Asset management and process safety benefit from PAS 55

Energy company ScottishPower, a division of Iberdrola, was the first power generator and the second company in the world to be certified on BSI Publicly Available Specification 55 (PAS 55:2008), which benchmarks best practices in asset management. Ivara’s AssetWise Performance Management software and the Bentley Asset Performance Management (APM) methodology, coupled with the Amor Group Process Safety methodology and KPI dashboard, played a key role in ScottishPower’s achievement. Amor Group was acquired by Lockheed Martin in 2013.

Changes and challenges

“Our vision was one of business excellence in process safety and asset management — good standards of process safety integrated with asset management,” says Martin Sedgwick, head of asset management at ScottishPower. “We put in place a program that had, at its core, business-led projects, a focus on strong leadership, and an overall objective of changing our culture and establishing a long-term commitment to process safety.” A series of industrial incidents, including one at ScottishPower Longannet Generating Station, coupled with the publication of HSE RR509 - Plant Ageing Report, integrity guidelines HSE HSG254, and asset management standard PAS 55 2008 highlighted ScottishPower’s vulnerability to a major incident and the need to make asset management and process safety a priority. In particular, the Baker Panel report into the BP Texas City refinery fire motivated ScottishPower to carry out a self-audit, assessing if a similar catastrophic incident could happen within its operations, and if so, how well could risks be managed.

Pathway to reliability

ScottishPower decided to develop sustainable processes to address the British Government’s Health and Safety Executive HSE Plant Ageing report of 2006 (RR509) and to attain PAS 55 accreditation. It was time to change a very reactive culture in older coal-fired plants to a proactive culture, while at the same time, addressing the future lost knowledge due to employee attrition and the lack of technology to support the approved business model. A roadmap was developed to establish and implement the vision for operational transformation. An aligned IT strategy and system lie at the heart of ScottishPower’s success with the program. A significant amount of groundwork was performed during 2006–2008 to consolidate the business on a small set of best-of-breed applications, including AssetWise Performance Management integrated with IBM Maximo.

AssetWise provided a robust and automated source of data required to derive leading KPIs on a daily basis. And, rather than having many different KPI reporting systems, ScottishPower chose to adopt a unified approach that has eliminated any conflict over data collection. Early on in the program a partnership was formed with the Amor Group to develop an integrated data management system to meet integrity guidelines HSE HSG254. The system aggregates performance data for KPIs from core operational business applications, including AssetWise Performance Management to manage the business and asset integrity.

Operational and maintenance excellence

The scope of the initial implementation included two coal-fired power stations in Scotland and three combined-cycle gas-turbine (CCGT) power stations in England. To enable the organization to ingrain the process of asset management and process safety across multiple plants, ScottishPower leveraged the Bentley APM methodology to guide the implementation through business, organizational, and technology alignment to PAS 55. The complete Bentley APM solution, supported by maintenance task analysis (MTA) failure modes and effects analyses, along with previously completed world-class reliability-centered maintenance (RCM2), and a new internally developed peer-to-peer review practice enabled by the technology AssetWise Performance Management, provided a cohesive and integrated approach to develop, implement, and manage a living program.

Risk management

ScottishPower took a simple view that incidents and near-misses were the single source of lagging indicators. It implemented a new incident management process to capture this data and drive consistent investigation of root causes. Incidents were classified as major, significant, or minor, based on API 754 Process safety performance indicators for the refining and petrochemical industries, related to the underlying 42 risk control systems.

IT and mobile technology

The smart use of IT and use of handheld data collectors running AssetWise Performance Management means data management systems are integrated into process plant and other day-to-day operational systems. This enables the company to drill down from each headline KPI to reveal the underlying causes, trends, and transactions in the Bentley APM methodology. With these core systems, ScottishPower can now assess performance and drive progress toward targets. The information is available to everyone in the company at any time, enabling them to identify and act upon problems within the system before it affects the business or safety. This information is not stand-alone. It is part of a complete system of plant, people, and processes residing within a strong leadership framework where senior management has a good understanding of process safety and asset management that directly links to business performance.

Results achieved

In only two years, ScottishPower successfully established the asset management and process safety framework that has led to improved plant reliability. As a result, it has improved performance and transparency of key processes, as well as experienced fewer unplanned outages and breakdowns with significant cost savings:

- 36% reduction in operations and maintenance costs

- 22% increase in plant availability

- 52% reduction in plant forced outage rates

- 10% reduction in insurance premiums.

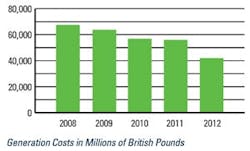

Figure 1. Generation costs dropped from almost 70 billion British pounds in 2008 to just over 40 billion in 2012.

Generation costs dropped from almost 70 billion British pounds in 2008 to just over 40 billion in 2012 (Figure 1). “Ivara helped us to achieve our vision of business excellence in process safety and asset management,” says Sedgwick. As a high-reliability organization, ScottishPower now produces consistently over long and sustained periods of time. The proactive culture is one of continual vigilance and lacks complacency. Employees act strongly to weak signals and set their thresholds for intervening very low, given the understanding of the condition of their assets. Senior management has visibility of core operational processes, which has increased confidence and assurance from board level to plant level. The result has been improved cooperation between leadership, workforce and regulatory bodies and the drive to deliver a high-reliability organization.