If reliability excellence (REX) can be implemented at an old smelter like Warrick, with an older workforce with an old-thinking culture, then REX could be implemented anywhere in the world.” They were right. This is our story, one that describes key steps in our journey to ignite a REX transformation in our plant, and how it can happen for any plant or industry that has the strong desire and commitment to do the same.

Building the REX business case

In 2003, the Alcoa Warrick Smelter was 43 years old and had the second highest repair and maintenance (R&M) costs in the Alcoa Smelting System. Asset Reliability in the plant continued to suffer and equipment instability was holding lean manufacturing gains hostage. A formal assessment of the smelter’s R&M efforts identified that a mostly reactive approach was in place with a focus on trying to be really good at emergency breakdown response. Having the second-highest R&M costs among all Alcoa smelters worldwide was a significant yellow flag. Also, although we didn’t know it in 2003, our craft injury rate was an additional flag.

The result of this assessment indicated that implementing a REX program at the Warrick Smelter could reverse these trends. The first task we engaged in was to develop a business case, which identified noteworthy opportunities in the following areas, and included the documentation of high-cost-equipment instability examples:

- What is the plant or industry spending on R&M today?

- What is the plant equipment stability?

- What is the maintenance craft total injury rate today?

- What is the present level of pain being experienced at the plant?

- Are equipment breakdowns keeping the plant from performing at a higher level?

With the help of a REX consultant, it was estimated that our R&M costs could be reduced by 8%, 16%, & 23% over the first three years of REX implementation. We also learned that there are four key REX cost savings levers:

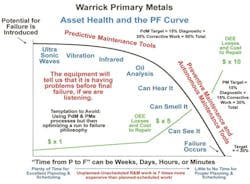

- Running equipment to failure, which is 10 times more expensive than discovering potential equipment failures early with preventative maintenance / predictive maintenance (PM/PdM) techniques.

- Unplanned-unscheduled “emergency” R&M jobs, which are 7 times more expensive than planned-scheduled jobs.

- Planned-scheduled R&M jobs, which have the potential to be 10 times more safe than emergency work because there are less error traps.

- Precision maintenance techniques such as Lube Excellence and Root Cause Analysis of Repetitive Failures, which increase Mean Time between Failures (MTBF).

If a location or industry has been experiencing a lot of equipment instability for a long duration, then it is possible for the cost savings and cost avoidance impact of REX to be even greater.

The importance of REX sponsorship

After building the business case, the next step was to seek both approval and sponsorship for implementing REX at the Warrick Smelter. The primary benefit that we worked to communicate with REX stakeholders and gatekeepers was that a successful REX implementation could reduce or eliminate many risks associated with current maintenance practices, and our business case was approved in due course. However, we recognized that success was not assured just because we earned business case approval; an effective REX Sponsor would be a “must have” for program success.

When the Alcoa Warrick’s REX journey began in 2003, location manager Royce Haws agreed to be REX Sponsor. Interestingly, Royce had attended a one week reliability excellence overview session and while there he was sold on the potential value of REX to lower R&M costs and improve plant OEE performance. When there was an opportunity for Royce to speak before a plant audience or corporate level group, he always showed strong leadership and sponsorship for REX. He liked to highlight R&M cost savings, OEE gains, and reduced craft injury rates the plant had experienced with REX. He continued to be a strong supporter of REX 10 years later until his retirement and by then REX thinking was firmly in place at the Warrick Smelter.

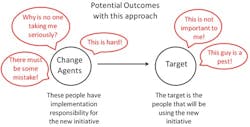

Figures 1 and 2 illustrate the difference that an effective Sponsor can made in helping any initiative to gain traction and succeed. When it comes to REX sponsorship, the participation of a location manager is absolutely critical; without strong plant manager sponsorship, the probability of a successful REX implementation is quite low.

The power of planned, kitted, and scheduled R&M work

Our REX overview included much training on the basic components of REX, with a special focus on increasing our knowledge on planned, kitted, scheduled R&M work. We learned that all R&M jobs that are planned meet the characteristics detailed below:

- An accurate time estimate for job such that the supervisor would have a reasonable expectation on when he could assign next task

- Accurate estimate of needed resources in terms of all craftspeople,

- As well as support equipment like lifts, welders, special tools from the crib, and anything else needed to perform the job.

- Information available like prints, permits, and lockout/tagout (LO/TO) procedures

- Job step sequence, procedure, and instructions to accomplish tasks of the work

- Parts and materials kitted and ready

- Periodically discuss the nature of the job with supervisor and/or craftsperson assigned to complete the job, both as a “Built-In-Check” to assure a quality planned job, and to assure a complete understanding of scope of work and package.

We considered the consequences of putting an R&M job on the schedule that did not meet these planned job characteristics. In such a case, a craft person would be assigned the unplanned job and would need to complete any incomplete steps themselves “on the run”. This opens the door to risks including the craft person being unable to find parts, access special equipment, find prints. and secure equipment from operations, perhaps with LO/TO procedures not being well documented. When would the job be complete? 2 hrs? 3 hrs? 5 hrs? There would be no way to know, because there are no standards for unplanned jobs!

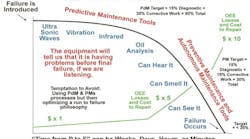

We also found that many plant management teams fail to appreciate the power of using the PF curve (see Figure 3). This curve illustrates the power of finding early anomalies high on the PF curve, and performing early corrective, planned-kitted-scheduled R&M before final failure occurs. If there are no PdM technologies in use, then there can be no PdM corrective follow up work performed. If there are no PM corrective follow up work orders, then all that remains to be performed is emergency repairs. There will be no 7X and 10X cost savings if all the work is performed as emergency R&M.

Key reliability excellence metrics

There are a lot of very good REX metrics available for tracking R&M work. Over the course of our REX journey we began favoring some REX metrics more than others. For example, Total R&M cost lets any plant know the total amount of money on the table to be optimized. R&M cost per unit of production allows for comparison with other plants and that is common in the aluminum industry with aluminum being a worldwide commodity. Of course these are both lagging indicators. We also started calculating Overall Equipment Effectiveness (OEE) for each of our major processes and created a monthly OEE Dashboard.

The leading indicators that we favored the most were Number of Corrective Repairs from PdM and PM. Many plants don’t track these REX metrics, and a common reason is that their CMMS does not have a mechanism to code or track these data. We found a workaround and started inserting "PdG" and "PMG" in the work order description, with the “G” designating a corrective follow up repair. We also developed the OCG code for operator care generated corrective follow up repair. Our total number of corrective PdM and PM follow-up repairs in 2012 was 1,833 each. We figured that every early find we corrected was like a “ticking bomb” defused. Imagine the cost of five of these early finds proceeding to final failure daily, and five more the next day, and so on.

Lessons learned and closing thoughts

With strong sponsorship in 2003, the Alcoa Warrick Smelter embarked on a REX transformation journey. Ten years later at 2013 year-end, Alcoa Warrick Smelter’s R&M costs were 29% below its 2003 pre-REX base (44% lower adjusting for inflation), and OEE performance improvement gains matched R&M savings “1 to 1” for several million dollars in additional savings. A key point is that R&M cost savings were immediately realized, and a large percentage of these savings were reinvested in the facility for a few years to increase asset health and equipment stability.

A formal asset integrity audit performed by corporate level resources in late 2010 determined that the Alcoa Warrick Smelter had the lowest percent of corrective actions needing attention in the next five years versus all other Alcoa smelters worldwide. This audit confirmed that cost savings gains were not from R&M deferral.

At the start of our journey, we didn’t know what we didn’t know about Reliability Excellence. Here is a famous quotation by Dr. William Edwards Deming that describes very well where the Warrick Smelter set in 2003 in regard to REX knowledge.

- Every organization is perfectly designed for the results it gets.

- Profound Knowledge comes from the outside and by invitation.

- A system cannot know itself.

To remedy our lack of practical REX knowledge at the outset, we invited a consultant into our plant to educate us and help speed up implementation. We also embraced Society For Maintenance and Reliability Professionals (SMRP) professional certifications, and by journey's end there were 30 Certified Maintenance & Reliability Professional (CMRP) and Certified Maintenance & Reliability Technician (CMRT) certified engineers working in the Warrick Smelter. Anyone who can pass either of these exams has demonstrated a very good knowledge of REX. We also believe that these professional certifications were a huge Change Management enabler that allowed us to begin to change our 43-year-old plant culture.

In closing, it's my opinion that there is no downside to REX implementation at your location or in your industry. REX is a proven success: the technical science behind REX is sound, and it makes sense. It’s not a 50-50 probability of success once REX systems are firmly in place. The biggest implementation challenges are achieving strong sponsorship and understanding culture change. And the upside is a long-term competitive cost advantage, better enabled lean manufacturing, and improved safety conditions for your craft people.