Game on: How the IIoT is transforming asset lifecycle management: Part 2

Digital transformation, the industrial internet of things (IIoT), and smart connected assets have been prominent themes over the past 12-18 months. For the most part, these have been separate focus areas in industrial organizations. In fact, however, they're closely related topics. As pilot projects take hold in a variety of industries, no one industry has the lead; many are finding small wins and value. This is creating a larger opportunity for investments in technology and transformation in 2017. This means that pilots are successful, so expansion into larger asset bases or different parts of the business will occur.

These enabling technologies and related transformational efforts are letting organizations gain competitive advantages. The early adopters of this new paradigm can expect lower overall operations costs thanks to improved asset reliability, longer asset life, and lower decommissioning and disposal costs. What is missing is a discussion of the larger picture of these projects' potential effects on the asset lifecycle and what it all means for operations and maintenance moving forward in the IIoT era.

At the heart of the discussion should be a commitment to understanding everything this new era touches related to the asset. This includes changes in the technology architecture: The asset becomes smart; the workforce becomes empowered; and applications evolve. At LNS Research, understanding the new asset lifecycle era in IIoT is a key focus and we believe emerging technology will continue to play a prominent role in asset lifecycle management.

Click here to read "Game on: How the IIoT is transforming asset lifecycle management: Part 1"

A new way of thinking about the asset lifecycle

Traditionally the asset lifecycle has been viewed as a silo, with only operations and maintenance responsible for "plan, do, check, and act" processes from an asset's design until its death. In an IIoT era, this changes as assets evolve digitally and physically. More touchpoints occur with outside groups that hunger for data that can help manufacturers, suppliers, sales and marketing departments, and customers. This means that we need to think of the asset lifecycle as a platform. The notion of connected platforms comes the consumer world: Think of the success of Facebook, Snapchat, Instagram, What’s App, etc. These solutions ultimately became successful because of the size of connections made.

For industrial platforms to take hold, we need to go beyond IIoT thinking and bring the platform to what’s of value to connecting in the first place – the asset. It’s not just about connecting an asset, adding more sensors, and enabling predictive analytics; it’s about creating as many connections as feasible to that asset throughout its entire asset lifecycle. For social media platforms, this means people, but it's also advertisers, the analytics to direct to whom to send a message, the momentum of stories and collaboration, and getting as many people on the same platform to scale and creating value exponentially.

This means connecting assets, services, workforce, suppliers, manufacturers, sales and marketing, operations, and maintenance together on one platform, with many applications that span specific users or use cases to enterprise apps for many. Following are some of the innovations that begin to emerge in an IIoT era.

As technology has progressed, we have seen an evolution from break/fix reactive maintenance to condition-based maintenance (CBM) and, ultimately, to the holy grail today: predictive analytics. In the past, the prohibitive factor in moving from reactive to predictive maintenance was the high cost of sensors and network connectivity. Now the convergence of cloud and big data is enabling cheaper infrastructure costs, increased flexibility, and greater processing power.

There are two levels to consider when talking about becoming prescriptive. The first is the ability to understand and prescribe which maintenance activity or activities should be taken to postpone or prevent asset failure. The second is the ability to prescribe operational changes to alter the profile of the equipment to delay or prevent the failure. The first is important to become maintenance-smart, while the second enables operational excellence.

Early indicators show that organizations that adapt smart connected assets gain a competitive advantage and can be more profitable in doing so. As asset-intensive industries move from traditional analytics toward predictive and prescriptive analytics, the insights are an opportunity to provide better services. These analytics will incorporate new sources of data, such as video and geospatial data as well as new algorithms via machine learning to further push organizations to evolve into new business models and competitive offerings.

One opportunity is in employing a smart services model with the manufacturer of the equipment you're investing in. This removes the learning curve and makes the manufacturer responsible for monitoring, analyzing, and acting on the asset if it is predicted to fail. The second opportunity is in vendors selling capacity instead of the physical asset itself. Organizations are buying the capability of the machine with guarantees of uptime. This allows companies to become more competitive in their customer base offerings. They can deliver products at a lower price or with a higher level of service because of supplier agreements and confidence in a consistent and reliable manufacturing process.

Moving forward with ALM in an IIoT era

In the pursuit of asset lifecycle management in an IIoT era, it is important to understand potential obstacles. There is a direct correlation between knowledge about new technologies such as the IIoT – an integral component of both smart connected assets and digital transformation – and the ability to build a business case and therefore get the funding required to execute.

A common strategy across all industries is to start small with pilot projects. This approach provides the opportunity to learn about the capabilities available from technology providers and equipment manufacturers as well as what works best for each case and then build a larger future business case. Findings provide the proof needed to address executive leaders' concerns and get their buy-in to fund bigger projects.

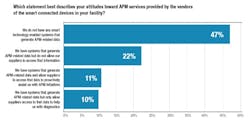

Leveraging data to enable new business models is in its infancy, but we are hearing more customer stories on the opportunity it presents. According to our research, a near-majority of industrial companies, 47%, have not deployed smart connected assets and therefore are not getting the APM data these assets so richly provide. Another split is in the remaining 43% that do have assets generating APM data; more than half of these will not allow suppliers to access it. This is a missed opportunity in companies' relationship with suppliers.

If companies share data, they more than likely will reap benefits like improved product designs and preemptive fixes to support warranty issues. More proactive organizations do at some level share their APM data, either with proactive or diagnostic level support. Starting here allows asset-intensive organizations to understand how suppliers use the data and can be the first step in requesting Smart Services or usage based asset models.

Jason Kasper is a research analyst with LNS Research, which provides advisory and benchmarking services to help Line-of-Business and IT executives make critical decisions across areas including the IIoT, digital transformation, and operational excellence (www.lnsresearch.com/blog). Kasper's primary focus is on asset performance management with collaborative coverage across sustainability, energy management, and IoT/machine-to-machine (M2M) practice areas. Contact him at [email protected].

For the small percentage of forward-thinking companies that have taken advantage of the full smart connected assets opportunity that exists today, benefits are accumulating on multiple fronts. This is apparent in particular from reliability's impact on operational performance, as measured in part via overall equipment effectiveness (OEE).

As the product of availability, productivity, and quality, asset reliability can affect all three of those factors, meaning that organizations with higher reliability will show higher OEE. Looking at organizations that have real-time visibility into APM data vs. those that do not, we see that those that have the capability exhibit a substantially higher OEE performance than those that do not, with a median OEE of 75 vs. 67.

It's all about the platforms

We are in the early phases of transforming asset lifecycle management in this era of IIoT. A thoughtful approach to leveraging these changes is a switch to an operational architecture point of view. As more and more pilot projects lead to success and expand to larger enterprise projects, a more-holistic view will be required to understand the relationships that change and improve within the asset lifecycle. For those ready to act now, here are some key considerations for asset lifecycle management in an IIoT era:

- The IIoT is a transformative technology trend that will change the definition of IT-OT convergence, system architecture, organizational structure, and business models: Smart connected assets, whether legacy or new, will play a crucial role in generating the value of operational architecture.

- Look to vendors that can deliver the needed capabilities of an IIoT platform: They should have an open view of technology platforms, as proprietary capabilities will be arduous to work with long-term.

- Vendor collaboration is critical for delivering on the vision of smart connected assets and operations: There will not be a one-size-fits-all approach, so look to vendors with strong partnerships that can provide a broad reach across the platform.

- Take the first step in the business case journey by preparing technically for what is to come. The best approach for this is a pilot. Understanding at a small scale how things work improves the plan and helps develop the value to move to a larger scale.

- Do not forget people and processes and their connection with operational performance benefits and ROI: As the information begins flowing, new ideas and resources will be required. Processes will change; staying on top of this will extend competitive advantages and can be a value multiplier.

Click here to read "Game on: How the IIoT is transforming asset lifecycle management: Part 1"