Prescriptive analytics and asset management: Putting analytics into action

Prescriptive analytics bring a higher level of efficiency to asset management decision making. By synthesizing condition-based and predictive maintenance decision processes with operational data modeling and mathematical algorithms, doing what needs to be done – and when – is simplified. Prescriptive maintenance puts the analytics into action.

Prescriptive analytics and maintenance are cognitive computing tools that incorporate modern technologies such as pattern recognition, machine learning, and artificial intelligence. They can be used to monitor and trend equipment performance in the field, predict performance expectations going forward, and compel the necessary actions to achieve the desired operations and maintenance outcomes.

Any individual or entity responsible for asset management can benefit from a prescriptive approach, whether it’s an original equipment manufacturer (OEM), an end user maintenance organization, or a third-party service provider.

Well-developed prescriptive analytics solutions will draw from business intelligence (BI), operational intelligence (OI), enterprise asset management (EAM), enterprise resource planning (ERP), material requirements planning (MRP), and other business information systems and prognostic tools. Countless data points can be factored into the algorithms, such as asset criticality, work priority, fault data, ambient temperatures, and the average lifespan of a given part.

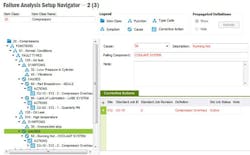

Using this data, the solution will model “what if” scenarios of possible options and outcomes down to the work execution level. Each option is systematically evaluated in order to identify the optimal course of action, and that recommendation is then pushed to the EAM and appropriate personnel for action.

Prescriptive analytics extend the workflow from failure analysis to corrective action. Source: IFS

Distinctive perspective

Prescriptive analytics for asset management extend the value of the more seasoned descriptive and predictive counterparts:

- Descriptive analytics mine historical or current data to produce information that an individual must then interpret and act upon. The timeliness and effectiveness of the corrective action(s) depend on the knowledge and ability of the individual doing the interpretation.

Example: Descriptive analytics presented in a business intelligence dashboard illustrate a supplier’s on-time delivery rates for critical parts over a period of time. Users must decide if the on-time trend is consistent, improving or declining, and if it is time to switch vendors or renegotiate the purchasing agreement.

- Predictive analytics leverage historical and trending data to model and predict what may occur in the future. Maintenance timeliness is improved, but knowing which action(s) to take and when best to take it remains subject to the skills of the responsible individual.

Example: Predictive analytics indicate a motor’s temperature is rising above the normal range and the motor can be expected to fail within 30 days at this rate. Users must decide on the cause of the degradation and what action to take (for improper lubrication, do you correct the lubrication practices, replace the overheated bearing, or replace the motor?), and then schedule the work at the most opportune time before a failure occurs.

- Prescriptive analytics propose actions that are likely to trigger a particular outcome and suggest when to perform them. This approach saves time and avoids the risk of human error since the decision is optimized by a combination of predictive data modeling, statistical algorithms, business rules and machine learning.

Example 1: Prescriptive analytics help to determine what to do about an improperly functioning joy stick for a critical rubber tire gantry crane. Using diagnostic algorithms developed based on asset maintenance history, the solution determines that because the joy stick stutters before it takes off, either the electrical contact needs to be cleaned or the joy stick needs to be replaced. A work request is automatically generated to initiate the corrective action.

Example 2: Prescriptive analytics leveraging past performance and mathematical modeling conclude that deploying PdM for certain additional critical equipment will reduce maintenance costs, improve profitability, and increase overall equipment effectiveness (OEE) by X percent. The recommendation is automatically transmitted to the appropriate personnel.

Kapco Global predicts some challenges for prescriptive analytics deployments in aviation MRO. Source: Kapco Global

Industries stand to benefit

All industries can derive value from the prescriptive approach to asset management, and the airline industry is a prime example. Today’s Internet of Things (IoT) technology allows an aircraft engine’s performance data to be continuously transmitted to the manufacturer, end user airline (owner or lessee), maintenance or reliability service provider, and/or a third-party information aggregator charged with tracking asset performance across industries. All of these parties have some familiarity with how jet engines are performing.

When OEMs retain ownership of engines that are operated by airlines, they may enter into power-by-the-hour contracts that guarantee a minimum number of flight hours or a certain service life. For maintenance, repair, and overhaul (MRO) service contractors that provide engine maintenance services for an OEM or airline, service level agreements (SLAs) commonly detail the performance expectations the customer has for the service provider. Performance data can be used to negotiate and monitor compliance with power-by-the-hour contracts and SLAs.

Similarly, third-party data aggregator companies can collect aircraft engine performance data from multiple information sources, strip out any identifying information, and transmit it to engine owners, operators and service providers, who can then make better decisions about engine operation and maintenance. Aggregators that harness big data in this manner can be found in other industries as well.

This constant stream of sensor data helps to fuel the prescriptive algorithms, ensuring optimal real-time decisions are made and appropriate actions are taken.

Early adopters are leading the way

A reliability leader at a major pharmaceutical manufacturing company is taking steps to phase in a prescriptive approach to asset management. Specifically, the reliability organization aims to improve preventive maintenance, expand predictive maintenance (PdM), and ultimately deliver "smart" maintenance with better condition-based maintenance and prescriptive analytics. If the pilot is successful, the program could go global by 2020.

Maintenance prognostics should encompass overall business conditions and how they affect profitability of asset operation. Source: IFS

Advanced pattern recognition, machine learning algorithms, and online data analysis are part of the IoT platform currently being evaluated for its suitability to pharmaceutical manufacturing. Some of the initial asset targets include positive displacement, centrifugal, and vacuum pumps; capsule presses; air handlers and fans; transmitters; and valve actuators.

The goal is to leverage all available PdM data and technologies (vibration, infrared, ultrasound, oil analysis, and motor current analysis), plus operator-based inspections and historian, distributed control, and external system data. These inputs are brought into a SCADA control system, which then pushes data to a diagnostic machine learning system.

When a machine learning algorithm detects an anomaly, it will generate an alert for validation by an engineer or technician and create a work order in the pharmaceutical company’s EAM system. If the anomaly turns out to be invalid, the machine learning software will be “taught” that the particular condition is normal for that application. Over time, as the prescriptive analytics algorithms become smarter and more efficient, automated decisions and prescriptive maintenance actions will be possible.

The program will be rolled out globally if it is demonstrated that taking raw alarms and other data past the mathematical state, and translating them into usage recommendations, optimizes the effectiveness of the pharmaceutical company’s reliability program.

Challenges to adoption

Kapco Global, an aviation supplies distributor with manufacturing capabilities, sees some challenges inherent in deploying prescriptive analytics, particularly in the aerospace industry supply chain. Among them is the cost of the software and technology plus related training and upkeep. Another is the complexity of gaining FAA approval, since prescriptive approaches would impact aircraft maintenance schedules and other FAA-regulated processes.

“While there are positive indications for efficiency with the adoption of prescriptive analytics, there are some major hurdles to overcome,” explains Vikram Bhatt, COO of Kapco Global (www.kapco-global.com). “MROs would need to make significant investments in the development of sophisticated software, plan for integration with the MRP, and have an analytics group to produce viable interpretation of the information. Widespread adoption of the methodology within aviation may also require extensive regulatory approval.”

Any new technology represents a departure from existing processes, regardless of the industry. Whether and to what extent a company adopts prescriptive analytics for asset management depends on how persistent its champion is – whether that person is a reliability professional, IT leader, or C-level executive.

[sidebar id="6"]