Why you need an incident energy/arc flash analysis

In this ever-changing world we live in, the demand for high-efficiency electrical equipment is steadily increasing. With more electrical equipment to maintain and operate, workers are exposed to numerous hazards every day. One of those hazards is arc flash, or an arc blast, which can have devastating consequences. If there is an incident, the emotional and financial effects can be devastating. As illustrated in Figure 1, when you start to combine individual arc flash risks, you significantly increase the chances of an arc flash event.

In the United States, OSHA 1910.132 requires employers to access the workplace to determine whether hazards do or are likely to exist. OSHA references the National Electrical Code, NFPA 70E, and the IEEE standards for compliancy.

A common cause of noncompliancy is the misuse of the PPE tables in NFPA 70E. It’s often overlooked that NFPA 70E requires the available fault current and clearing time of protective devices to be known; in many plants, this is not the case. Also, NFPA 70E states that an incident energy analysis is to be performed when the following conditions are present:

- The worker’s task(s) are not listed in the tables

- Power systems have greater than the estimated maximum available fault current

- Power systems have longer than the maximum clearing times

- There are tasks with less than the minimum working distance.

When NFPA 70E tables are used instead of performing an incident energy analysis, some things to consider are:

- Notes in the tables that have specific requirements for the PPE are generally ignored

- The short-circuit current is assumed.

- The protective device clearing time is assumed.

Also, maintenance of the protective devices is not considered when the tables are used. This can affect the incident energy in the event that a sticky breaker or another protective device is not opening when it should, so the clearing time of the device would be inaccurate. It is also important to note that the tables and the arc flash calculations are not intended to work together. This is why NFPA 70E did away with the PPE values and identifies PPE with actual incident energy values for the analysis.

Insufficient training can also be a problem. Workers need to understand the correct use of PPE; they need to be able to recognize electrical hazards; and they also need to understand safe work practices. This training is required and specified by OSHA, NFPA 70E, and also the National Electrical Code. Additionally, these standards, as well as the National Electrical Safety Code (which is specifically enforced for utility companies), require that an arc flash assessment be performed. IEEE 1584 provides a procedure for performing the arc-flash hazard/incident energy calculations.

What is an incident energy analysis?

Now that we know that an arc flash hazard or incident energy analysis is required, what exactly does this look like? In a nutshell, mathematical methods are used to determine and, if possible, reduce the risk of personal injury as a result of exposure to incident energy from an arc flash. The purpose of the incident energy analysis is to identify the worker’s incident energy exposure, the arc flash boundary, the appropriate working distance, and the PPE’s required calorie rating.

The magnitude of the arc flash hazard is determined by the NFPA 70E equations or the IEEE 1584 standard, which was derived from actual test data. Arc flash hazard is expressed in incident energy with the units cal/cm2. Also, arc flash protective clothing is rated in arc thermal performance value (or ATPV), which is also expressed in cal/cm2. Essentially, you need to be certain that the cal/cm2 rating of the PPE you’re wearing is greater than the calculated incident energy (or cal/cm2) of the equipment you’re working on. With a proper arc flash study, this information should be presented on the arc flash label.

How can you be sure you are getting an accurate study? One of the top questions asked is whether an engineer is required to perform an arc-flash study. The correct answer to this question is “yes.” It is essential to have a qualified and properly trained individual perform the study – this should be a licensed professional electrical engineer (or PE). In most cases, the engineering board of the state or the governing body in which the study was performed requires that a PE certify the work.

It is important to understand that people’s lives depend on the accuracy of the information presented in these studies. If there is an incident, it is a guarantee that OSHA will look into whether the study was accurate and whether the individual who performed the study was qualified. It’s also a good practice to confirm that the study was performed with proven engineering software.

Incident energy analysis process

Each of the eight tasks listed in the incident energy analysis process is a crucial component of a complete analysis, and it is important that each be performed thoroughly and properly to create an accurate study that will generate the proper information needed to help protect workers.

1. Electrical one-line drawings. The process begins with the evaluation of the electrical one-line drawings, which should be kept up to date per NFPA 70E. For the study to be accurate, it is very helpful if existing electrical one-line drawings exist that show the full power distribution. The one-lines should identify the sources of power, voltage levels, and electrical equipment, such as transformers, generators, switchgear, motor control centers, panelboards, and protective devices.

2/3. Data gathering and system modeling. Where electrical one-line diagrams are not available, the data-gathering process must identify all of this information and essentially a one-line diagram is created with the gathered information. To properly perform the analysis, the process must be comprehensive. All equipment information should be gathered. This includes equipment ratings, arrangement of components on electrical one-line diagrams, the nameplate of every electrical device, ratings and trip settings of every protective device, and sizes and lengths of all conductors.

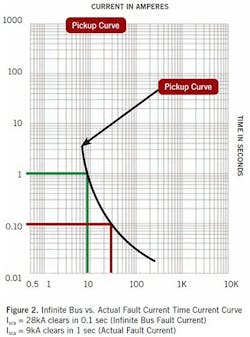

It is crucial to obtain the information on actual equipment. A lot of times, shortcuts are taken here; these can basically invalidate the study. The utility contribution, or available fault current, also is an essential piece of the puzzle for proper analysis. It can be challenging to get this information from a utility company. Often, an infinite bus calculation is used when the actual fault current cannot be obtained. However, with an infinite bus, the clearing time would be much faster than it would with the actual level of fault current; this results in a false calculation. (See the time-current curve in Figure 2.)

The gathered information is then typically input into engineering software in the form of a one-line diagram model with the correct information selected for each component. This provides the basis for comprehensive power system modeling in performing all types of analysis.

4. Short-circuit study. As part of the study, a short-circuit analysis is performed to determine whether the protective devices are properly rated to withstand a bolted-type short-circuit fault. To determine this, the maximum available fault current is calculated at each significant point in the system, and as an additional analysis, the bolted fault currents are converted into arcing currents. The results are determined based on the equipment’s existing rating.

5. Protective device coordination study. Another important aspect is the protective device coordination study. This allows the engineer to properly coordinate the protective devices so that you don’t have an upstream breaker tripping before a downstream breaker in the event of a fault. If this happens, it could shut down critical equipment or possibly even an entire facility, depending on the configuration. In most cases, a protective device coordination study also allows the incident energy levels (or the arc flash hazard) to be reduced at various locations with recommended changes of existing settings on the breakers or relays.

6. Incident energy / arc flash hazard analysis. The arc flash hazard (or incident energy) calculations also are performed as part of the study. As mentioned previously, the calculations are typically based on IEEE 1584; however, the calculations can be based on the equations depicted in NFPA 70E or NESC, depending on the type of facility and/or electrical equipment involved.

Also, per NFPA 70E Section 130.5, an incident energy analysis should be updated when major system modifications take place. This accounts for changes in the electrical system that could affect the analysis. The studies also must be reviewed every five years, at minimum. Changes to the available fault current or utility equipment could greatly affect the analysis, too. It is critically important to keep the studies up to date. If the information is not current, it is not reliable.

7/8. Written reports and labels. As part of the final deliverables, a written report is provided to inform the owner of the results and recommendations. Labels are applied to the electrical equipment showing the incident energy, PPE requirement, arc flash boundary and working distance for each piece of equipment. Electrical one-line drawings are typically provided with the deliverables as well, where the drawings can be customized to show specific incident energy levels, short-circuit current, etc. Also, as previously mentioned, because this is an engineering report and/or study, the documents typically must be certified by a licensed professional engineer.

Good safety practices

There are good safety practices that can be followed to minimize the risk of being injured during an arc flash event. One of these is to limit the presence of workers near potential arcing sources; this can be accomplished by increasing the distance between the worker and the source of the arc. Another good practice is to minimize the arcing energy; this can be accomplished through arc-flash mitigation methods, and it requires an arc flash study. Of coures, a vital protection measure is to always wear appropriate PPE; this, too, requires an arc flash study.

Limit presence of workers near potential arcing sources. Increasing the distance between the worker and the arcing source is very effective, as energy levels drop off exponentially as the working distance is increased. Several methods can be used to increase the distance between the worker and the arcing source:

- Remote racking – allows the racking of a circuit breaker outside of the arc flash boundary

- Chicken switch – allows the opening or closing of a circuit breaker outside of the arc flash boundary

- Time delay switch – allows a worker to move outside of the arc flash boundary before the circuit breaker is opened or closed

- Arc resistant switchgear – any potential arc is shunted away from the worker and extinguished

Arc flash mitigation methods. Mitigating high incident energy levels can be achieved through several methods, some of which are very cost-effective. Arc flash mitigation will, of course, require an arc flash study, and it will involve engineering methods to determine proper protective device coordination to go along with reducing incident energy levels. These methods include:

Ryan K. Downey, PE, is the engineering manager for AVO Training Institute. His experience includes electrical, controls, and instrumentation design of substations and power distribution systems; power system analysis, including short-circuit analysis, protective device coordination, arc flash hazard/incident energy assessments, and harmonics analysis; grounding and lightning protection systems; and electrical energy audits. He’s a member of the IEEE 1584 Working Group – Guide for Performing Arc-Flash Hazard Calculations and IEEE 1814 Working Group – Recommended Practice for Electrical System Design Techniques to Improve Electrical Safety.

- Protective relaying schemes, which are fast-acting control mechanisms. Common relay schemes include: (1) bus or transformer differential protection, where a relay compares the primary and secondary currents at a transformer (differential protection can be used to protect a specified zone); and (2) arc flash detection relays, which typically use fiber optics and current detection to sense “true” arcing events. The use of light and current can reduce or eliminate false tripping. Some systems also use sound, or ultrasonic devices, as a third component.

- Current limiting fuses are fast-acting fuses in which the clearing time and peak current are greatly reduced. They may be limited in use, however, given that they typically only work for high fault current levels.

- Adjustable circuit breakers – Long-time pickup, short-time pickup, instantaneous (LSI) breakers allow the shaping of tripping curves and typically offer better performance across wide range of fault current levels. A protective device coordination study is required to properly coordinate the various upstream and downstream breakers. Zone-selective interlocking is also an option; this allows trip devices to communicate with each other so a fault is cleared by the nearest circuit breaker, with no intentional time delay.

- Maintenance mode circuit breakers – Instantaneous settings are adjusted during routine maintenance to reduce the incident energy levels.

Wear proper PPE. Of course, the thing we all need to make sure we always do: Wear proper PPE! Too little protection can result in serious injury or death. Too much protection can cause limited worker mobility or visibility. You need to know the exact type of PPE required for the task – this is what an arc flash study will tell you.

Conclusion

So what do you do after the analysis is completed? You need a plan to keep it maintained! You need to be certain that the study is reviewed every five years or updated with any system modifications to keep it accurate. Analyzing the electrical system every five years will identify changes affecting the results of the previous analysis. Analyzing the maintenance plan will help integrate any changes into the system.

You now have three choices:

- You can do nothing and increase the risk of a fatality or injury occurring. This also increases the risk of fines, litigation, and higher insurance premiums, and that OSHA (or another governing agency) will knock on your door.

- You do something but do not require or do not know the correct PPE that workers should wear. Workers could have inadequate or excessive PPE, which could result in an accident, again increasing the risk of fines, litigation, higher insurance premiums, and OSHA (or another governing agency) knocking on your door.

- Or, you can have an analysis performed by a licensed professional engineer. You will be in compliancy with the codes and standards, and you’ll help protect those who work on electrical equipment.