Improved intelligence: Transitioning to an enterprise intelligent asset management system

In this article:

But most recently, Industry 4.0, digital transformation, the Industrial Internet of Things (IIoT), smart factory, and the like, have changed forever how we view the management of our physical assets. The common thread through all of the technological advancement is improved intelligence, i.e., the ability to acquire and apply data, information, and knowledge from anywhere along the supply chain, from equipment manufacturers to customers. Therefore, a useful term denoting this latest phase is “Enterprise Intelligent Asset Management (EIAM),” meaning optimizing the management of all physical assets across an enterprise through the efficient and effective acquisition and application of relevant data, information, and knowledge along the supply chain.

The multiple dimensions of EIAM

The key enabler for the transition from “equipment maintenance” to EIAM is clearly technology. Your CMMS/EAM system, for example, plays a central role under EIAM. It allows businesses to collect and analyze asset-related data along the multiple dimensions that comprise EIAM, namely:

- across the departments, divisions, and business units of an entire organization, or even supply chain such as an organization providing contract asset management services;

- all functions and processes throughout an asset’s total lifecycle, from the design of assets, to their operation and maintenance, and ultimately, to their end of life or investment recovery, even if tapping the supply chain such as external contracted resources deployed;

- at all levels of an organization from the C-suite to the frontline, and along the supply chain where relevant;

- at any location geographically, from high-level region to the latitude and longitude of a given asset or work location, or along the supply chain;

- any other groupings within an organization (e.g., to manage all land or facilities enterprise-wide), even within the supply chain where relevant (e.g., facilities managed worldwide but owned by others).

To fully optimize along all of these dimensions is a daunting task indeed, especially for smaller organizations that are resource constrained. But regardless of the size of your organization, there are two problems. First of all, the CMMS/EAM system may be central and most relevant to a given business, but it is not the only technology. Secondly, and more importantly, it is not solely technology that will ensure success. It is something we humans tend to forget—technology is only an enabler. You have to do something intelligent with the data collected!

The EIAM model

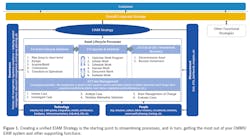

Figure 1 provides a model and context for successful implementation of EIAM. It all starts with an overall corporate strategy in light of customer needs. From there, functional strategies in support of the corporate strategy are formulated, such as an EIAM strategy, human resources strategy, information technology strategy, or operations strategy. The EIAM strategy provides an overview of the goals, objectives, performance measures, and targets, as well as action items needed to achieve them over the next three to five years. The EIAM strategy deals with all of the boxes shown in Figure 1 and described below, not just technology. Lack of attention to these other areas will almost certainly result in a less-than-optimal technology implementation and difficulty in achieving the expected business case.

Asset lifecycle processes. Improvements are most likely to stem from a change in processes rather than simply a change in software, hardware, or other technology. Sure, a faster piece of equipment may appear to increase output while processes stay the same; however, often changes are required in other areas such as how best to maintain the new equipment, how to ensure a steady supply of spare parts, and dealing with any design constraints. Certainly, a change in software such as a new or upgraded CMMS/EAM system will do nothing without an accompanying change in processes. Last year’s CMMS/EAM system industry trends article (https://plnt.sv/2011-CMMS) described each of the Asset Lifecycle Processes shown in Figure 1.

Measurement. Although performance measures and targets are part of an EIAM strategy (i.e., for the purpose of defining success quantitatively over the coming years), it is critical to breakdown those measures and targets to a sufficient level of detail that everyone in the organization will contribute to that success. Measures and targets must be meaningful to a given department, function, or level in the organization. For example, suppose part of the EIAM strategy is to reduce the number and severity of deficiencies in regulatory audits. At a more detailed level, key performance indicators (KPIs) might be percentage compliance of both plan to schedule and schedule to actual, for work on critical assets (target 100%), or percentage downtime on critical assets (e.g., target 0% through redundancy).

In theory, measures tracked by the CMMS/EAM system should define success for every process listed in Figure 1. For example, how do planners know they are working optimally? Measures like the ratio of preventive to corrective work, PM compliance, and so on are key to driving improvement to the “Schedule Work” process. Similarly, maintainers know they are doing a good job under the “Execute Work” process if they are meeting or exceeding quality and performance standards on the work orders. Implementing new technology such as a new CMMS/EAM system will require not just changes to processes, but changes in measurement that govern each process and drive the people doing it.

How to use CMMS data for reliability analysis

How to gain confidence in data quality

Getting the most out of reliability management data

Measurement should begin as a small set of key measures that trade off, like inventory level and number of stockouts (i.e., service level) when measuring the success of a spare parts inventory management process. As the organization progresses in its quest for a more comprehensive EIAM strategy, processes and the underlying technology improve such that collection and analysis of the data become more sophisticated. In turn, this enables improved measurement and the expected results. For example, in keeping with the spare parts inventory theme, suppose several changes are made to the processes and supporting technology as listed below. Note the suggested changes to measurement because of these changes:

- Introduce barcode or RFID scanning of items upon receipt, issuance, and return to inventory, as well as cycle counts on the CMMS/EAM system. Suggested measurement—track inventory accuracy using cycle counts and see significant improvements with the improved technology.

- Use the CMMS/EAM system to conduct ABC and XYZ classification using Pareto analysis. Suggested measurement—expand KPIs to include each classification such as inventory level and service level for “A” class items, “B” class items, etc., which should result in lower overall inventory levels and stockout percentages.

- For at least critical spares, and perhaps “A” class items, track actual lead times, reorder points, reorder quantities, or minimum levels on the CMMS/EAM system and compare to the values originally entered on the system. Suggested measurement: determine if values can be adjusted based on actual history, thus resulting in a lower inventory level and/or reduced stockouts.

As illustrated in the examples above, processes and measurement are critical in achieving an EIAM, not just technology.

People. It is often said that real change comes from a change in leadership. A strong leadership team with a clear EIAM vision can do wonders in moving from a reactive, fire-fighting culture to one that is more planned, efficient and effective, through utilization of technology to capitalize on the “I” in “EIAM.” Good leadership helps workers and their supervisors embrace change or move on within or outside the company. They attract and retain the best and brightest employees and build excitement around the transformation to EIAM strategy, including all of the training and hard work necessary to reap the benefits of changes to underlying processes, measurement, and technology.

Sometimes a change in organizational structure can get the ball rolling on the road to EIAM. For example, how is maintenance, operations, and engineering organized? Is there a common thread across these three functions and others tied to asset lifecycle, or is the organization in silos by department, division, function, geography, etc.? Are responsibilities clear such as asset owner and process owner, and relevant stakeholders are brought together for decisions regarding the management of assets (e.g., repair/replacement decisions, planned downtime, specs on new assets)? Is there equivalent to a chief asset officer (sometimes head of engineering) who takes the EIAM perspective in making executive decisions at the table with the chief operating officer, chief information and technology officers, chief financial officer, etc.? Who is the asset expert focused on the huge lifecycle cost of assets purchased in the name of Industry 4.0, cloud computing, smart factories, smart assets, artificial intelligence, etc.?

Companies have been slow to change in this area due to politics, ego, union-management posturing, and a host of other very human reasons. It is often easier to get approval to spend $1 million on a new piece of equipment or technology than to spend nothing on a simple organizational change regardless of benefit. This is why a solid leadership team can realize significant competitive advantage if successful in changing the culture and moving the organization along the EIAM continuum.

Governance. This is an area often overlooked by a large organization when it comes to the management of assets. Governance covers the policies, controls, and rules in place to manage assets. To achieve your EIAM strategy, governance will come into play in critical areas such as risk management, regulatory compliance, and contingency planning. Assets are getting more complex, more expensive, and more difficult to manage. Threats such as cybersecurity and system downtime loom large as offsets to the benefits of automation and cloud computing.

As well, environmental and social concerns such as energy consumption, hazardous waste, sustainability, and climate change affect the decisions we make and the EIAM processes/systems that we use regarding the management of assets. Now more than ever we are experiencing social and environmental pressure to achieve net zero, not just with the carbon footprint of assets, but everything. Depending on the industry, this may necessitate one approach for a major polluter of nitrogen, and something quite different for a company that has neglected to incorporate a significant recycling effort into the cost of managing assets. CMMS/EAM systems and integration with specialized software can help, but not in isolation. These big issues again underline the importance of senior leadership at the table focused on managing assets over their expected lifetime, as opposed to just financing, connecting, or operating them.

Proper controls are also key to governance as it relates to the processes, measurement, and technology like your CMMS/EAM system that supports these controls. This includes how we manage large projects for new capital, capital renewal, shutdowns, etc.; how we manage documents (e.g., version control), such as “as is” asset drawings, equipment manuals, and service contracts; and how we manage and control other industry-specific factors such as hazardous materials, external permits, and so on.

Technology. The driving force and major investment behind the transformation from EAM to EIAM is technology. Figure 2 shows Industry 4.0, smart factory, IIoT, digital transformation, and their many components, all of which have varying degrees of impact on our ability to manage assets across the enterprise, the supply chain, and along their lifecycle. However, reaping the rewards of this huge investment in technology is dependent on an organization’s ability to leverage the other elements of the EIAM model. Bear this in mind, and the hard work that goes along with it, as you read through the descriptions below of all the incredible advancements in technology currently available.

Technology supporting EIAM

Figure 2 provides a daunting list of technologies that are briefly defined below, including their relationship to EIAM.

Industry 4.0, smart factory, IIoT, digital transformation. Industry 4.0 has been used extensively in manufacturing (hence the terms “smart factory” or “smart manufacturing”); however, it has become synonymous with the digital transformation and connectiveness of assets, physical operations, and their supply chain for any industry via the internet (referred to as the Industrial Internet of Things or IIoT). These catch-all terms encompass many possible components, as shown by the blue boxes in Figure 2. Each company chooses technologies relevant to their journey in achieving their version of Industry 4.0.

Smart assets. Central to Industry 4.0 and EIAM are smart assets, especially for asset-intensive industries that have invested heavily over recent years in sophisticated physical assets to support the delivery of goods and services. Smart assets have built-in processing power and can be connected to the IIoT platform for monitoring and control of data. Just as refrigerators and cars have become smart assets for residential environments, so too have many industrial assets, from buildings to plant equipment and even smart city infrastructure.

Smart Sensors. One of the most significant enablers of EIAM and digital transformation is the falling cost and rising sophistication of smart sensors. A smart sensor has embedded microprocessors and wireless communication capable of transforming legacy assets into smart assets, for example, allowing remote monitoring and control of a process. Especially exciting are advancements in nanotechnology-based sensors or nanosensors, and the nanonetwork technology required for interconnectivity given the lower power and range of nanosensors. Industries such as food processing, health care, and defense are big users of nanosensors for detection and diagnostics.

Driverless vehicles, AGVs, robots, and drones. There is an enormous investment underway across many industries in smart mobile assets, such as driverless or autonomous vehicles, Automated Guided Vehicles (AGVs), robots or drones for countless applications. Examples of EIAM applications include driverless bridge inspections by drones, repair of equipment using robots for unsafe environments, and material handling of parts both within (e.g., via AGVs) and between companies (e.g., via autonomous vehicles).

CMMS/EAM system and other integrated systems. As shown in Figure 2, the heart of EIAM is the CMMS/EAM system integrated with a host of corporate applications such as enterprise resource planning, geographic information systems (GIS), document management, and project management systems. Depending on the industry, more localized applications can be integrated as well, such as specialized, data-intensive, condition-based maintenance systems for collecting and analyzing pipeline integrity, pavement condition, building conditions. Integration under EIAM can be expensive, complex, and time-consuming, so a careful analysis of cost/benefit should be done.

Cloud and edge computing. Cloud computing uses remote servers via the internet to manage and store data, as opposed to on-premise computing which utilizes your company servers. Sometimes edge computing is used to process time-sensitive data (e.g., driverless car data needed for quick reaction time), as processing power is decentralized to devices on the “edge” of your network instead of a central cloud. The applicability to EIAM is especially apparent when processing a steady flow of millions of data points, from potentially hundreds or thousands of sensors monitoring or controlling assets.

Big data and analytics. Successful EIAM will only come from sifting through the mountain of data available as described in this section, if and only if (1) source data is timely and accurate, and (2) there is a process for recognizing patterns, trends, correlations, and insights for optimal decision-making and action, both manual and automated (e.g., control systems). Big data is a term used when the enormity of data flowing is beyond the capacity of conventional systems. Many big data analytical tools have emerged to help companies process, analyze, store, distribute and safeguard the data.

Machine learning, AI, and XAI. Artificial Intelligence (AI) is used to simulate human thinking, such as diagnosing a problem based on extensive data, and even independently taking optimal corrective action. Machine learning is a subset of AI, i.e., training a machine how to learn. An example of EIAM using these technologies is helping maintainers predict which assets/components will fail using machine learning to analyze databases of engineering, operational, and maintenance records. Explainable AI (XAI) is relatively new but increasingly critical to EIAM, as regulators and other key stakeholders are demanding explanations as to why an AI engine came to a given conclusion. For example, if electrical power was cut to a grid at huge cost allegedly for “safety reasons” using AI, what were the underlying factors that drove the automated decision?

3D printing and additive manufacturing. These two terms mean the same thing, i.e., creating an object, layer by layer, from a given material such as plastic, using an asset controlled by computer-aided design or modeling software. The benefits to EIAM are enormous for some, such as creating just-in-time spare parts rather than relying on a time-consuming and onerous procurement and logistics process. Imagine the benefits to say, the defense industry on a remote battlefield when expensive assets require replacement parts.

Augmented/virtual reality. Augmented reality (AR) supplements the real world with a digital overlay using special glasses, goggles, or a smartphone camera, whereas virtual reality (VR) replaces the real world using an immersive special headset. In the world of EIAM, VR can be helpful for the safe but very realistic training of maintainers and operators, including simulating multiple virtual scenarios. Alternatively, AR can be used to provide step-by-step instructions on special glasses for trainees, or to maintainers on the job.

Digital twins and simulation. Simulation software models the real world to view possible scenarios, optimize a process, test the behavior of a given system or understand its characteristics. Digital twins uses simulation and potentially machine learning, but with real-time data collected from connected assets/sensors, to provide a visual representation of an asset or system over its lifetime. From an EIAM perspective, digital twins can therefore be used to predict failure of a process, asset, or component by analyzing maintenance and operational data collected over time. In turn, digital twins can improve the reliability and performance of assets.

Cybersecurity. As our dependence on technology grows, so is the threat of digital attacks and our need to protect against them. Cyberattacks can be simple annoyances like spam, or incredibly expensive and destructive like ransomware, competitive espionage, or even destroying critical data or smart assets. Thus, successful EIAM depends heavily on good governance practices, like risk management through cybersecurity.

Getting the most out of your growing investment in assets will take a lot more than increasing your spend on technology solutions as described above. The real work lies in sticking to an EIAM strategy governing changes to processes, as well as supporting measurement, technology, people, and governance.

This story originally appeared in the November 2021 issue of Plant Services. Subscribe to Plant Services here.