What progress are manufacturers making toward smart connected assets?

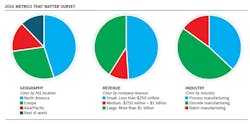

Recently, LNS Research and MESA International completed the fourth edition of the biennial Metrics that Matter research study, which focuses on identifying the key trends within industry and the performance measurements that are driving value for companies today. In this iteration, the evolution of emerging technologies like the internet (and industrial subset) of things (IoT/IIoT), the cloud, and big data analytics was shown to be a substantial factor in how organizations are investing in financial and operational improvements and trying to drive ROI. There were some particularly interesting results on how companies are approaching analytics today and what trends are being seen within the areas of maintenance and asset performance management (APM).

In this article, we’ll dive deeper into the methodology of the study, important trends around awareness and adoption of technology, and how manufacturers are approaching analytics capabilities today to improve APM, minimize risk, and start the transition toward new business models enabled by new levels of reliability and uptime.

Changing view of manufacturing

The traditional view of manufacturing as a series of self-contained islands of automation, expertise, and control is becoming at odds with the situational reality. Both executives and IT staff are taking more interest in the interconnectedness of these areas than has been typical in the past. As the relationship between manufacturing performance and profitability becomes easier to identify and articulate, the C-suite is perking up to how manufacturing can be leveraged to transform business and the bottom line.

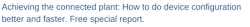

This is seen partly in an examination of who took the current Metrics that Matter survey (N = appx. 250 respondents). With respect to industry, geography, and revenue, the survey breakdown was in line with what we’ve come to expect in our surveys; however, there has been a shift in the individual respondent roles that reflects this evolution in how manufacturing is viewed within the enterprise.

We’re beginning to see more IT and operations management personnel take interest in the survey, while staff are tending to dominate in engineering roles.

Gap in IIoT knowledge is closing rapidly

The skew toward more IT executive participation makes sense given the technology changes coming down the pipeline. There is evidence that the IIoT is starting to factor more into manufacturing considerations, as the survey revealed a large bridging of the gap in IoT awareness and education over the past year: The percentage of survey respondents who indicated that they did not understand the internet of things went from 44% in 2015 to 19% this year. As this education trickles down into investments and implementations, over the coming years the use and sophistication of analytics within and outside the enterprise should continue to grow. Manufacturers already are beginning to use analytics in ways that are advancing maintenance, delivering new value to customers, and enabling new revenue streams/business models.

Analytics use cases inside/outside the enterprise

Not just big data but different data is a key theme as manufacturing software and its use evolves. The survey revealed some interesting use cases of data, both inside and outside the enterprise. While external data sharing instances are concentrated on improving quality and product delivery upstream to suppliers and downstream to customers, 8% of respondents today are sharing data to elevate equipment providers’ maintenance and quality processes.

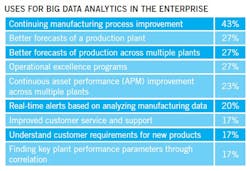

Inside the plant, we see big data analytics used for a broader range and a larger number of activities. Though process improvement takes the top spot, it is clear that manufacturers are putting a high priority on a better understanding of the performance and output within individual plants and across them. Additionally, the focus on continuous improvement specific to APM is garnering considerable mindshare, with nearly a quarter of respondents indicating this.

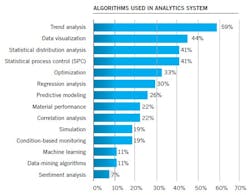

It is positive to see that manufacturers are placing an increased emphasis on APM gains, as it is climbing the priority scale for big data use. When we look more specifically at the types of big data algorithms being used, however, we see that there’s still some work to do in moving toward the type of advanced, predictive, reliability-centered maintenance advocated by LNS Research in architecting smart connected assets, as long-used analytic systems like trend analysis and data visualization top the list and condition-based monitoring and machine based learning lag behind at 19% and 11%, respectively.

The financial component: Monetizing analytics

Looking at how companies are capitalizing on analytics capabilities, we see some encouraging signs of how industry will evolve as smart technology gains a foothold. Survey respondents primarily are monetizing analytics via improvements in production efficiency, but we also see companies leveraging new products and revenue streams through sales of data access and new service offerings. In addition, 14% of respondents say they’ve begun to transform parts of their business by selling products as a service (PaaS).

Advancing analytics for APM

Greg Goodwin a research associate with LNS Research, based in Cambridge, MA. Goodwin writes research papers and case studies and contributes regularly to the LNS Research blog, where he covers topics including manufacturing operations management, industrial automation, sustainability, enterprise quality management software, and asset performance management. Contact him at [email protected].

As research shows, manufacturers are beginning to grasp the potential that advanced technologies like IIoT and big data can deliver in making real-time intelligence available and actionable inside and outside the enterprise. While there is still work to be done in adopting and leveraging the type of analytics that are helping leading organizations build out smart connected assets, we expect that as the IIoT education gap closes and companies move forward into implementation, these capabilities will rise significantly.

At this stage, it’s critical for organizations in the 19% of companies that still do not understand the IoT to cross the knowledge chasm to avoid being left behind by competitors. For organizations that have not already, it’s important to experiment with analytics beyond the plant environment, including new use cases around APM. It has become easy for enterprises to try various cloud, IoT, and big data tools at little or no cost and ensure the involvement of engineering and business data experts so that the variety of data extends beyond typical shop floor data.

For the full results of the 2015-’16 LNS Research/MESA International Metrics that Matter Study, including key challenges by industry, data on financial and operational metric improvements across industries, and details on how manufacturers are evolving their manufacturing software suite to fit evolving cloud models, download a free copy of the eBook “Manufacturing Metrics in an IoT World: Measuring the Progress of the Industrial Internet of Things” at http://bit.ly/1607-MM.