The facility in Mountain Top, Pennsylvania, is one of Sapa’s 16 North American locations and is both ISO 14004 and TS 16949 certified, says Paul Zwolan, plant manager. “Sapa’s Mountain Top plant is the company’s key center of excellence for the automotive and renewable energy industries, featuring a full line of value-added services from anodizing to fabrication,” he says.

Mountain Top produces aluminum profiles that are used in a variety of industries, including renewable energy/solar and automotive. The plant has been in operation under several owners since 1971. It was acquired by Sapa in 2009. Today sales are about $60 million, and there are 296 employees.

Effectiveness and efficiency

Zwolan credits the double-digit increases in profitability and sales, with only single-digit increases in staffing, to improved alignment of the operation and customer focus.

Corporate citizenship

Financial results are not the only bright spot in Mountain Top’s performance. “The location has seen a drop in total recordable rate of more than 50% since 2011,” says Zwolan. “This improvement gained much of its momentum in 2012 and throughout 2013, as a result of higher management focus and the effects of a more stable manufacturing environment from the Genesis program, which is based on lean management principles. Disciplines required for Mountain Top’s 14001 certification and our manufacturing excellence go hand-in-hand. Mountain Top has found it to be much more efficient to create a lean manufacturing culture when processes required for meeting ISO 14001 standards are in place.”

As other plants have reported, improved operational focus goes hand in hand with safety improvements.

Recommendations

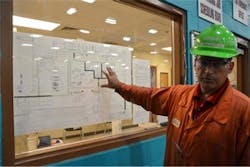

According to Zwolan, management focus is critical to operational improvements. He suggests increased internal communication with employees — one-one-one and in group discussions — a central plant daily management room with a regular meeting time, and daily management presence on the plant floor.

“Focus on the operation and define areas that need improvement,” says Zwolan. “By utilizing employees’ skills, experience, and competence, team members were able to reduce die change time, meet 5S safety objectives, and achieve on-time entries with IMS.”

At the end of the day, improvements must drive customer satisfaction, a safer and more productive workplace for employees, and profitability, says Zwolan. “Sharing letters, emails, and reports from customers thanking Sapa’s Mountain Top plant for its improved service and quality help to motivate the team,” he says. “Sapa’s Health & Safety Day event, scheduled for Sept. 19, will be a special time of celebration for the company’s enterprise and its improved results in health and safety. And finally, all of this has impacted Sapa’s bottom line so successfully that the company’s ownership has told employees that they’ve earned the right to grow by investing significantly in capital projects targeted at our growth markets.”