Ideally, key performance indicators (KPIs) are a reflection of a company’s strategic objectives and they compel continuous improvements. In practice, this is not always the case.

KPIs are wholly ineffective if they don’t drive positive change. If the data is not timely enough, the corrective actions are not prompt enough, the wrong information is measured, or no action is taken, their full potential will never be achieved.

Fortunately, there are new, more efficient ways to access KPIs and put them into action. In the past, specialists needed to pull data from multiple systems into a spreadsheet, perform the analysis, and present the data to decision makers. New software and technology options enable a more streamlined approach. Rather than waiting weeks or even months to receive reports, executives can now sometimes instantly receive actionable KPI data and analytics in dashboards and reports. Some software tools even go so far as to identify the root cause of problems and suggest possible solutions.

Some operational intelligence tools deliver real-time visibility into current and forecasted operational issues and even identify likely solutions. Source: IFS

The following experiences of four reliability professionals hint at the many ways KPIs can drive behavior, for better and sometimes worse. A summary of innovative KPI enablers reveals how it is becoming much easier to spur positive change.

KPIs are making a difference

KPIs encapsulate large quantities of information into relevant snippets, making it easier to stay on top of trends, evaluate options, and formulate action plans. Leaders from the C-suite, plant floor, and external service providers need this high-quality information as fast as possible in order to make the best, most timely decisions.

BorgWarner, a supplier of automotive parts and systems, is a very data-driven business. “We keep our finger on the pulse of the manufacturing process by being aware of subtle changes in performance through our KPIs, taking action at the appropriate levels and times to eliminate any possible impact to our quality and productivity goals,” says Wilfred Venet, reliability engineer at BorgWarner PowerDrive Systems.

“We have evolved in my short term with BorgWarner as a result of the extensive use of meaningful KPIs,” adds Venet. “I have seen a cultural growth in terms of communicating opportunities with supporting data from several perspectives, allowing people of various levels in the organization to recognize their potential in contributing toward goals and objectives.”

At CB&I Peruana S.A.C., reliability & CBM leader Victor Manriquez manages according to the KPIs included in his client’s service level agreements (SLAs). “KPIs show us how the maintenance contract that we are involved in is performing in relation to the KPI clauses, and to the values that the client expects as result of our performance. It allows us to look at what measures we have to take in order to meet the contracted KPIs,” says Manriquez.

For instance, if the maintenance backlog values are high, his team will analyze the work orders to determine what kinds of tasks and what equipment are draining their labor resources.

“We are not chasing the KPIs, per se, anymore. We see the KPIs as a result of our actions,” explains Manriquez. “If we find any kind of deviation in the main KPIs, we look to find where to improve in order to manage the deviation.”

Amber Monceaux, reliability engineer at Solvay Specialty Polymers, says that KPI monitoring has had an overwhelmingly positive impact with very few exceptions. “In my previous role as maintenance manager for another polymer manufacturer, we started off way behind the curve. We had no KPIs, an ineffective maintenance management system, and a minuscule maintenance budget. We spent most of our time ‘bailing water,’” she says. Then the company standardized all sites on one computerized maintenance management system (CMMS). “It allowed me to monitor several KPIs – the most significant at that time being storeroom stock-outs and mean time between failure (MTBF).”

Over time, her team was able to reduce the overall stores value and nearly eliminate stock-outs by making changes such as correcting the inventory levels in the system. The tracking of MTBF from their CMMS dashboards revealed a few failure modes that were happening across multiple pieces of equipment, and they very quickly realized where extra time and attention was warranted. Maintenance began to ask the right questions and lead initiatives to solve problems, after which the seeds of a reliability-centered culture began to take hold, she remarks.

Every positively changed behavior had a marked effect on plant reliability and uptime. “The greatest example is how my first maintenance crew transitioned from parts changers to troubleshooters – a change that was relatively easy to accomplish,” says Monceaux. “They used to look to me for direction and would comply, whether it was a good or bad idea. Finally, we began coming together as a team whenever a significant failure occurred and would brainstorm, troubleshoot, plan a solution, and apply a permanent fix. Eventually, this became ingrained in our culture.”

The only somewhat negative experience she had with KPI monitoring was regarding a shift board used to hold each shift accountable for housekeeping. “The areas that were on the board were cleaned, so in that sense the board worked. But in many cases the mess was simply moved to another area,” explains Monceaux. “I guess the lesson here was that KPIs need to evolve over time, especially once you have started to meet your goal in that area.”

James Kovacevic, principal consultant at High Performance Reliability and host of the Rooted in Reliability podcast, agrees that KPIs have the ability to drive changes in behavior almost immediately, but some changes are not always positive. “Negative changes are generally unintended,” he explains. “For example, if the KPI is ‘overtime percentage,’ a supervisor may elect to forgo a Saturday maintenance shift, leaving some preventive maintenance (PM) work orders incomplete. The intention might have been to reduce costs, but maintenance costs will actually increase over time due to poor equipment reliability from reduced PM compliance.”

With properly selected and balanced KPIs, he has seen organizations drive up PM compliance from a low of 63 percent to a high of 95 percent and sustain it. And with proper storeroom KPIs, he has seen a reduction of 30 percent of the storeroom value while service levels improved.

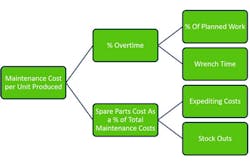

“The key is to connect the KPIs with the individuals performing the work," says Kovacevic, giving as examples "percent maintenance cost per unit" to the maintenance department, "wrench time" for the planners, "overtime" for the supervisors, and "stock turns" for the storeroom. Kovacevic recommends using a KPI tree to help identify role-specific KPIs for department(s) and their associated business objectives.

“KPIs don’t just drive business performance improvements; they have the ability to improve employee morale,” adds Kovacevic. “When employees know what they are measured on, they will work to meet that objective and not feel slighted by performance evaluations.”

Data sources and KPI reporting tools

Most CMMS, enterprise asset management (EAM), and enterprise resource planning (ERP) systems are capable of tracking KPIs to some extent. For more advanced analytics, these systems may be supplemented by business intelligence, performance management, or operational intelligence software.

“Many business intelligence projects fall short because they are not adequately tied to strategic priorities or objectives,” says Chuck Brans, vice president of IFS’s EOI Global Competency Center. “So while KPIs are great, it really comes down to the ability to pull data from an enterprise application that tracks things down to a point of work execution, and then compare that to data from other systems that do not track to that level. Once you can do this, you have a single version of the truth that delivers actionable data in real time.”

KPI Trees help to identify role-specific KPIs for department and business objectives. Source: High Performance Reliability

Though the branding and capabilities of the analytics software may vary, there is some commonality in their purpose. Business intelligence solutions will alert management when a KPI or SLA threshold is nearing, but separate steps may be needed to determine what is causing the problem and why. Performance management is similar in that it will identify where a performance problem is occurring, but may not explain why it is happening or suggest corrective actions. Operational intelligence solutions, on the other hand, strive to alert, explain, and offer prescriptive solutions.

The best analytics solutions capture knowledge from multiple enterprise systems, such as ERP, CMMS/EAM, human resources, contracts, and CRM. They build data relationships and can accommodate embedded algorithms. With time, the software develops its own tribal knowledge.

Advanced solutions also alert managers to threshold breaches with more specificity. For instance, they may point to a resource problem, part problem, or procedure problem. Some will attempt to identify the root cause of the issue, and some may even suggest options for corrective action. These solutions also place focus on the most important processes, so that time and money is no longer wasted making improvements that have little bearing on strategic objectives or the bottom line.

BorgWarner depends on software and dashboards to enable its KPI-driven improvements. “Our selected CMMS provides an intuitive, easy-to-use interface that offers all levels of the organization visibility of relevant data. We also deployed kiosks throughout the facility to allow for ready employee access to load pitch data, providing immediate feedback on area/asset performance,” says Venet.

BorgWarner depends on software and dashboards to enable its KPI-driven improvements. Source: BorgWarner

“I personally like having my maintenance and reliability KPIs as part of the CMMS with dashboards for all users to see,” says Solvay’s Monceaux. “In my present role, this isn't the case, so I'm old-schooling it with spreadsheets and pulling data from a variety of sources to display KPIs.” This method, too, has proven effective for driving positive changes in behavior.

“Our client uses a CMMS for maintenance management,” says CB&I Peruana’s Manriquez. “We have to use it, too, but we are implementing a BI application to feed and analyze the work order data to find more insights about the assets, tasks, and so on. We will use different filters and presentations to fulfill the needs of the different areas of our organization for the maintenance service.”

“A CMMS or BI system will help, even though I have seen successful organizations use only a spreadsheet,” remarks High Performance Reliability’s Kovacevic. “Tools that enable real-time analytics allow the team to identify any issues and take corrective actions before it is too late. Manual reporting and period reporting do not allow this quick response.”

Kovacevic adds a word of advice: “Just remember, if the data is poor, so will be the KPIs. This is why sometimes it is better to focus on the fundamentals and data first, before going after advanced functionality or graphs.”