Australia’s Visy Pulp and Paper (www.visy.com.au) began its journey toward lubrication excellence almost two years ago. Along the way, it has won the John R. Battle Award for Excellence in Machinery Lubrication from the International Council for Machinery Lubrication (www.lubecouncil.org) and increased rotating equipment reliability by 44%. To ensure this is a sustainable improvement, we at Visy have developed a code of practice (CoP) to define the minimum level of performance required to meet the requirements set forth is the Visy corporate policy for machinery lubrication.

Performance relative to the corporate policy and this CoP shall be evaluated by routine gap analysis. Recognizing the importance of machinery lubrication to equipment asset reliability and overall cost of ownership, management diligently commits to correct any identified gaps in performance (Figure 1).

Figure 1. Recognizing the importance of machinery lubrication to equipment asset reliability and overall cost of ownership, management diligently commits to correct any identified gaps in performance.

Lubricant selection and management

Lubricants are selected to match application requirements. A lubricant possesses a collection of physical and chemical properties that ultimately define the lubricant’s performance properties. Depending upon its electromechanical design, each machine has certain lubricant performance requirements that are a function of the forces, stresses, and strains placed on the lubricant. Visy shall, as standard practice, apply appropriate engineering analysis to match the lubricant’s performance properties to the machine’s lubricant performance requirements.

Lubricant inventories are rationalized. Lubricant companies offer a wide range of lubricants that possess a wide range of physical, chemical, and performance properties. While the brand and product names vary widely, most lubricant companies offer lubricant products that are very similar to those offered by competitors. Visy shall, as standard practice, develop generic technical specifications for each lubricant product required and rationalize to store and inventory only one example of the branded product that matches the Visy generic technical specification.

Lubricant stores are well-designed for effective, contaminant-free lubricant transfer. In the chain of custody, lubricants must be transferred from the lubricant supplier, as bulk lubricant or delivered in totes, drums, pails, or cartridges, and then effectively transferred and applied to the machine without cross-mixing or collecting environmental contamination, such as dirt and water. Visy shall, as standard practice, create systems and practices to manage the integrity of each lubricant as it passes from the lubricant supplier to plant stores and ultimately to the machine. These practices shall include mechanisms to prevent cross-mixing, mechanisms to prevent the ingress of contamination, and mechanisms to eliminate contamination ingested during transport and transfer.

Lubricants and lubricating tools are well-marked, employing an intuitive tagging system. Among the most common mistakes that compromise lubrication is cross-mixing, where the wrong lubricant is simply applied to the wrong lubrication point. Typically, this is simple human error. To combat this, Visy has developed an intuitive tagging system that incorporates a color and shaped code scheme that serves to error-proof the lubrication process. Visy shall, as standard practice, apply the Visy standard intuitive labeling system to lubricant storage containers, machine sumps, reservoirs, and lubrication points, lubrication transfer, and other tools, such as filter carts and guns, and any other location where cross-mixing of lubricants is a risk.

Appropriate lubricant transfer and application tools are employed. As with any task, there is a right way and a wrong way to apply lubricants to machines. Common examples of poor practice include open, unmarked, and contaminated buckets and pails, as well as dirty, unmarked funnels. Common examples of good practice include properly marked filter carts pumping the appropriate oil into the sump or tank through a quick-connect fitting and grease guns that are intuitively marked and contain cartridges of the right grease. Visy shall, as standard practice, apply best practices in lubricant delivery and application to ensure that the right lubricant is delivered to the right location free of contamination.

Oil/grease/filter stock min/max levels are known and stock is maintained between min/max levels. Lubricants are a perishable consumable in the plant. Too much lubricant on hand is expensive in terms of inventory cost and runs the risk of shelf degradation. Conversely, too little lubricant on hand runs the risk of a stock-out, which forces expedited procurement and increases the risk that a suboptimal product will be added to the machine as a stop-gap solutions. Visy shall, as standard practice, establish min/max inventory levels through usage analysis for all lubricant and filter products required to service the plant. These levels shall be periodically evaluated for accuracy.

Contamination control

Machines are properly equipped with appropriate vent breathers or other headspace management devices. Contamination enters the machine at any point where the machine interfaces with its environment. The breather is a natural weak point as the machine must inhale and exhale to account for level or temperature changes. A great deal of contamination can enter through this vent if not properly managed. Visy shall, as standard practice, select and maintain headspace management devices that effectively exclude contaminants from entering through the machine’s ventilation systems.

Machines are equipped with proper full-time filtration systems and appropriate beta-rated filters, whether full flow or kidney loop. New oil management, ventilation management, and proper seal selection are all intended to exclude contaminants. However, it’s impossible to exclude all contaminants, and the machine makes some of its own in the form of wear generation. Many machines require full-time filtration or other separation technologies for water removal and varnish removal. These filtration systems may be full-flow or kidney-loop design or a combination of both. The performance of filters is measured in terms of beta rating (capture efficiency), dirt-holding capacity, bypass pressure, and burst pressure. Visy shall, as standard practice, apply engineering analysis to define the appropriate design and combination of filtration and other decontamination technologies and specify the required technical performance characteristics for all filters.

Where appropriate, machines that don't have full-time filters receive periodic decontamination using portable filtration devices. For machines that aren’t equipped with full-time filtration, such as gearboxes, the “drain and fill” oil change has been the traditional approach to contamination control. In most instances, this strategy fails to decontaminate the machine effectively. For these systems, periodic decontamination is a preferred solution that can be accomplished while the machine is running. Visy shall, as standard practice, apply periodic decontamination through quick-connect fittings for systems where full-time decontamination isn’t appropriate. All standards of quality shall be observed for periodic decontamination.

Supplemental decontamination tools are available to address unusual ingress events. Occasionally, unusual ingress events demand supplemental decontamination. This could be in response to component failure shelling out significant debris into the tank or water ingress due to flooding. Visy shall, as standard practice, provide sufficient supplemental decontamination to address unusual events via equipment ownership or hire arrangement.

Greased bearings that are employed in highly contaminated areas are equipped with labyrinth seals to enable frequent greasing as a means to control contamination. Low-speed greased bearings that operate in dirty or wet environments benefit from frequent and excessive greasing to clear contamination from the annulus between the seal and the shaft. However, this strategy doesn’t work where lip seals are employed, as over-greasing simply pushes the seal out, which increases the annulus and induces contaminant ingestion. It is only a feasible strategy where labyrinth-type seals are employed. Visy shall, as standard practice, employ labyrinth or other seals that enable frequent over-greasing of bearings as a means of contamination control where the machines operate in wet and dirty environments. This strategy is never appropriate for electric motor bearings or high-speed bearings.

Oil analysis

Machines have been properly selected for inclusion in the oil analysis program. Oil analysis is a part of a balanced machine condition-monitoring initiative. As with all condition-monitoring technologies, oil analysis has strengths and weaknesses that vary as a function of machine type. A balanced approach includes blending condition-monitoring technologies to assure proactive control of the root causes of failure to extend machine life and to assure predictive detection of machine problems with sufficient warning to plan and schedule action. Visy shall, as standard practice, include machines in the oil analysis program where oil analysis can provide a cost-justifiable contribution to the proactive and predictive goals of the condition monitoring program.

Oil analysis sample valves are properly configured and located. Obtaining a representative sample is the most important aspect of any oil analysis program. Failure to do so leads to false-positive and false-negative conclusions that fail to serve the goals of oil analysis. Visy shall, as standard practice, locate and configure sample valves to enable representative sampling for oil analysis.

The test slate is properly selected to reveal predictable lubricant and machine-failure modes and to enable effective contamination control. Hundreds of tests can be performed on a lubricant. It’s not practical to perform all of them. Visy shall, as standard practice, select for each machine type a slate of oil-analysis tests that delivers the required information to assure that the lubricant can perform as required, that the system’s contamination control goals are being met, and that engineers will be alerted in the event of abnormal wear.

Samples are drawn at a proper interval to enable a timely response to problems. If the interval at which samples are drawn and analyzed is too long, problems can transition from inception to catastrophe inside that interval period. Conversely, sampling too frequently is costly and wasteful. Visy shall, as standard practice, engineer appropriate sampling intervals for oil analysis that considers the inception to catastrophe interval, as well as protection afforded by other condition-monitoring technologies.

Oil analysis alarms and targets are properly set to enable timely response to problems and proactive control of lubricant health and contaminant levels. Oil analysis targets and alarms serve as threshold conditions that warrant action. Targets are goal-based. Keeping particle and water levels at or below the target value extends the machine’s life. Alarms alert us of an abnormal lubricant and or machine condition. Visy shall, as standard practice, develop and enforce oil analysis targets and alarms that are consistent with the organization’s reliability goals.

Oil analysis data are housed in appropriate management software to enable integrated condition-monitoring analysis. Oil analysis is but one dimension of the condition-monitoring initiative. Software facilitates the management and analysis of condition-monitoring data. The analysis process is most effective when the data storage and management is integrated in a single software application. Visy shall, as a standard practice, integrate oil analysis with vibration analysis and other condition-monitoring data for integrated analysis and diagnostics.

Machines are set up to enable effective and non-intrusive inspection of relevant lubrication conditions. The analysis of a lubricant sample is only one aspect of oil analysis. Sensory inspections performed by maintenance technicians or operators are also key to assuring lubrication excellence. Visy shall, as standard practice, set up machines for visual lubrication inspection, such as level, flow, temperature, color, and opacity, and enforce maintenance and operations rounds to ensure effective control.

Lubrication program management

Lubrication PMs are rationalized and clearly written to ensure effective and consistent execution. Machines are commonly over- or under-lubricated. Analysis of many lubrication PMs reveals that the tasks are ineffective, ambiguous, performed at the wrong interval, and, in many cases, unnecessary. Moreover, the instructions provided to maintainers and operators required to perform the tasks are vague and unclear. Visy shall, as standard practice, optimize lubrication PMs to assure that all assigned tasks are value-added, performed at the appropriate interval, and clearly written to enable precision execution.

Time-based lubrication PMs are replaced with condition-driven PMs, where appropriate. Many time-based PMs, such as scheduled oil changes, aren’t required or value-added. In many instances, these tasks can and should be performed on condition in response to oil analysis or other inspection results. Visy shall, as standard practice, endeavor to replace unwarranted time-based lubrication PMs with appropriate condition-based tasks.

When scheduled lubrication PM tasks are overdue, there is a formal notification. Lubricating a plant requires completion of literally hundreds of thousands of individual tasks each year. Compliance is essential. When completing a lubrication route, there are occasions when a task can’t be completed. And occasionally, scheduled tasks don’t get assigned due to other priorities. These tasks can get lost without a formal process to alert managers that these tasks have not been completed. Visy shall, as a standard practice, employ methods to track the on-time completion of every single lubrication PM task and execute a remedial action plan to address missed or overdue tasks.

Lubrication tasks are assigned to lubrication technicians, mechanics, and operators as appropriate. The lubrication policy for each machine class contains a variety of lubrication tasks, some of which are appropriate for assignment to lubrication technicians, such as routine greasing or oil changes; some of which are appropriate for maintenance technicians, such as lubrication during rebuild or repair; and some of which should be assigned to operators, such as daily inspections for level and temperature. Visy shall, as standard practice, assign lubrication tasks in a manner that’s’ appropriate for the task and plant organizational structure to ensure successful task execution.

Training requirements for lubrication technicians, mechanics, operators, managers, supervisors and others are established and executed. Based upon the required tasks in the lubrication policy for each machine and the assignment of those tasks within the organization, the training policy must assure that individuals possess the appropriate knowledge and skills to effectively execute the required lubrication tasks. Moreover, managers and supervisors must possess sufficient knowledge to enable them to support lubrication excellence. Visy shall, as standard practice, enforce a knowledge and skill training and qualification process that’s appropriate to the lubrication requirements for each position in the organization.

Contamination control

When Cemex-Mexico (www.cemexmexico.com), a cement and ready-mix concrete manufacturer, wanted to proactively pursue contamination control by lowering particle count within the oil inside its hydraulic systems, Cemex turned to Des-Case (www.descase.com), which conducted a nine-month comprehensive study on a series of mobile hydraulic systems to determine the efficiency of Des-Case products.

“We initially pitched the trial to Cemex-Mexico because they were looking to reduce the amount of contamination in their mobile hydraulics,” explains Jason Reiner, Des-Case Latin America business manager. ”The Extreme Duty Breather was the best breather option because it is tough enough to handle the rough environment of the equipment, while providing protection against water and even small particles entering the system.”

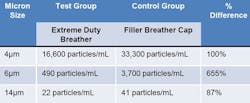

Cemex ran the trial for nine consecutive months, taking frequent readings and recording the status of the breather, equipment, and oil, says Reiner. “Particle contamination was significantly reduced when compared to the traditional breathers,” he says. “Additionally, it also took much longer for the contamination levels to rise than with previous units. While they were pleased with vast improvements in lowering contamination, it did not meet their new target levels. They had set targets for very low particle counts and low levels of water that would be acceptable.”

Six mobile hydraulic systems, classified as the test group, were modified by exchanging the existing filler/breather cap for a Des-Case hydraulic adapter kit and a DC-XD-6 Extreme Duty Breather. Within these six mobile hydraulic systems, the oil was changed, and the reservoir thoroughly filtered with off-line filtration equipment to ensure purification prior to testing.

In addition to the six mobile hydraulic systems, eight other mobile hydraulic systems, six with traditional breathers classified as the control group and two with sealed tanks, were thoroughly filtered to provide equal comparison. Throughout the nine months, the oils were regularly monitored, and particle contamination was measured within these systems.

After nine months of consistent measuring and recording, the DC-XD-6 proved to be a successful solution. Results showed that the test group in which the extreme duty breathers had been installed out-performed alternative products. They not only protected the mobile hydraulic systems from the contaminate that had freely entered the systems previously, but were also an equal match for the considerable amount of vibration, high flow of oil, and rugged environment in which these mobile hydraulic systems normally operate. As the results were finalized, the data showed the test group significantly surpassed the control group.

There are different levels of failure, explains Jason Kopschinsky, senior technical consultant and director of strategic services partners at Des-Case. “If we have a machine, it will eventually break because everything that rotates or reciprocates wears down,” he says. “If you implement the right equipment modification, the failures will be less frequent and the repairs will be less extensive, meaning less downtime and less cost for repair.”

According to Cemex, there were vast improvements in lowering contamination, and the DC-XD-6 did not get close to target levels, especially in the change to the amount of water. “Just putting a breather on a system isn't going to fix anything,” explains Kopschinsky. “If you have oil that’s already saturated with water, the breather will not remove all the moisture. If you continue to do the same things you’ve done, you'll see marginal results. You’ve already got a system that is full of water, so you’re reducing the amount of water and dirt that is coming in by using a quality breather, but you haven't done anything to remove the contaminants and water that is already in the system.”

Kopschinsky recommends taking a holistic approach. “You have to look at the root cause,” he says. “Where is contamination coming from? Is it coming from the system or from an external source? You should perform oil analysis first, to identify if you have water or particulates. The analysis will tell you what kind of contamination you have. Regular oil analysis can also identify which types of contaminants are present in your oil, validating that your program is on track and making it easier to pinpoint if the source of contamination is external or internal.”

If the oil is full of water or not suitable for use, use a filter cart or vacuum dehydrator to remove the water or pre-filter the new oil, suggests Kopschinsky. “Clean the oil and remove the moisture, so that the breather can do its job to reduce the contamination,” he says. “Finally, having the proper system filter on the equipment will help. You should ensure that it is appropriate and meets the requirements of your contamination program. If there is a 50 micron paper filter on the equipment, switching to a 3 micron synthetic filter will be much more effective.”

Off-line filtration

Developments in bulk filtration systems allow filtering of new oils and lubricants to meet OEM specifications for cleanliness levels. But these systems are also proving to be beneficial in upgrading industrial filtration applications.

Take the example of a mine located in northeastern section of Minnesota known as the Iron Range. The existing filtration system, installed decades ago, is used to clean the trunnion bearing lubrication oil as it gets circulated through the reservoir. The trunnion bearings support the ball mills used to grind the ore. It’s a critical application that can also be severe, given the conditions.

Upgrading the existing system was actually driven by the opportunity to address safety concerns. Changing the original system’s filters required two operators removing a very heavy lid and one climbing a ladder and tying off to reach in and pull out and replace each filter element. This also required the draining of the housing, losing hundreds of gallons of expensive lubrication oil.

The other benefits to the upgrade include the advancements in filtration media technology. New synthetic and glass media, which had been developed since the original system went in, have improved both the efficiency and dirt-holding capacity of older systems. This means the entire trunnion-bearing lubrication system can run cleaner for longer periods of time. That cleanliness translates directly into longer life of the system components, reducing the mine’s total cost of ownership.