Airborne and structure-borne ultrasound has been around for more than 50 years. In the technology’s early days, the main application was compressed air leak detection. Even today, that’s still the most widely used application for airborne ultrasound.

Over the years, through advancements in ultrasound instrumentation and software, more maintenance and reliability personnel have begun to use ultrasound technology for more than just compressed air leak detection. Three applications in particular have seen a large increase in use: condition monitoring of bearings and rotating equipment, condition-based lubrication using ultrasound, and electrical inspection of energized electrical equipment.

Ultrasonic equipment detects airborne and structure-borne ultrasounds normally inaudible to the human ear and electronically “transposes” them into audible signals that a technician can hear through headphones and view on a display panel as a dB level. On some instruments, incoming sound can also be viewed on a spectral analysis screen that shows either the FFT or the time wave form. With this information, a trained technician can interpret the bearing condition to determine what, if any, corrective action is needed, and the current data can be compared on the spot with the baseline data.

Ultrasound technology has many advantages:

- It can be used in virtually any environment.

- Learning to use ultrasound technology is relatively easy.

- The technology is relatively inexpensive.

- Modern ultrasonic equipment makes it easy to track trends and store historical data.

- Ultrasonic technology has proved itself to be extremely reliable as a predictive maintenance tool, helping organizations save thousands of dollars and hours of productivity.

- There are remote monitoring options for both mechanical and electrical applications.

Airborne and structure-borne ultrasound instruments are an extension of the user’s sense of hearing. Similar to how vibration feels what you can’t feel and infrared cameras see what you can’t see, ultrasound hears what you can’t hear. There are sounds in a typical manufacturing environment (machines running, etc.) that prevent us from hearing other sounds, such as compressed air leaks or electrical discharges such as corona, tracking, or arcing. Ultrasound instruments listen for sounds that are not present in our normal audible range.

Typically, the sounds outside normal human hearing are high-frequency sounds. The high-frequency sounds are detected by the instrument and translated through a process called heterodyning into an audible sound that the inspector hears in the headset. The unit of measurement for sound is a dB level, which is indicated on the display of the ultrasound instrument.

Why remote monitoring with ultrasound?

Remote monitoring with vibration analysis and temperature has been available for many years. For ultrasound, remote monitoring is a fairly new addition to the technology’s repertoire of capabilities. When you’re considering adding ultrasound to your condition monitoring program, your decision will depend ultimately on which assets you would like to monitor. Once you have determined the assets that you would like to monitor, you need to identify the failure modes related to those assets. Understanding how those assets will fail will help you determine which condition monitoring tool can be applied to find those failure modes.

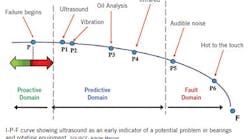

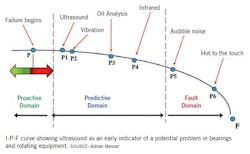

Ultrasound is a proven technology that can detect certain mechanical and electrical faults much sooner than other technologies can. By sensing subtle changes in ultrasonic amplitude, ultrasound is adept at finding early-stage premature bearing faults, as demonstrated by the I-P-F curve.

Ultrasound plays a critical role in helping extend the life of bearings in the I-P interval by condition lubrication of bearings. Studies have shown that the majority of premature bearing failures can be attributed to lubrication errors. Whether it’s over- or underlubrication, using the wrong grease for the wrong application, or lubricant contamination, it all comes back to improper grease application. Ultrasound can prevent over- and underlubrication, thus potentially eliminating a large number of bearing failures.

When a bearing lacks lubrication, there’s an increase in friction. The higher friction also increases the amount of ultrasonic noise the bearing produces; this is indicated by a rise in the decibel (dB) level. When greasing a bearing that needs lubrication, one should see a gradual decrease in the dB level. Once the dB level has fallen back to a normal or baseline level, greasing can cease. If the bearing already has sufficient grease, then the dB level will slowly begin to rise as more grease is applied. That’s because overlubrication also increases friction in the bearing housing, thus producing a higher dB level. The inspector would notice the rise in dBs as grease is applied and would stop greasing.

In the P-F interval, once a failure has begun, ultrasound is excellent at finding it. These are bearing failures that can be detected even before changes in vibration are. If you’re monitoring critical assets, ultrasound and vibration should be used together in an effort to potentially detect multiple failure modes that may be missed when using one technology alone.

Remote monitoring - mechanical inspection

Remote monitoring of bearings and other rotating equipment with ultrasound can be done one of two ways.

The first is by using wired remote access sensors (RAS). The sensors are mounted to the assets when it is safe to do so, and the cables are brought out to a safe area (outside of guarding) where they can be connected directly to a portable handheld ultrasound instrument. The cable lengths for the ultrasound remote access sensors can be made to up to 100 ft (30.48 m).

The ultrasound remote access sensors can also be connected to a junction box or a switch box. As many as 12 ultrasound remote access sensors can be connected to one switch box. Similar to the way vibration-analysis switch boxes work, the ultrasound sensors are connected to the switch box along with the handheld ultrasound instrument. During analysis, the inspector turns the dial to the next point to collect a reading.

Remote monitoring with ultrasound can also be done continuously via a sensor that offers an audio output for easy connection to plant process monitoring systems. This audio output will allow for sound recording for further diagnostics or for comparing baseline sound files with alarm level sound files. With adjustable alarm levels and dB threshold settings, this type of sensor can be used to track alarm conditions and trend potential problems.

Remote monitoring - electrical inspection

Ultrasound can be used to inspect almost any energized electrical equipment. This may include metal-clad switchgear, transformers, substations, relays, and motor control center, along with many others. Ultrasound can be used to measure equipment voltages from the low end (110 volts) to well over 12,000 volts (12kV).

Traditionally, inspection of energized electrical equipment has been performed using noncontact infrared cameras. However, increasingly, ultrasound is being added to these inspections. One of the main reasons has been safety: An ultrasound inspection of electrical equipment can be done without the need to open the energized cabinet or enclosure. The handheld ultrasound instrument is used to scan openings on the cabinet. The high-frequency sound produced by corona, tracking, and arcing from inside the enclosure will exit through the openings. The inspector will hear the sound via the headset and know an anomaly is present. The sound can then be recorded to determine whether the condition is corona, tracking, arcing, or some type of mechanical looseness.

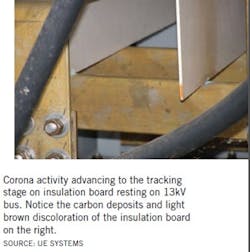

Corona refers to the ionization of air surrounding an electrical connection higher than 1,000 volts. Corona by nature does not produce significant heat that would be detected by an infrared camera. However, it does produce high-frequency sound that can be detected by the ultrasound instrument. If corona discharge continues to occur, it can lead to a more severe problem such as tracking or arcing. By-products of the ionization process are ozone, electromagnetic emissions, ultraviolet light, and nitric acid. The nitric acid is a corrosive and can deteriorate insulators and connectors and lead to tracking and arcing.

When the sound file of corona is recorded, signature characteristics visible in the FFT and time wave form (TWF) will help diagnose the condition. For corona, the discharge points occur only at the highest-voltage point on the sine wave. This means that the amplitude peaks in the TWF are somewhat equally spaced as the discharges are only at the positive peak of the sine wave. The result will be well-defined 60Hz or 50Hz harmonics.

Tracking (low current pathway to ground across an insulator) and arcing (electrical discharge to ground across an insulator) also have characteristics to look for. With tracking, the discharge does not have to take place at the peak of the wave form. Instead, it can happen anywhere on the positive portion of the cycle. The spacing of the peaks in the TWF would be similar but not uniform. As tracking becomes more severe, there would be more discharge events and therefore more nonuniformly spaced narrow peaks.

Arcing has the most nonuniform “look” in the FFT and TWF. Only the bursts of the discharge can be heard, and these will be seen as wide peaks in the TWF view.

A remote mounted sensor that offers a heterodyned audio output to allow for sound recording can be a valuable tool for electrical inspection. Analyzing recorded ultrasounds of electrical anomalies is the only way to diagnose with ultrasound the condition heard. For optimum flexibility, consider an ultrasound sensor that can be mounted inside of an electrical cabinet such as a transformer or switchgear and wired into the facility’s process monitoring systems or a PLC.

Adrian Messer, CMRP, is manager of U.S. operations at UE Systems. Contact him at [email protected].

Conclusion

Remote monitoring with ultrasound is a viable option for maintenance and reliability programs that are already monitoring assets traditionally with handheld devices and for programs where ultrasound is not currently in use.

Because it is complementary to vibration analysis for mechanical inspection and infrared thermography for electrical inspection, ultrasound will only enhance existing condition monitoring efforts. In areas that are remote, inaccessible, or dangerous, remote monitoring with ultrasound may be your only option. Additionally, a multitechnology approach to condition monitoring increases your chances of finding multiple failure modes and detecting them early enough to make necessary repairs before problems become catastrophic.