’t come with after-cooler, the air is hotter than with electric compressors, which means a lot more water goes downstream into the air systems.

The biggest relative advantage that diesel compressors offer is portability. Without the requirement of a power source, portability is the realm of diesel, allowing for optimal mobility. Road construction is the type of work where a diesel compressor is ideal.

When assessing your air compressor needs, ask yourself which priorities and advantages take precedence for your operation.