The number and pace of companies benefitting from the industrial internet of things (IIoT) is increasing. More and more organizations are piecing together its components – the cloud, big data, smart devices, and software – to establish a network of connected assets, automate business processes, and generate advanced decision-support analytics.

Each success serves to further justify an extension of the strategy, creating a sustainable competitive advantage for IIoT leaders. Targeted or trial implementation “wins” validate the value of the IIoT, providing the impetus to roll out the state-of-the-art information technology (IT) and operations technology (OT) to more equipment and locations.

The greatest progress in IT/OT convergence is in the area of asset management, says Craig Resnick, vice president of consulting at ARC Advisory Group. “Having the opportunity to plan and schedule a shutdown and avoid unscheduled downtime is where you get the immediate payback,” he explains.

A challenge is that plants tend to operate multiple generations of equipment and systems – some many decades old. For example, rotating assets such as pumps or gearboxes typically last a long time, but can cause unscheduled downtime when they fail. “Putting low-cost sensing devices onto these assets to look at things like vibration or bearing temperature helps to come up with the predictive analytics to optimize when to repair or replace the assets,” says Resnick.

Stanford University accelerates asset management ROI

The Central Energy Facility (CEF) at Stanford University successfully upgraded its corrective and preventive maintenance model to an IIoT-enabled predictive maintenance (PdM) approach. Dan Arellano, associate director of energy operations maintenance, described the process to an audience at ARC Industry Forum Orlando 2018.

He explained that CEF, constructed in 2015, powers more than 200 buildings ranging from hospitals and research labs to dining and residence facilities. Unplanned downtime could be devastating to those needing power. For instance, cooling capacity curtailment could cause hospital operations to be cancelled.

Initially, repair costs were high and maintenance decisions relied heavily on personal observations. Little was known about actual machine conditions, and process issues weren’t known until latest-stage machine failure.

The university quickly decided to invest in improvements, including:

- Wireless vibration sensors to collect and send machine condition data over WiFi

- An enterprise-grade cloud infrastructure

- Automated analytics with machine learning capabilities to analyze asset data

- Web and mobile apps for real-time asset monitoring and to receive actionable alerts

The first assets to be instrumented with wireless sensors were critical pumps and cooling tower fans. It wasn’t long before defects were detected, allowing maintenance to be scheduled in time to prevent failure. Examples included deadheading of a heat exchange pump, slipped coupling on a hot water return pump, and worn gear teeth on a cooling tower gearbox.

The rapid ROI that resulted prompted IIoT expansion plans. CEF now seeks to instrument the entire fleet of equipment; evaluate multiparametric solutions to automate monitoring of assets such as variable frequency drives, steam traps, and electric panels; and integrate the wireless PdM condition data into enterprise asset management (EAM) workflow processes.

Offshore driller digitalizes analytics and asset management

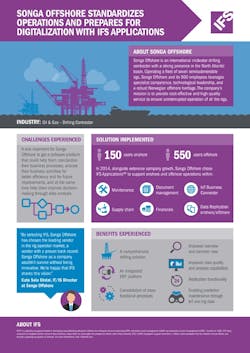

Replacing calendar-based maintenance with a digitalization and automation strategy is driving greater asset reliability and more cost-effective operation for international midwater drilling contractor Songa Offshore.

IIoT sensors attached to pipes, diesel and electrical engines, and other critical equipment are driving PdM and condition-based maintenance (CBM) of the company’s four semi-submersible rigs. “We want our intelligent equipment to tell us when it needs to be repaired,” explains Cato Sola Dirdal, IT director at Songa Offshore.

Asset readings and sensor signals from the integrated digital assets are automatically collected and transmitted to the driller’s EAM software, which generates work orders as needed. It replaced a previously manual process where roughly 600 asset readings were collected every hour, from every rig, and entered in the maintenance system.

Around-the-clock condition monitoring of connected assets is paving the way for improved reporting, analytics, and forecasting. Songa also plans to use CBM for continuous classing of its rigs while in operation, rather than taking them out of service every five years to conduct a special survey.

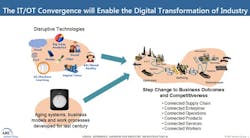

Figure 1. The IT/OT convergence will enable the digital transformation of industry. (Source: ARC Advisory Group)

Tobacco company applies IIoT in legacy environments

A well-established tobacco company is using the IIoT in its corporate-wide pursuit of operational excellence. It set out to reduce costs and increase efficiencies by replacing homegrown manufacturing systems developed over 20 years with advanced, integrated software and technologies – standardized corporate wide. It would be a collaborative effort involving IT, OT/Engineering, Manufacturing, and Maintenance.

The journey began by establishing a common manufacturing execution system (MES) framework. The rollout that followed over several years included the new MES software, automated machines, primary and secondary controls, ERP standardization, an historian, analytics, and PdM solutions.

Figure 2. Songa Offshore standardizes operations and prepares for digitalization with IFS applications. (Source: IFS)

Today, integrated systems are employed in multiple business units and locations, including batch and continuous process manufacturing, discrete manufacturing, and warehouse environments. They provide an IIoT platform that is both scalable and extensible to accommodate changing business requirements and new innovations.

Immediate and recurring cost savings and business benefits are being realized. Order and materials management, operational performance, traceability, and quality metrics have been positively impacted, while the costs and risks of obsolete legacy systems were eliminated. In addition, enterprise-wide standardization and best practices are enabling greater consistency of delivery, and continuous improvements will keep the company on track for its digitally connected enterprise vision.

It’s never too late to start

For companies still early on the IIoT path, start auditing your older assets and developing a strategy for how they can be better monitored and managed, encourages ARC Advisory Group’s Resnick. “Work with your existing sales channel, systems integrator, and automation suppliers, and ask them to come in and audit at minimum your rotating assets,” he suggests.

Nobody’s going to replace an existing pump with a smart pump with built-in sensors unless the existing pump is no longer doing what it was designed to do, Resnick observes. For older assets still working as designed, install low-cost sensors as additive to the existing assets, set up a program in the cloud, and deploy analytics software to help understand how to better maintain these assets.