Which professional lubrication certification is right for you?

No one ever regretted an education. And no one ever regretted earning a degree, a diploma, or a certification.

Achieving a recognized level of performance satisfies several incentives: social recognition of your accomplishment, professional acknowledgement of content mastery, and a personal level of satisfaction. There are thousands of professional certifications for seemingly all disciplines. In the world of maintenance and reliability there are at least 10 for lubrication alone. With such choice, it can be confusing (and argumentative) as to which certification is best suited for a given position. This article organizes the offerings, and aligns them with job functions.

Two organizations stand out as global leaders in lubrication certifications: STLE and ICML. Established in 1944, the Society of Tribologists and Lubrication Engineers is the premier technical society serving more than 13,000 individuals and 250 companies and organizations that comprise the tribology and lubrication engineering business sector. STLE supports these distinguished men and women with a variety of professional education and certification programs.

The International Council for Machinery Lubrication is a vendor-neutral, not-for-profit organization founded to serve global industry as a world-class authority on machinery lubrication that advances optimization of asset reliability, utilization, and costs. ICML is an independently chartered organization consisting of paid professional staff members and volunteer committees.

Being in the business of lubrication for more than 25 years, STLE had the reputation of being an academic/sales-based organization with a balanced member representation of university professors, research and development scientists, and sales professionals looking to gain a professional advantage over the competition. That is not necessarily accurate. While membership is strong in the lubricant finished-product sector, there are many members who work for instrument manufacturers, raw material suppliers, or oil analysis labs, as well as many end users.

Michael D. Holloway is president of 5th Order Industry and has 30 years experience in Materials Research and Development, Machinery Lubrication and Reliability, and Oil Analysis. He holds a 12 professional certifications, 3 university degrees, and has published 5 books. Holloway currently provides certification preparation and competency development for reliability and lubrication professionals.

STLE offers four certifications, all of which require work experience, professional training, and a passing exam grade: the Certified Lubrication Specialist (CLS), the Oil Monitor Analyst (OMA) Level I and Level II, and the Certified Metalworking Fluids Specialist (CMFS). The CMFS will be explored in a future article that explores specialized certifications. STLE has recognized approximately 1,800 professionals globally.

ICML has a balanced membership of professionals who are certified representing all facets of lubrication research, production, and use. ICML currently recognizes more than 8,600 certified professionals globally and provides Machine Lubricant Analyst (MLA), Machine Lubrication Technician (MLT), Laboratory Lubricant Analyst (LLA), and the new Machinery Lubrication Engineer (MLE) certifications. The MLA and LLA certifications have been pioneered into ISO 18436-4 and 18436-5 Standards. ICML also heeded National Commission for Certifying Agencies (NCCA) guidelines in the development of its certification programs. Certification requires work experience, recognized training hours (except MLE, for which formal training is optional), as well as successful passing of an exam.

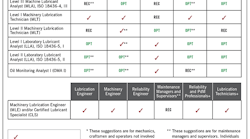

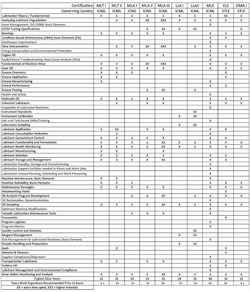

The following tables break down the areas that each certification embodies, the required work experience, and the required/suggested training class length.

Machinery Lubrication Technician - MLT

Level I - Targets in-plant technicians responsible for daily lubrication tasks, including oil changes, top-ups, greasing bearings, lubricant receiving and proper storage and care of lubricants and dispensing devices. 1+ years work experience, 16 hours of class hours.

Level II - Targets in-plant technicians or engineers responsible for managing the lube team, selecting lubricants, troubleshooting abnormal lubricant performance and supporting machine design activities. 2+ years work experience, 24 hours of class hours.

Machine Lubricant Analyst - MLA (ISO 18436-4)

Level I - Targets in-plant technicians responsible for the daily activities associated with lubrication tasks and basic lubricant analysis for machine condition monitoring, including, oil changes, top-ups, greasing bearings, lubricant receiving and proper storage and care of lubricants; dispensing devices and basic oil sampling, contamination control and problem detection. 1+ years work experience, 24 hours of class hours.

Level II - Targets in-plant technicians responsible for the daily activities associated with lubricant analysis for machine condition monitoring, including sampling, sample management, performance of simple on-site tests, managing test results and performing simple diagnostics. 2+ years work experience, 24 hours of class hours.

Level III - Targets in-plant technicians and engineers responsible for managing the lubricant analysis function. Tasks include team management, test slate selection, setting alarms and limits, sampling system design, instruments and software selection and advanced diagnostics. 3+ years work experience, 24 hours of class hours.

Laboratory Lubricant Analyst - LLA (ISO 18436-5)

Level I - Targets laboratory technicians performing daily activities, according to established ASTM procedures associated with testing of lubricant samples. Tasks include receiving and handling lubricant samples, performing tests, reporting results and inspecting data from individual test methods. 1+ years work experience, 24 hours of class hours.

Level II - Targets senior laboratory technicians, laboratory managers, and diagnosticians responsible for the daily activities associated with producing lubricant analysis data for machine condition monitoring. Tasks include performing test and analysis, diagnosing lubricant failure mechanism and modes instrument calibration and SPC based quality control. 2+ years work experience, 24 hours of class hours.

Machinery Lubrication Engineer - MLE

This is an engineering-level certification targeting reliability and asset management professionals with a strong emphasis in lubrication and lubricant analysis. The certification is ideal for those with daily activities associated with development, implementation and management of lubrication programs. It is intentionally structured for those with responsibility to guide and facilitate organizations in tactical step towards ISO 55001 certification. This is both an engineering and management level certification for those providing general engineering support to a user lubrication program including lubricant selection, lubrication and sampling hardware selection and implementation, overall lubrication program design, procedure development, optimizing lubricant PMs and inspection program design, lubricant analysis and troubleshooting, lubrication program metrics, training and skills remediation, and management/staff communications. 5+ years work experience, 40 hours of class hours.

Certified Lubrication Specialist – CLS

A Certified Lubrication Specialist is an individual who is designated as a “Lubrication Engineer” by his/her employer. However, it is not limited to this designation, as individuals from varied backgrounds, including sales and management, opt to become CLS certified to increase their credibility/standards. A Certified Lubrication Specialist’s core responsibilities including evaluating and selecting lubricants to use and their purchases, conducts lube surveys, trains lubricators and assembles work list, develops quality assurance and used lubricant analysis programs, troubleshoots and problem solves lubrication issues, maintains records of all application, as well as waste collection or disposal. 3+ years work experience, 32 hours of class hours.

Oil Monitoring Analyst – OMA

An Oil Monitoring Analyst is involved is a predictive maintenance professional who oversees the oil analysis program for a shop/plant. The OMA is recommended for mechanics, engineers, operators, tradesmen, chemical managers or on-site lab personnel whose core responsibilities oil sampling, reviews oil analysis reports and performs the correct tests, and maintains overall care of equipment and maintenance actions. 1+ years work experience, 24 hours of class hours.